Reverse construction method for pebble foundation swirling well

A construction method and technology of whirlpool wells, which are applied in infrastructure engineering, excavation, construction, etc., can solve the problems of difficulty in guaranteeing quality requirements and many potential safety hazards, and achieve the goal of reducing expenses, labor intensity, and construction costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

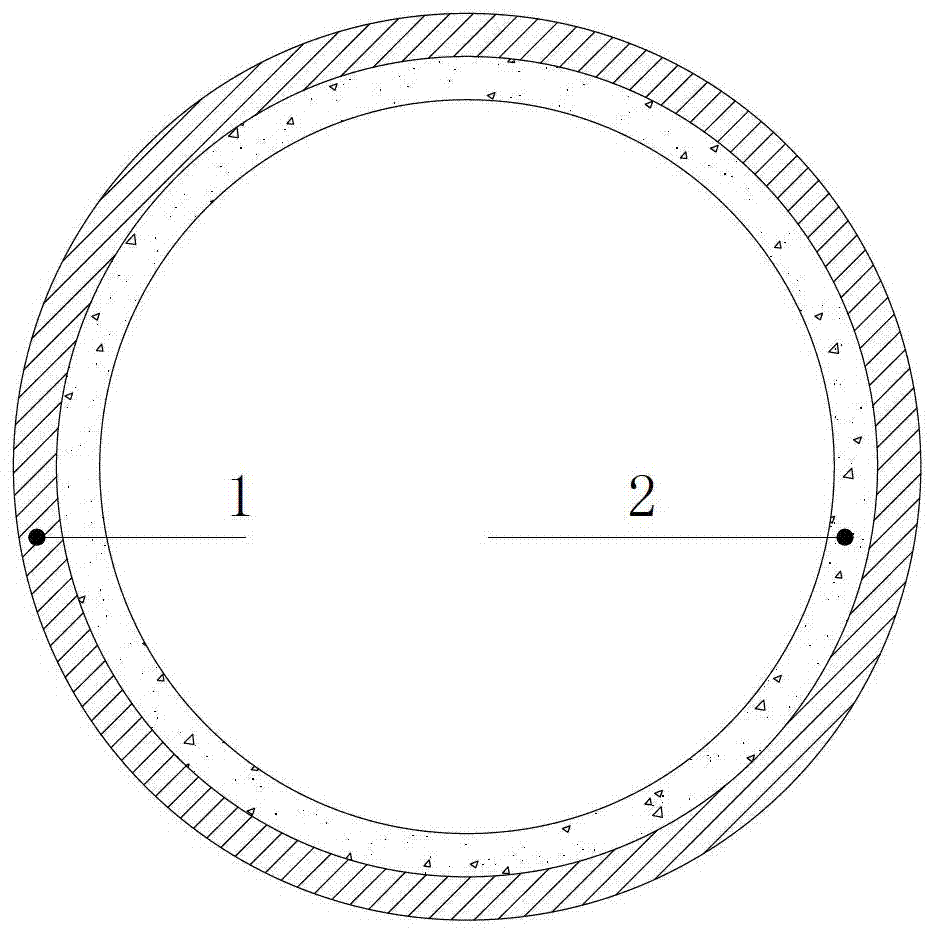

[0022] see Figure 1 to Figure 4 , a pebble foundation swirl well reverse construction method, comprising the following steps:

