Testing system and method of plate high temperature forming limit diagram

A forming limit diagram and high-temperature forming technology, which is applied in the field of sheet metal forming, can solve the problems of unevenness, high thermodynamic performance requirements of punch and die materials, difficulty in maintaining rigidity of punches and dies, etc., and achieve the effect of simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

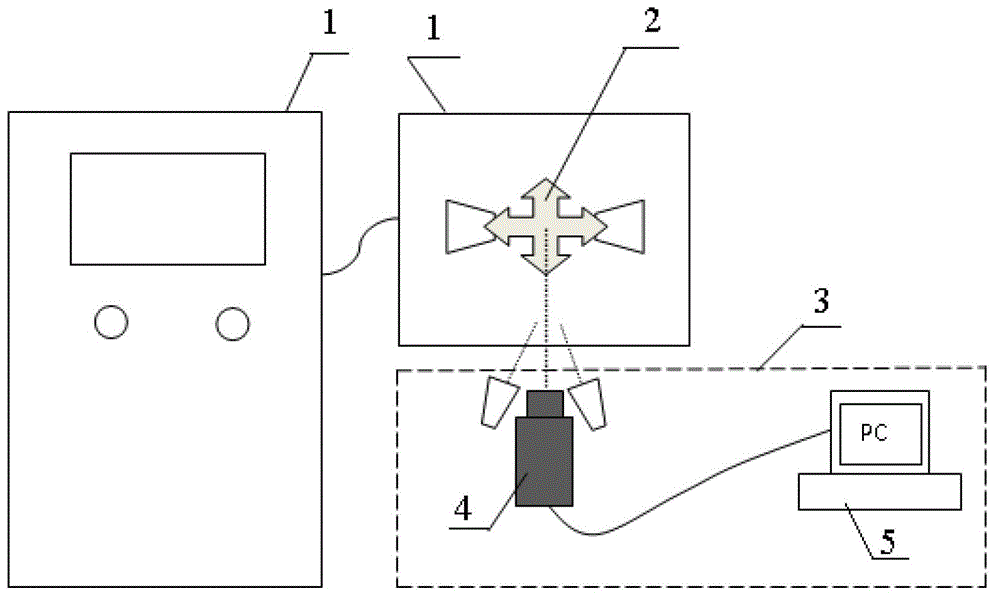

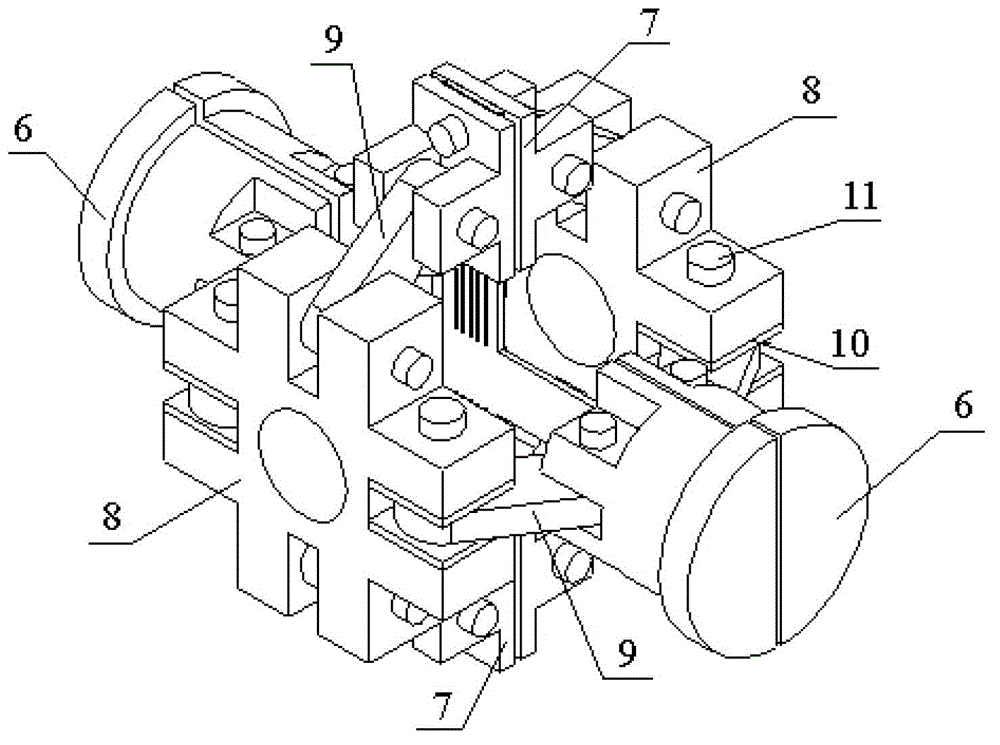

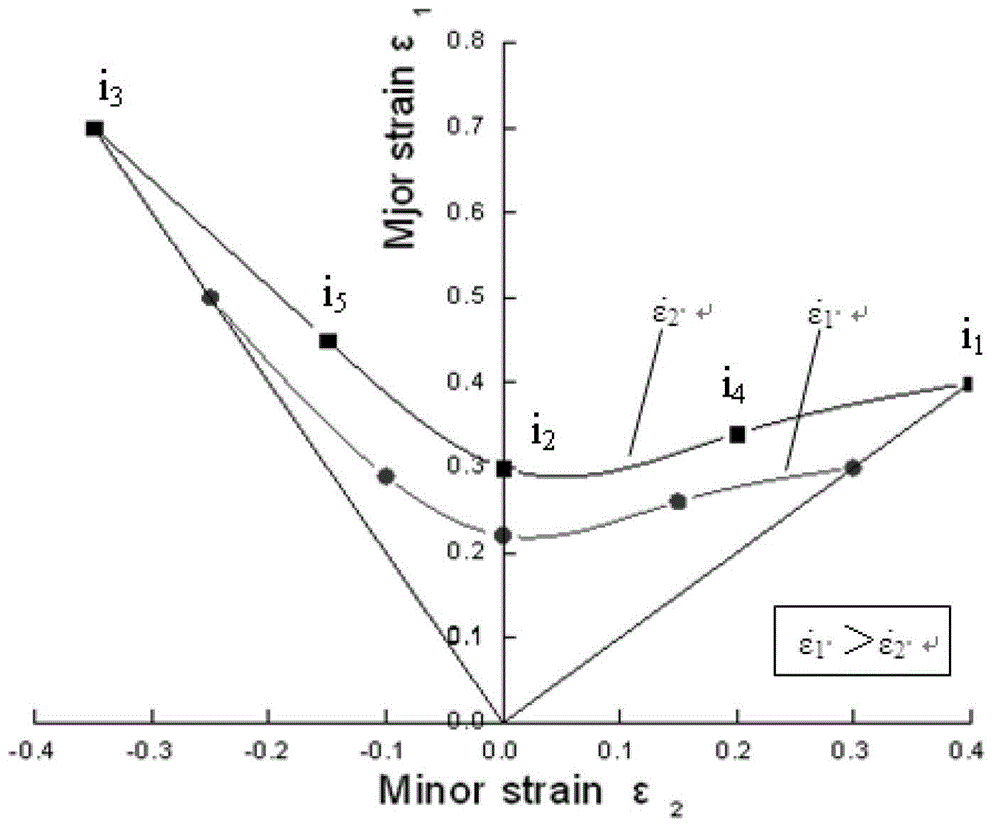

[0054] Such as figure 1 As shown, a test system of a plate high temperature forming limit diagram of the present invention includes: a material heat / force simulation test device 1, a biaxial tensile device 2 and a measurement and analysis device 3; a material heat / force simulation test device 1 and a biaxial The axial tension device 2 is connected; the material thermal / mechanical simulation test device 1 is used to control the temperature and strain rate of the deformation area of the sample; the biaxial tension device 2 is used to realize the tensile deformation of the sample in different strain states; the measurement and analysis device 3 is used to calculate the primary and secondary strains of the deformed sample by comparing the randomly distributed spot thresholds on the sample surface at different deformation moments after obtaining the entire deformation process of the sample, and then obtain the forming limit diagram of the sheet.

[0055]Wherein, the material ther...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com