Active fracturing device for coal rock softening and coal rock fracturing construction process

A fracturing and coal-rock technology, applied in the field of mining engineering, can solve the problems of low fracturing fluid pressure, complex fracturing equipment, poor applicability, etc., and achieve the effects of increasing fracturing energy, good fracturing effect, and reasonable structural design.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

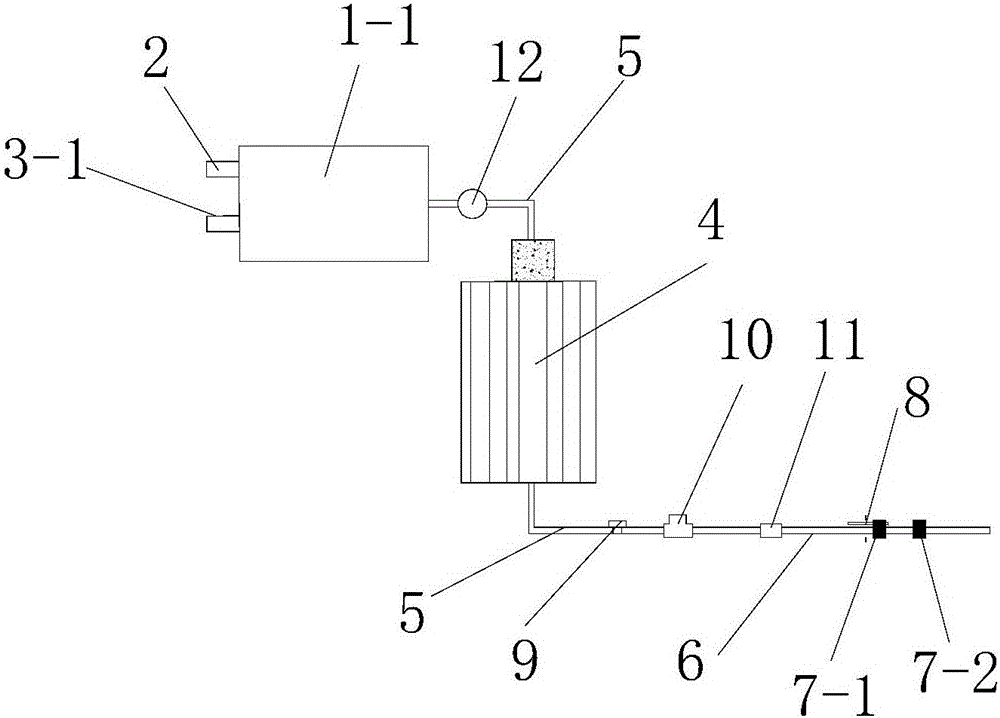

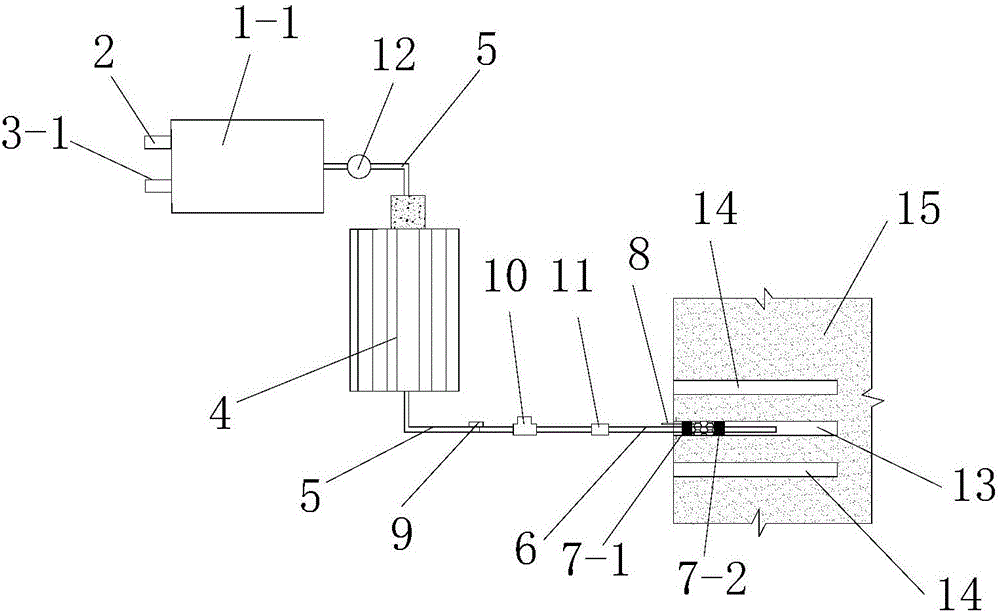

[0058] Such as figure 1 , figure 2 A coal-rock softening active fracturing device shown includes a conveying mechanism and a fracturing mechanism communicated with the conveying mechanism. The conveying mechanism includes a pipeline 5 and a supply unit, a power unit and a regulating unit arranged on the pipeline 5 in sequence. unit, the fracturing mechanism is arranged at the output end of the pipeline 5;