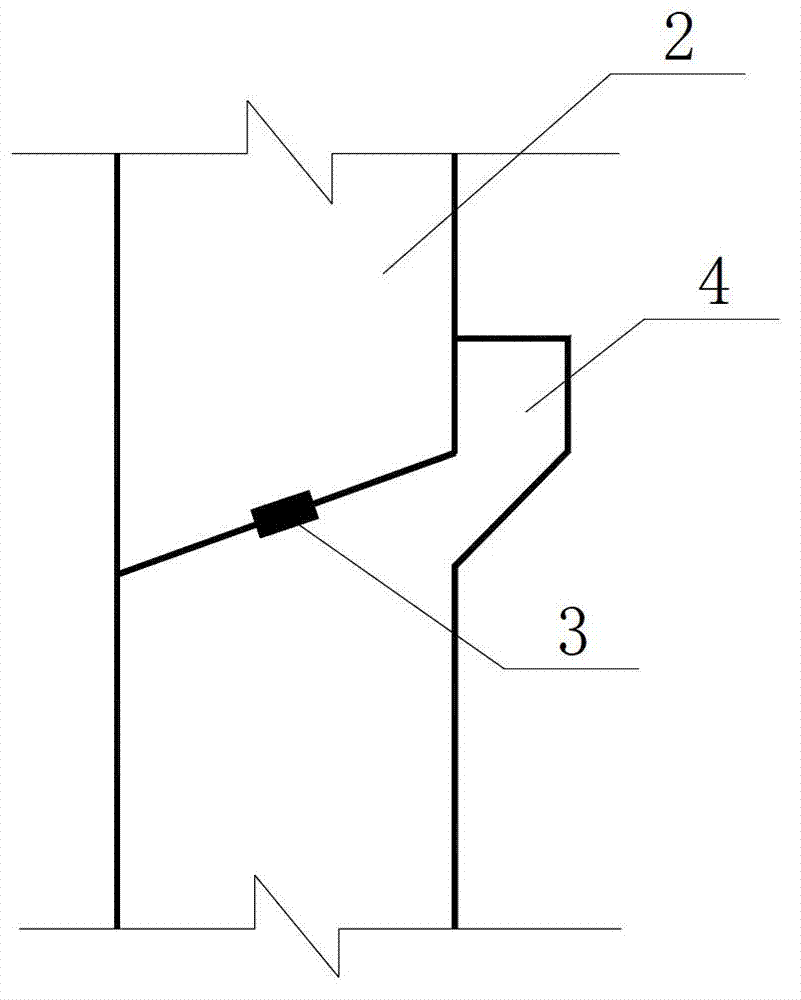

[0023] 1) Measurement and positioning to determine the positions of the center of the swirl well, the well wall 2 and the crown beam 1;

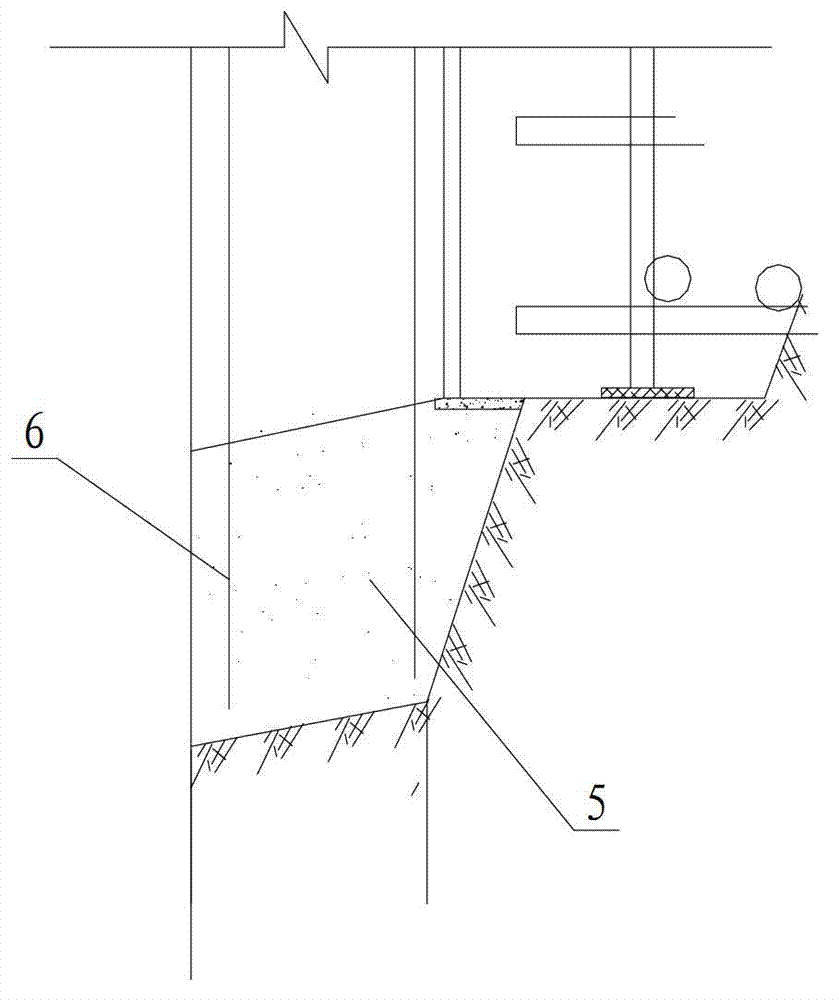

[0024] 2) Excavate the earthwork to form the foundation pit of the first section of the well wall and crown beam 1, and form a first annular groove at the bottom of the first section of the well wall foundation pit corresponding to the second section of the well wall to accommodate the first The lower end of the shaft wall reinforcement is vertically reserved reinforcement 6;

[0025] 3) Binding the steel bar of the crown beam and the steel bar of the first section of the well w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com