Manufacturing method of laser impact sheet forming limit diagram and data acquisition device

A forming limit map and laser shock technology, applied in laser welding equipment, manufacturing tools, welding equipment, etc., can solve the problems of inability to obtain the forming limit map of laser shock sheet metal, and inability to predict and control the high strain rate formability of laser shock waves. , to achieve the effect of avoiding excessive impact phenomenon, low cost and short preparation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Such as Figure 4 , 5 shown.

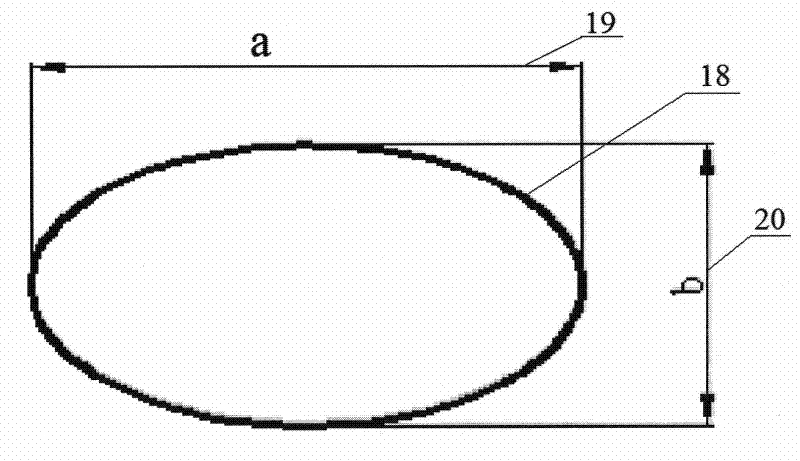

[0027] A method for making a laser shock sheet forming limit diagram, comprising data collection and drawing a sheet forming limit diagram, the data collection comprising the following steps: (1) placing a sheet printed with a circular grid on an elliptical concave On the mold, move the blank holder ring with calendering ribs down and make the sheet enter the calendering groove, apply the blank holder force on the blank holder ring, so that the sheet material is crushed to death; (2) apply a vertical laser on the center surface of the sheet material For impact load, use the optical power meter as an instrument for checking the breakage of the sheet metal. When the digital display of the optical power meter shows the continuous red light emitted by the red light, stop the laser impact and take the sheet material out of the elliptical die; (3 ) On the sheet metal, select the grid with the largest deformation and an ellipse after deformatio...

Embodiment 2

[0039] Such as Figure 1-5 shown.

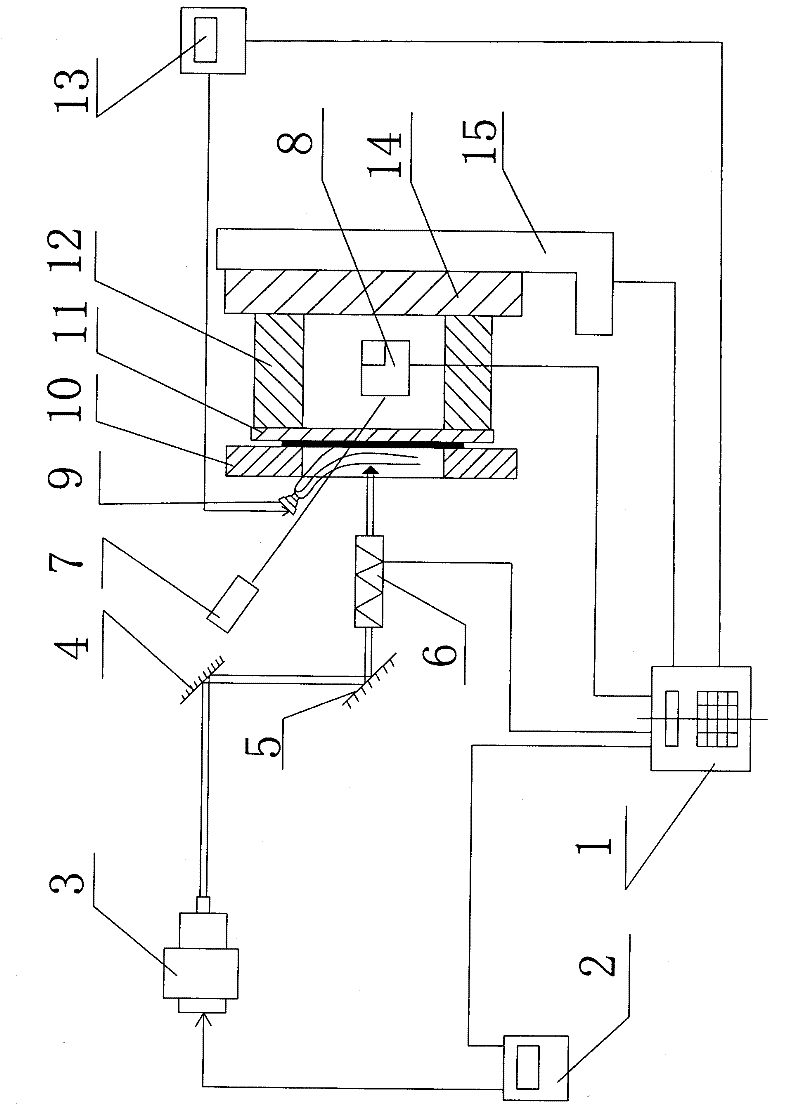

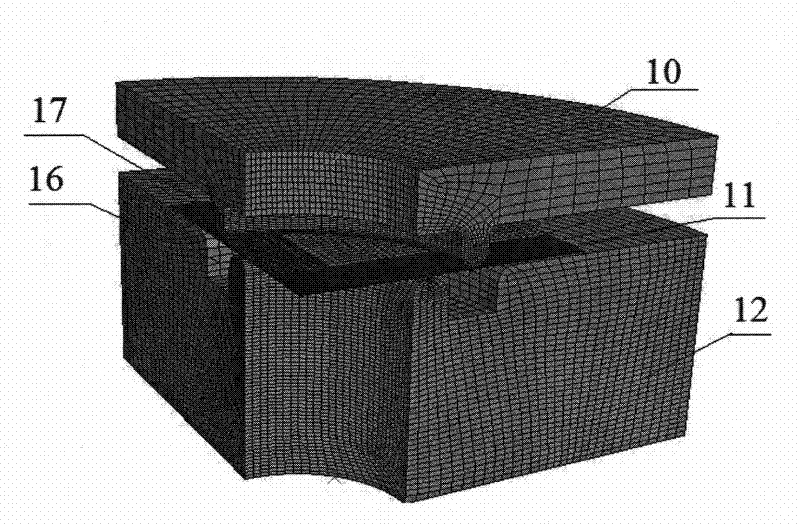

[0040]A kind of laser impact sheet metal forming limit diagram production data acquisition device, it comprises central control processor 1 (composed of CPU and corresponding control program and conventional peripheral circuit), laser controller 2 (laser supporting parts, can be matched by the laser manufacturer) Provide), repetition frequency pulse laser 3, external optical path system 4, spot adjustment device 6, red light 7, optical power meter 8, multi-axis coordinate table 14 and coordinate axis rotation controller 15, central processing unit 1 and laser control respectively Device 2, spot adjustment device 6 (mainly made up of optical components such as lens, magnifying glass, total reflection mirror. Can adopt existing technology to realize), optical power meter 8 (can be purchased directly from the market) and coordinate axis rotation controller 15 ( Can directly adopt the similar device on the existing machine tool) to be electrica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com