Drainage construction method for tunnel passing through clastic rock steeply inclined reverse thrust water-rich fault

A technology for tunnel drainage and construction methods, applied in drainage, tunnels, earth-moving drilling and mining, etc., can solve problems such as catastrophic consequences, affecting construction safety and efficiency, and slow construction progress.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

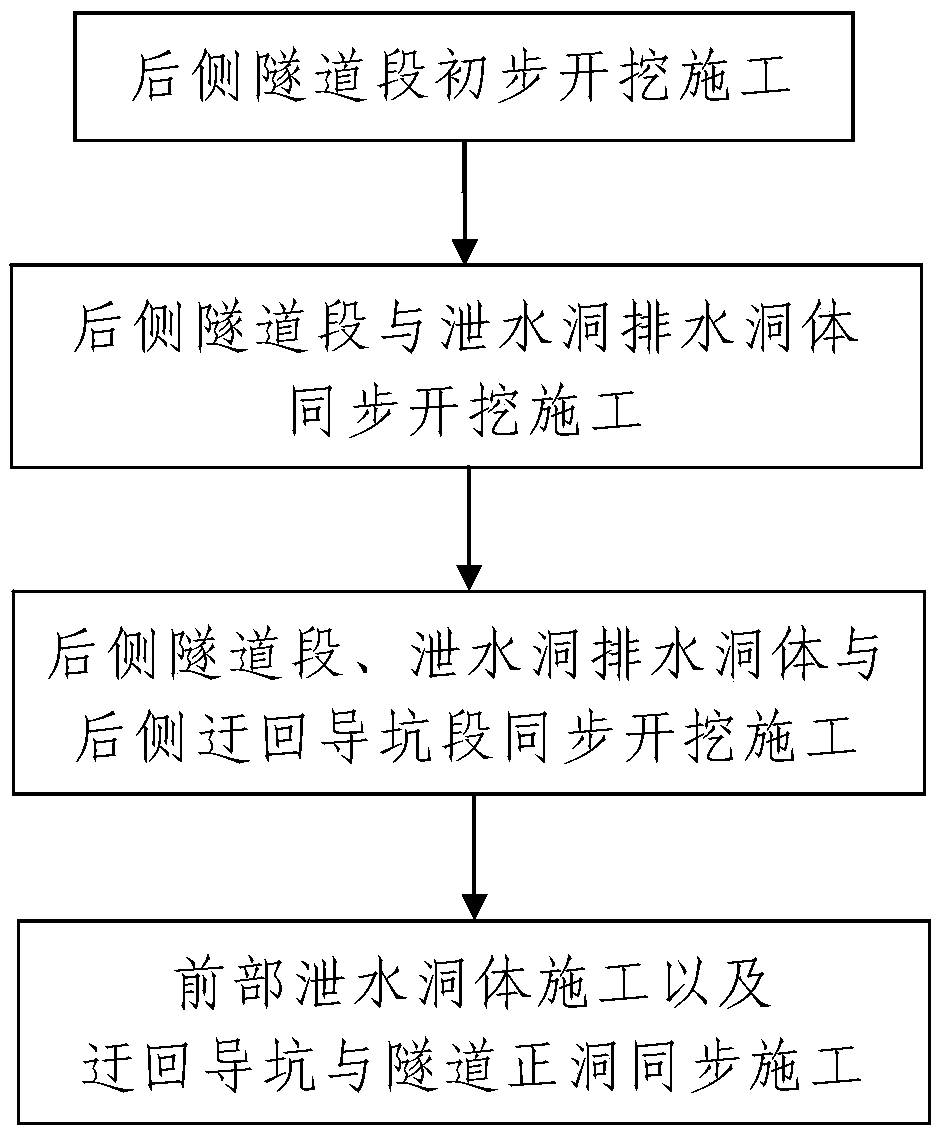

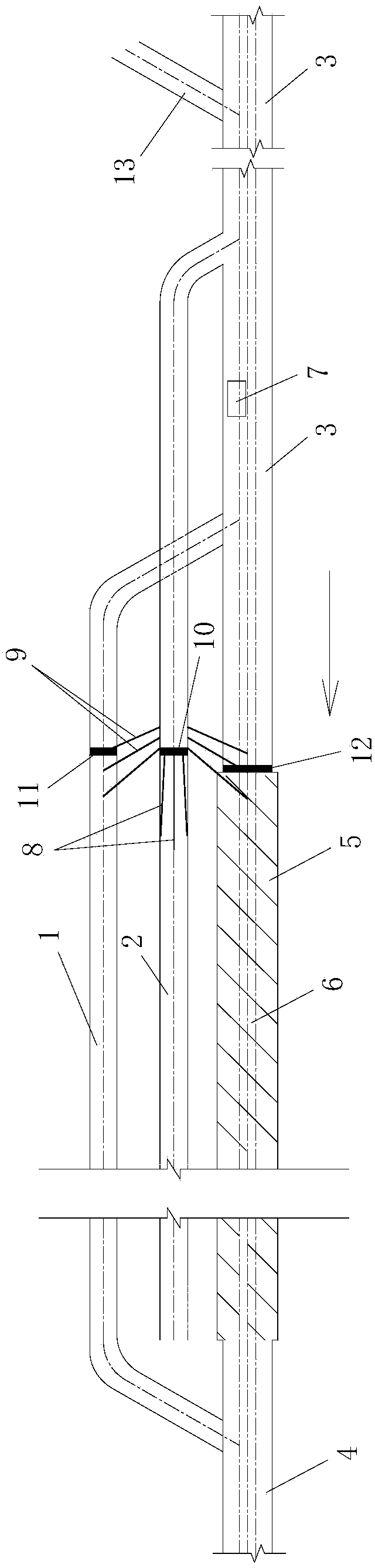

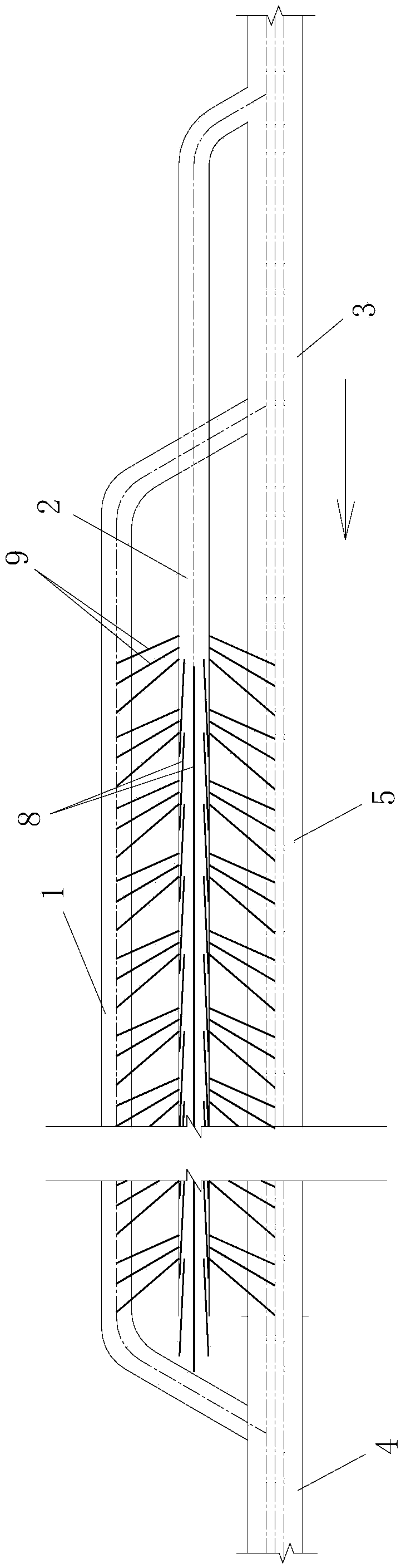

[0095] Such as figure 1 Shown is a drainage construction method for tunnels passing through steep clastic rock thrusting water-rich faults. The main tunnel of the constructed tunnel is divided into a rear tunnel section 3, a front tunnel section 4 located in front of the rear tunnel section 3, and a connecting tunnel section. The middle tunnel section 5 between the rear tunnel section 3 and the front tunnel section 4 and passing through the clastic rock steep thrust water-rich fault 6, see figure 2 , image 3 and Figure 4 On the same side of the tunnel being constructed, there is a roundabout pilot pit 1 and a drainage tunnel 2, both of which pass through the clastic rock steeply dipping water-rich fault 6 from the back to the front. The tunnel hole; the detour guide pit 1 is a detour guide pit excavated between the rear tunnel section 3 and the front tunnel section 4, and the detour guide pit 1 and the main tunnel of the constructed tunnel are laid in the same On the hor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com