Method for establishing and using forming limit diagram of metal sheet material

A forming limit diagram, metal sheet technology, applied in the evaluation of the formability of magnesium (aluminum) alloy sheet in the heat treatment assisted forming process, the field of establishment of metal sheet forming limit diagram

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

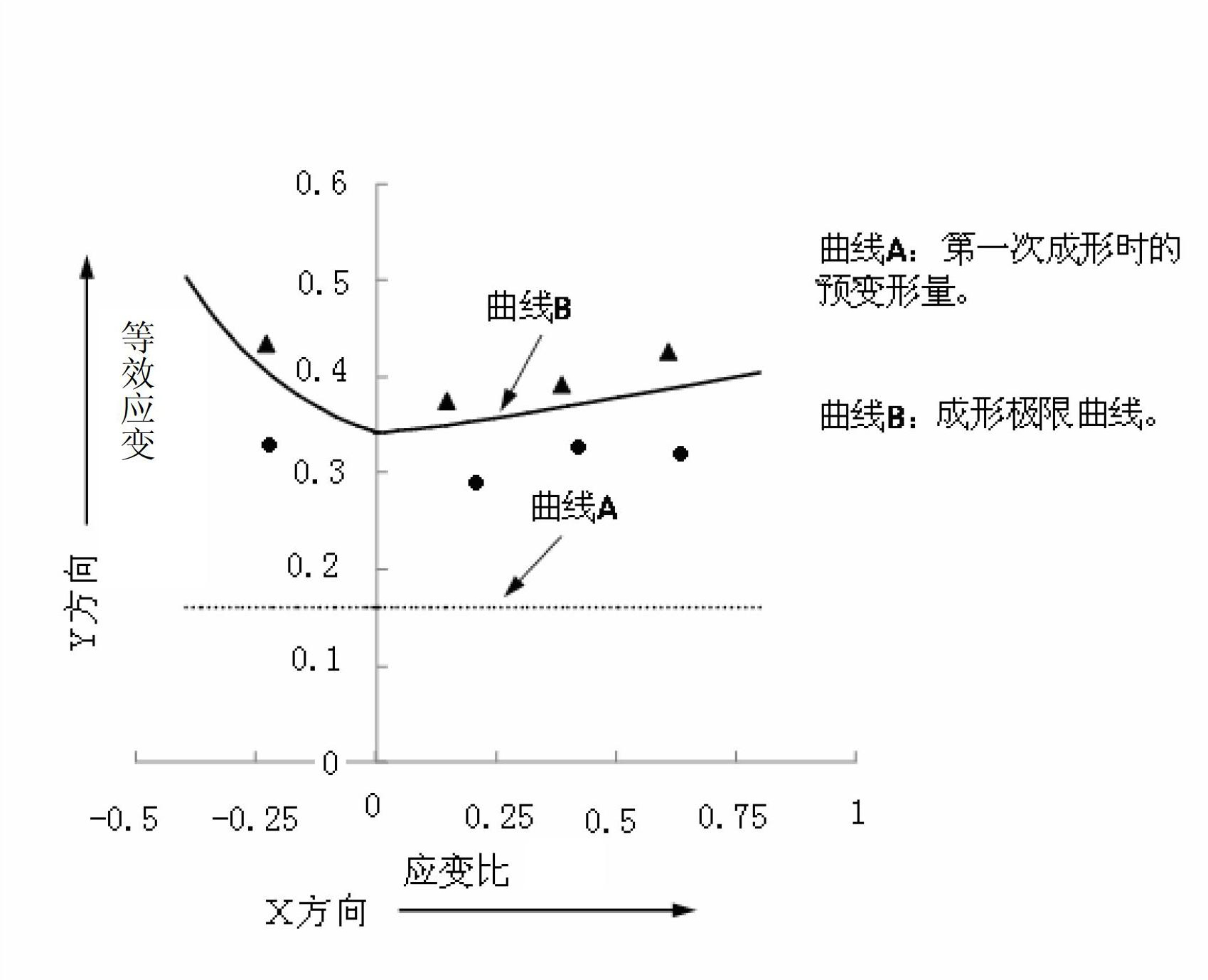

[0025] Firstly, the specific steps of the present invention to establish the sheet metal forming limit diagram are described.

