Acquisition method of sliding pressure curve of steam turbine by using main steam flow as scheduling variable

A technology of main steam flow and sliding pressure curve, which is applied in the directions of mechanical equipment, engine components, machines/engines, etc., to achieve the effect that the determination method is simple and easy to implement and easy to implement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

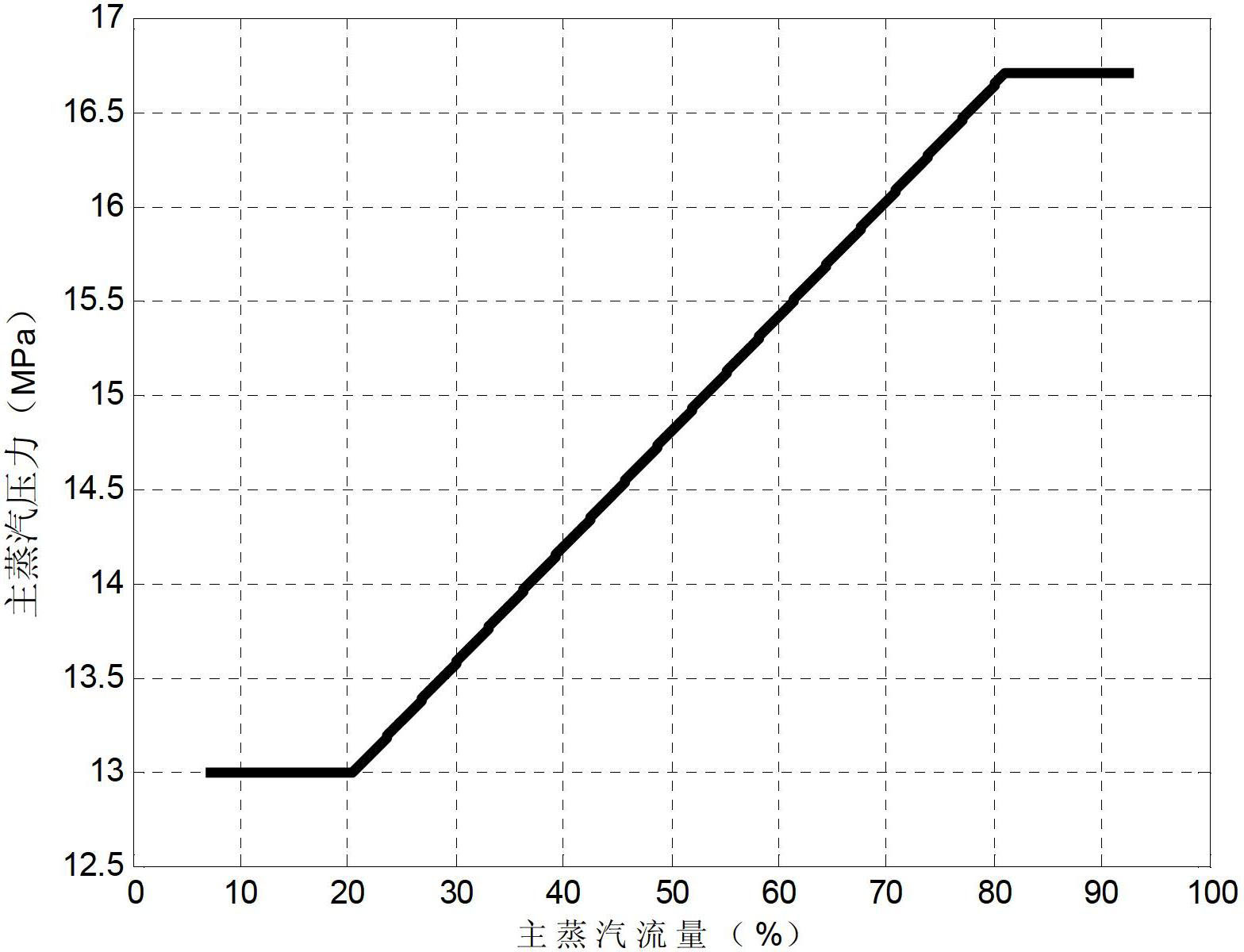

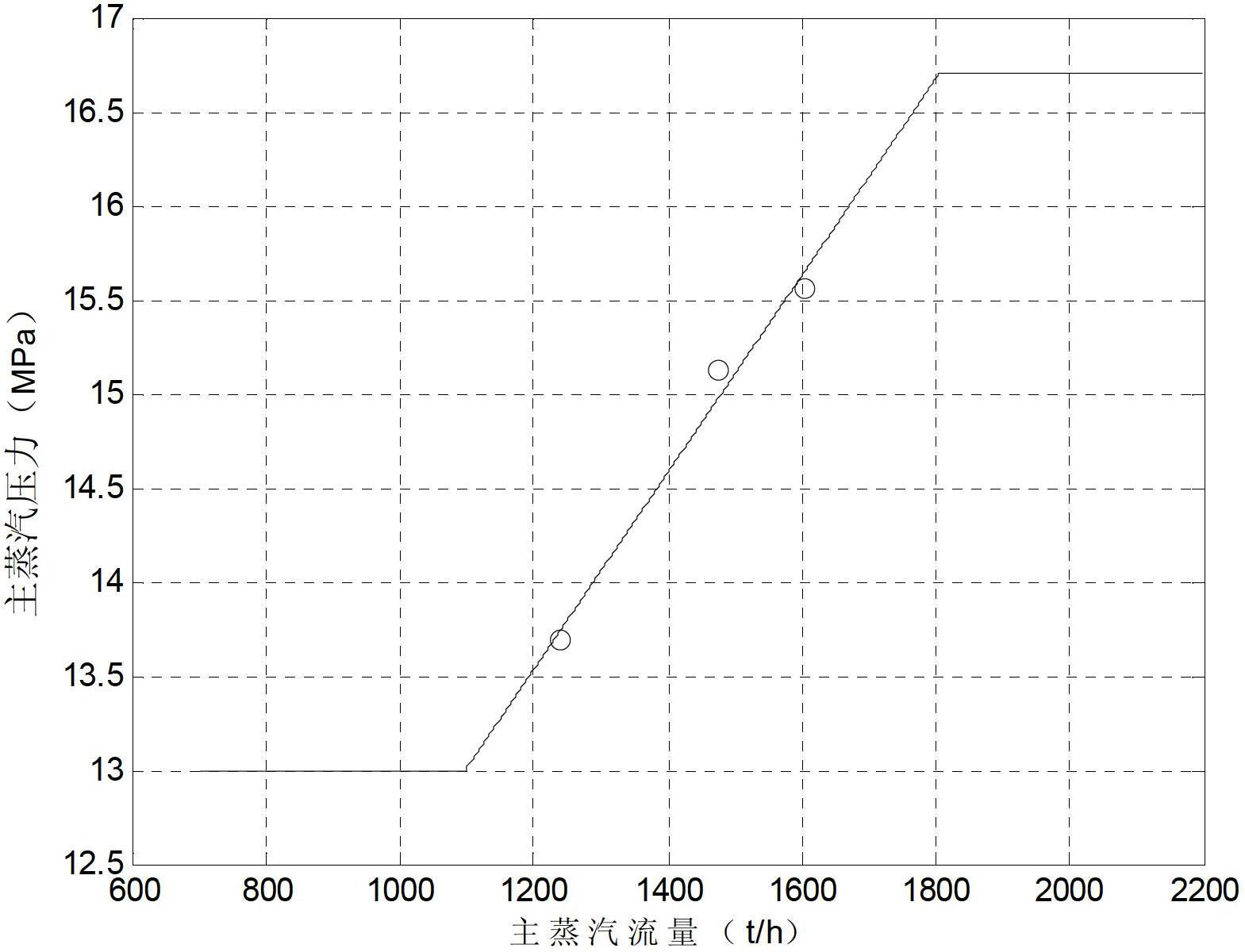

[0020] Specific implementation mode one: the following combination Figure 1 to Figure 3 To describe this embodiment,

[0021] A method for obtaining the sliding pressure curve of a steam turbine using the main steam flow as a scheduling variable, the implementation steps of the method are as follows:

[0022] Step 1: According to the type of heating and extraction steam unit, select M main steam flows according to the order of main steam flow values from small to large; M is an integer greater than 2; perform the following step 2 for each main steam flow to four, then go to step five

