Testing device and testing method for forming limit diagram under high-temperature constant-strain rate condition

A technology of constant strain rate and forming limit diagram, which is applied in the direction of applying stable tension/compression to test the strength of materials, so as to eliminate the strain rate factor and facilitate research

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

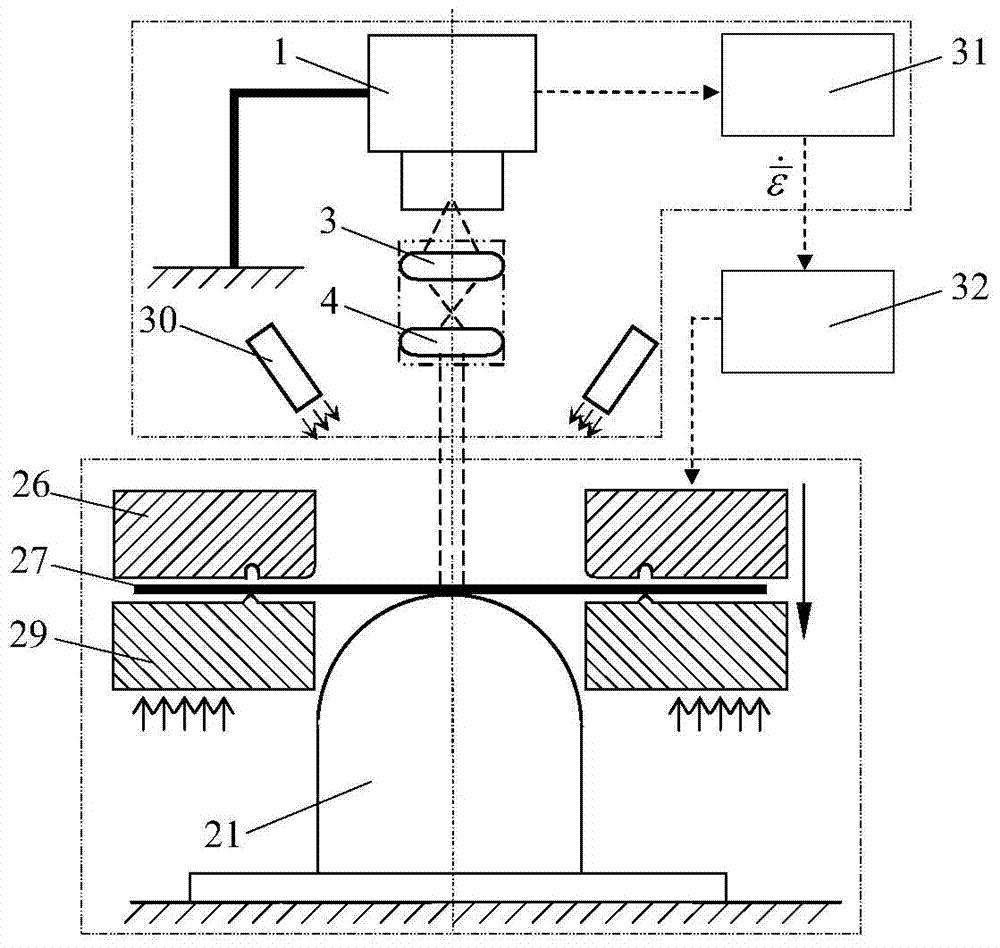

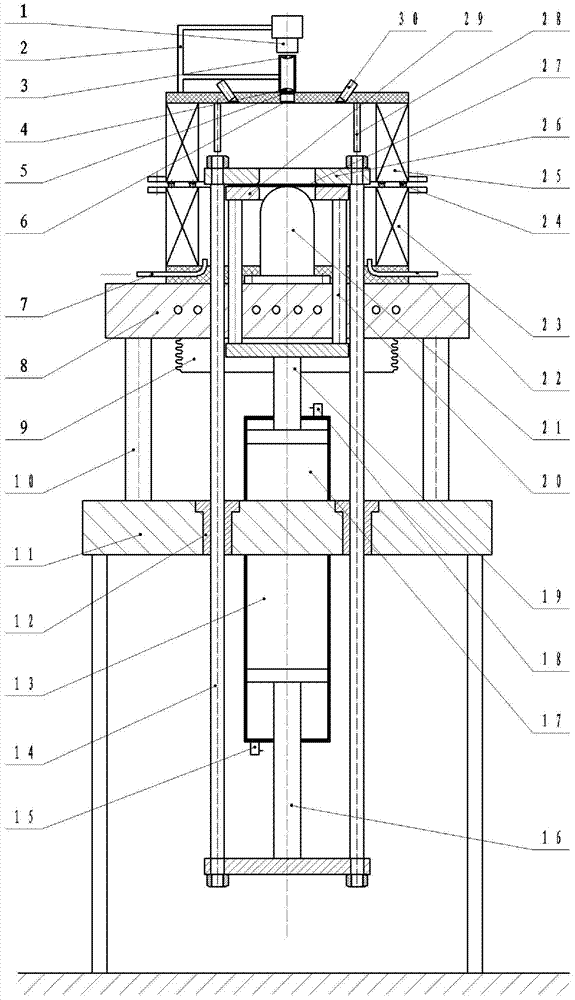

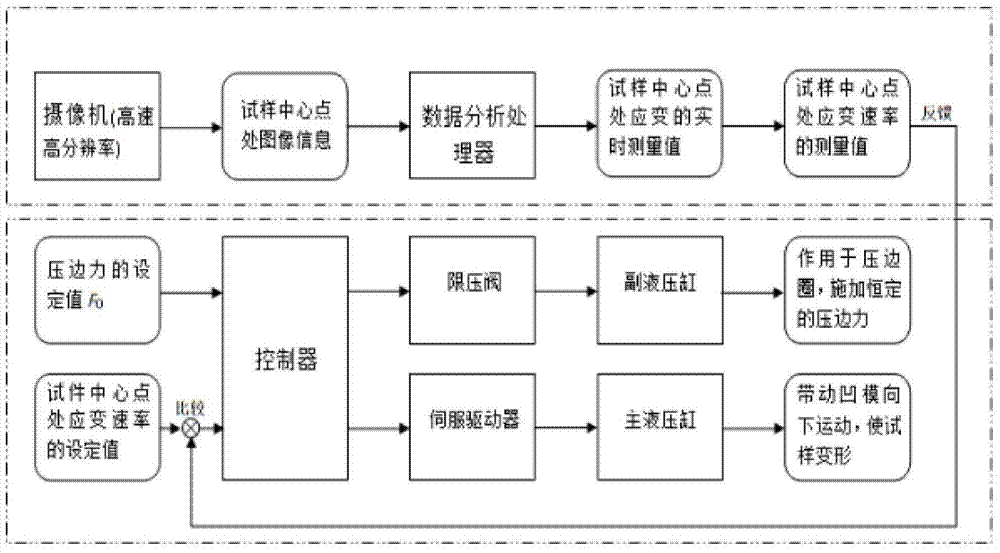

[0047] refer to Figure 1~3 , a testing device for forming limit diagram under the condition of high temperature and constant strain rate, including a sample deformation pressure device, a real-time strain measuring device and a controller;

[0048] The sample deformation pressure device includes a base 11, a workbench 8 fixed on the base 11 through a column 10, a main hydraulic cylinder 13 fixed on the lower end surface of the base 11, and an auxiliary hydraulic cylinder fixed on the upper end surface of the base 11. Cylinder 17, pull rod 14 that is inserted on base 11 and workbench 8 and is slidingly fitted with it, die 26 that is fixedly connected to the upper end of pull rod 14, and the lower end of pull rod 14 is connected with the main piston rod 16 of the main hydraulic cylinder 13 The blank holder 29 provided with the drawbead at the l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com