[0059] The supply unit includes a first reactor 1-1, the first reactor 1-1 is provided with a fracturing agent inlet pipe 2 and a dust-proof water inlet pipe 3-1, and the adjustment unit includes a one-way A valve 9 and a three-way joint 10 communicated with the one-way valve 9;

[0060] The fracturing mechanism includes a fracturing pipe 6 that communicates with the pipeline 5 and extends into the fracturing hole 13 of the coal rock 15 to be fractured, and a hole sealer arranged on the fracturing pipe 6. The hole sealer It includes a first sealing capsule 7-1 and a sec...

Embodiment 2

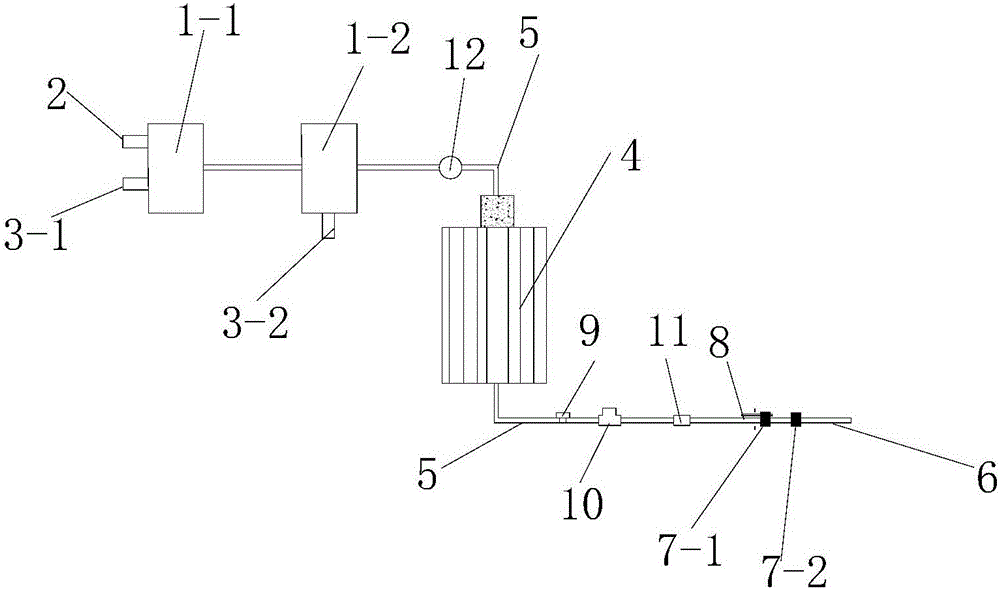

[0089] The difference between this embodiment and embodiment 1 is: as image 3 , Figure 4 In the coal rock softening active fracturing device shown, in the coal rock softening active fracturing device, the supply unit communicates with the second reactor 1-2 of the first reactor 1-1, and the second reactor 1-2 communicates with the first reactor 1-1. A reactor 1-1 is provided with a fracturing agent inlet pipe 2 and a dustproof water inlet pipe 3-1, and the second reactor 1-2 is provided with a supercritical liquid CO 2 Liquid inlet pipe 3-2.

[0090] In actual use, both the first reactor 1-1 (such as tank reactor or jet reactor) and the second reactor 1-2 (such as tank reactor or jet reactor) are used to realize the liquid-liquid reaction process device.

[0091] In this embodiment, the fracturing agent inlet pipe 2 is provided with a control valve for controlling the pressure and flow of the fracturing agent inlet pipe 2, and the dustproof water inlet pipe 3-1 is provide...

Embodiment 3

[0096] Such as Figure 6 Shown, utilize the coal rock softening active fracturing device of embodiment 1 to carry out the construction technique of fracturing coal rock, this technology comprises the following steps:

[0097] Step 1. Preparation of fracturing fluid and drilling:

[0098] Step 101, the preparation process of dust-proof water fracturing fluid: send the fracturing agent into the first reactor 1-1 through the fracturing agent inlet pipe 2, and simultaneously feed the dust-proof water through the dust-proof water inlet pipe 3-1 Send it into the first reactor 1-1, and mix it uniformly to obtain dust-proof water fracturing fluid; the pressure in the first reactor 1-1 is 7.8MPa, the temperature is 31°C, and the flow rate of the fracturing agent is 0.1L / h, the flow rate of the dust-proof water is 5L / h, and the mixing time of the fracturing agent and the dust-proof water in the first reactor 1-1 is 1min;

[0099] Step 102. Drilling: Drilling: use a drilling tool to dr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com