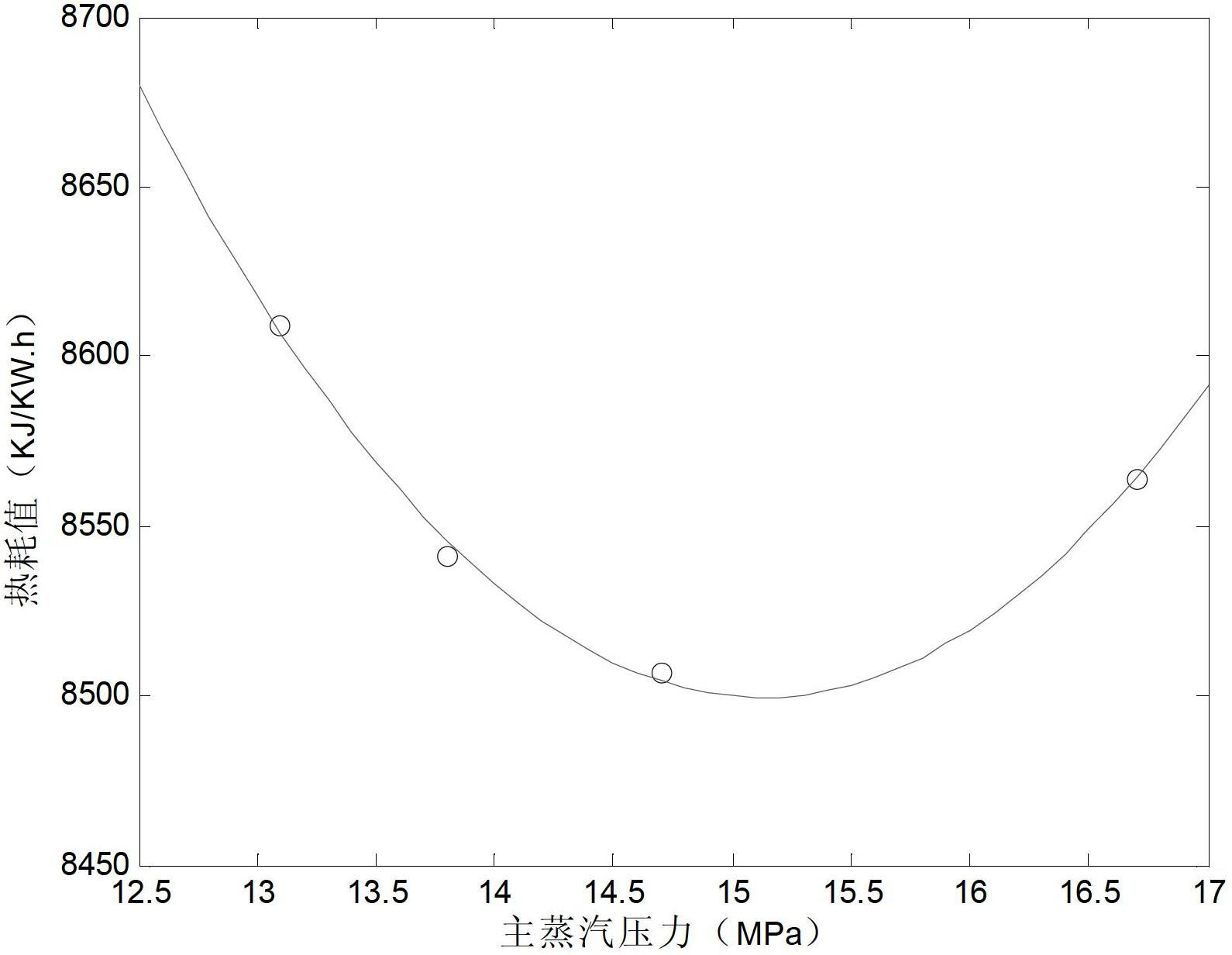

[0023] Step 2: Under the selected main steam flow rate, keep the heating and extraction steam volume and the vacuum of the condenser unchanged under the main steam flow rate. The main steam flow rate is selected from N different main steam pressure values of the heating and extraction unit, and N is an integer greater than 4;

[0024] Step 3: At each main steam pressure, keep the main st...

specific Embodiment approach 2

[0033] Specific implementation mode two: the following combination Figure 1 to Figure 3 Describe this embodiment. This embodiment is to further explain the calculation of the unit test heat rate corresponding to each main steam pressure set value described in step 3 of the first embodiment. The method for determining the sliding pressure curve of the steam turbine, the method for calculating the unit test heat rate corresponding to each main steam pressure setting value described in step 3 is:

[0034] According to the calculation formula of heat consumption value:

[0035] H rt = F ms × H ms - F fw × H fw - F shsp ...

specific Embodiment approach 3

[0037] Embodiment 3: This embodiment is a specific process of obtaining the sliding pressure operation curve of the heat supply and steam extraction unit from the method described in the present invention.

[0038] In this embodiment, the heat supply and steam extraction unit is a thermal power steam turbine unit of a 600MW unit, and the process of applying the method of the present invention to obtain the steam turbine sliding pressure curve is as follows:

[0039] Step 1: Select the main steam flow rate as 1230t / h, 1450t / h, 1600t / h, 1700t / h respectively, and keep the heat supply and extraction steam volume and condenser vacuum constant under one main steam flow rate; for each main steam flow rate For steam flow, perform the following steps 2 to 4 respectively, and then perform step 5

[0040] Step 2: Change the main steam pressure of the unit under the main steam flow rate of 1230t / h. The specific values of the main steam pressure points are as follows:

[0041]

[004...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com