Experimental method for building forming limit diagram of transformation induced plasticity steel plate

A technology of phase change induced plasticity and forming limit diagram, which is applied in the direction of material inspection products and test metals, etc., can solve the difficult problems such as the position of forming limit failure of TRIP steel plate and the judgment of formability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

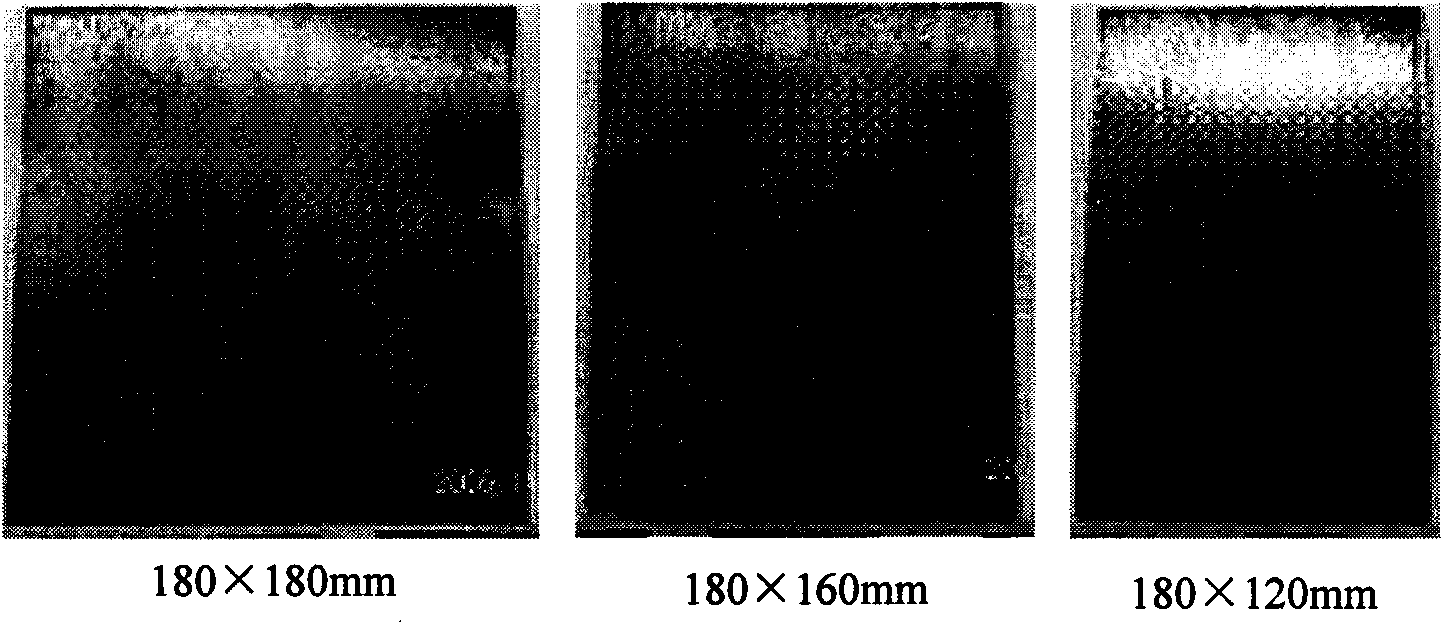

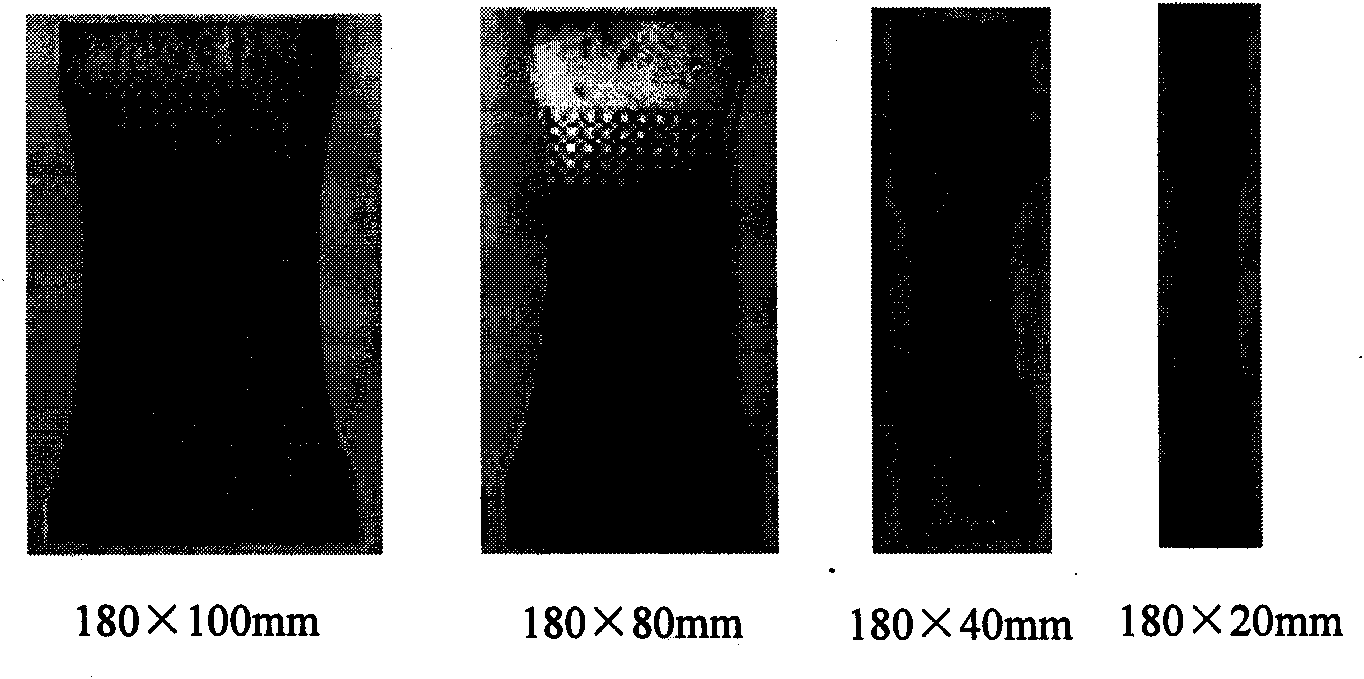

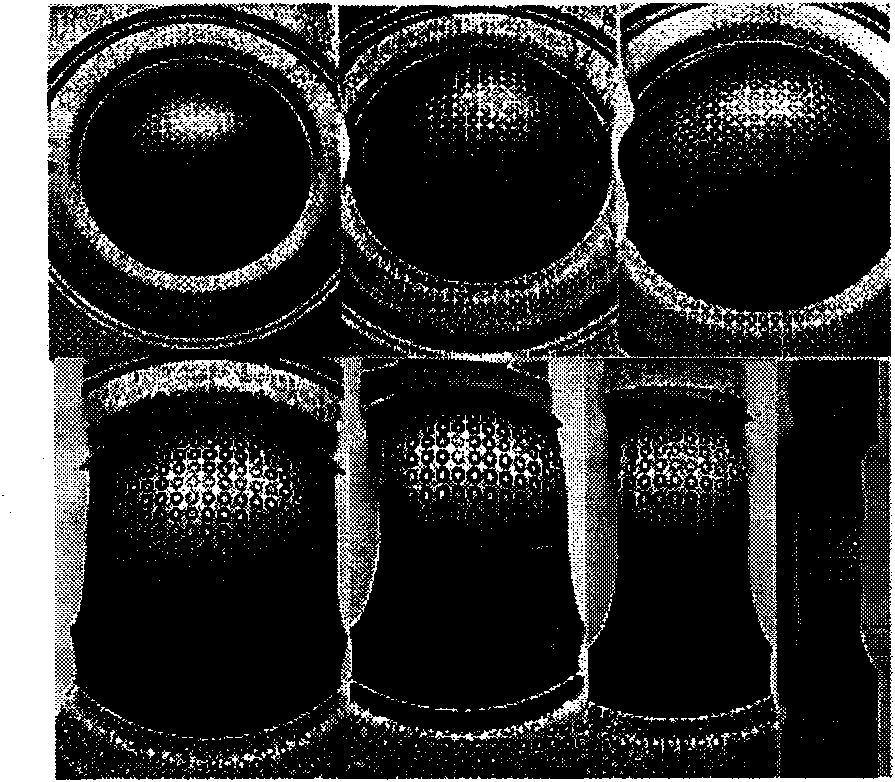

Embodiment 1

[0029] Firstly, a phase transformation-induced plasticity steel plate is prepared, the steps are: smelting low-carbon silicon steel into steel ingots, and smelting low-carbon low-silicon steel into steel ingots, the chemical composition of which is C0.18%, Mn1.38%, Si0.67%, Al0.56%, P0.0075%, S0.0048%, Nb0.014%, and the balance is Fe. After the steel ingot is kept at 1200°C for 1.5 to 2 hours, it is forged into a 30mm thick forging billet. Hot rolled to 3.5mm thick and then cold rolled to 1.0mm thick. The cold-rolled steel plate was kept in sodium chloride at 800°C for 5 minutes, then quenched into potassium nitrate at 400°C for 5 minutes, and cooled to room temperature in air to prepare a low-carbon and low-silicon TRIP steel plate. Then the steel plate is prepared into samples of different specifications and sizes, and the photos of the samples are as follows: figure 1 As shown, the length is 180mm, and the widths of wide strip samples are 180mm, 160mm and 120mm respective...

Embodiment 2

[0035] Firstly, the phase change induced plastic steel plate is prepared, the steps are: low carbon high manganese steel is smelted into a steel ingot, and its chemical composition is C600ppm, Mn23.8%, Si3.0%, Al2.7%, and the balance is Fe. After the steel ingot is kept at 1150°C for 1.5 to 2 hours, it is forged into a 30mm thick forging billet. Hot rolled to 5.0mm thick and then cold rolled to 1.0mm thick. Heat the cold-rolled steel plate to 1100°C for 15 minutes, then water-cool to room temperature. Prepared into high manganese TRIP steel plate. Then the steel plate is prepared into samples of different specifications and sizes, the method is the same as in Example 1.

[0036] The method for establishing the forming limit diagram of the TRIP steel plate is the same as in Example 1, wherein the organic solvent used for sample cleaning is acetone, and the forming limit diagram of the TRIP steel plate is as follows Figure 6 shown. From Figure 6 It can be seen that the FL...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com