Testing device and testing method for establishing high-temperature formed limit diagram of ultrahigh-strength boron steel plate

A test device, high temperature forming technology, applied in the direction of measuring device, strength characteristics, test material ductility, etc., can solve the problems of unable to test the forming limit of the sample, no heating and cooling control system, unable to control the temperature, etc. Avoid heat loss, ensure reliability, and uniform heating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

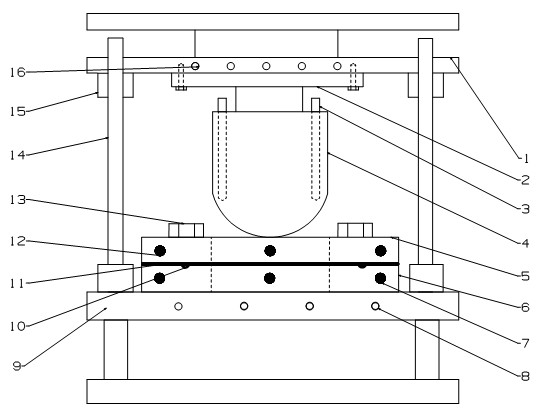

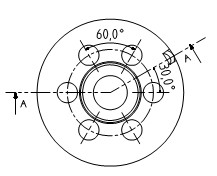

[0042] Such as Figure 1-5 所示,一种建立超高强硼钢板高温成形极限图的试验装置,包括上模架1和下模架9,所述下模架9上设有若干根导柱14,所述上模架1套于导柱14上,上模架1下表面上设有凸模装置,下模架9上设有与所述凸模装置相对应的上下叠放通过连接件固定在一起的压边圈5和凹模6;所述上模架1和下模架9上分别设有上模架冷却水道16和下模架冷却水道8;所述凸模4、凹模6和压边圈5内分别设有凸模加热器3、凹模加热器7和压边圈加热器12;所述凸模4内端部位置设有温度探针17。

[0043] 所述上模架1上设有使所述导柱14穿过的导套15。

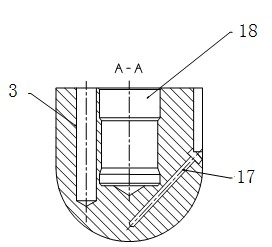

[0044] 所述凸模装置包括通过螺栓固定连接于上模架1下表面上的凸模固定板2,所述凸模固定板2下部通过拆卸式凸模固定装置18连接有端部呈半球形的凸模4。

[0045] 所述凸模固定装置18为台阶式结构体,其上端与所述凸模固定板2固定连接,下端固定于凸模4中心内部。

[0046] 所述连接件为内六角螺钉13。

[0047] 所述凹模6上表面上设有若干拉延筋10。

[0048] 所述各加热器均为柱形加热棒。

[0049] 本发明中的凹模6的设计与压边圈5结构类似。

[0050] 应用时,本发明中的温度探针17、各加热器、冷却水的运行以及凸模4的动作均通过控制系统实现,控制系统为现有的技术,在此不再赘述。

[0051] 超高强度钢板的高温胀形模具,在模具结构和功能要求上与传统的冷冲压模具有很大的区别:

[0052] (1)料定位要求快速准确。由于高温板料在空气中的暴露时间不宜过长,否则坯料温度下降过多,因此坯料必须能够在模具中迅速定位。

[0053] (2)模具材料须具有良好的热力学性能。高温坯料的热量部分将通过模具散失,势必造成模具温度升高,尤其表面温度上升剧烈。在如此恶劣的工作条件下,模具还须具有足够高的硬度能抵御与坯料发生热摩擦。

[0054] (3)模具须具有一定隔热能力,减少...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com