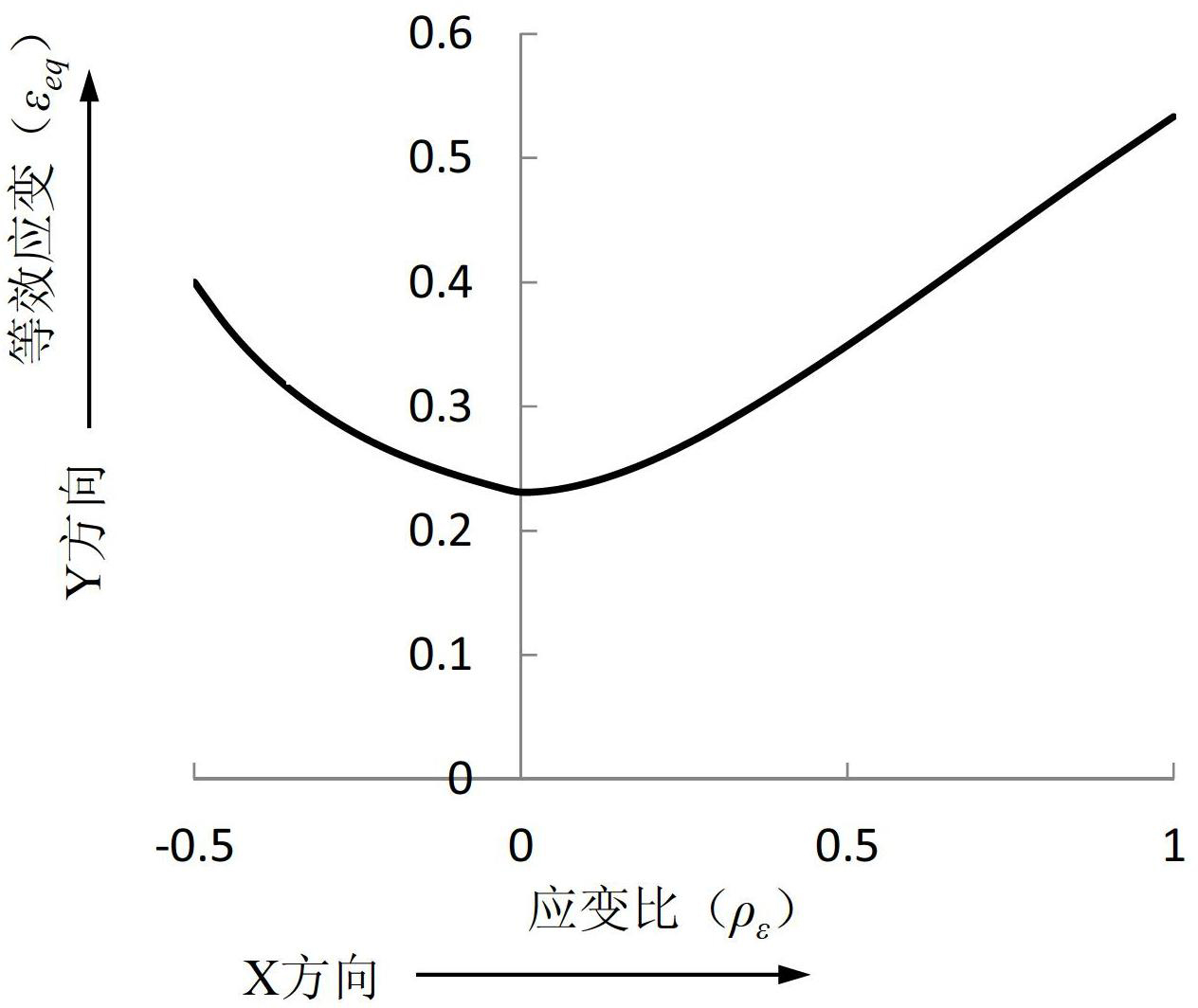

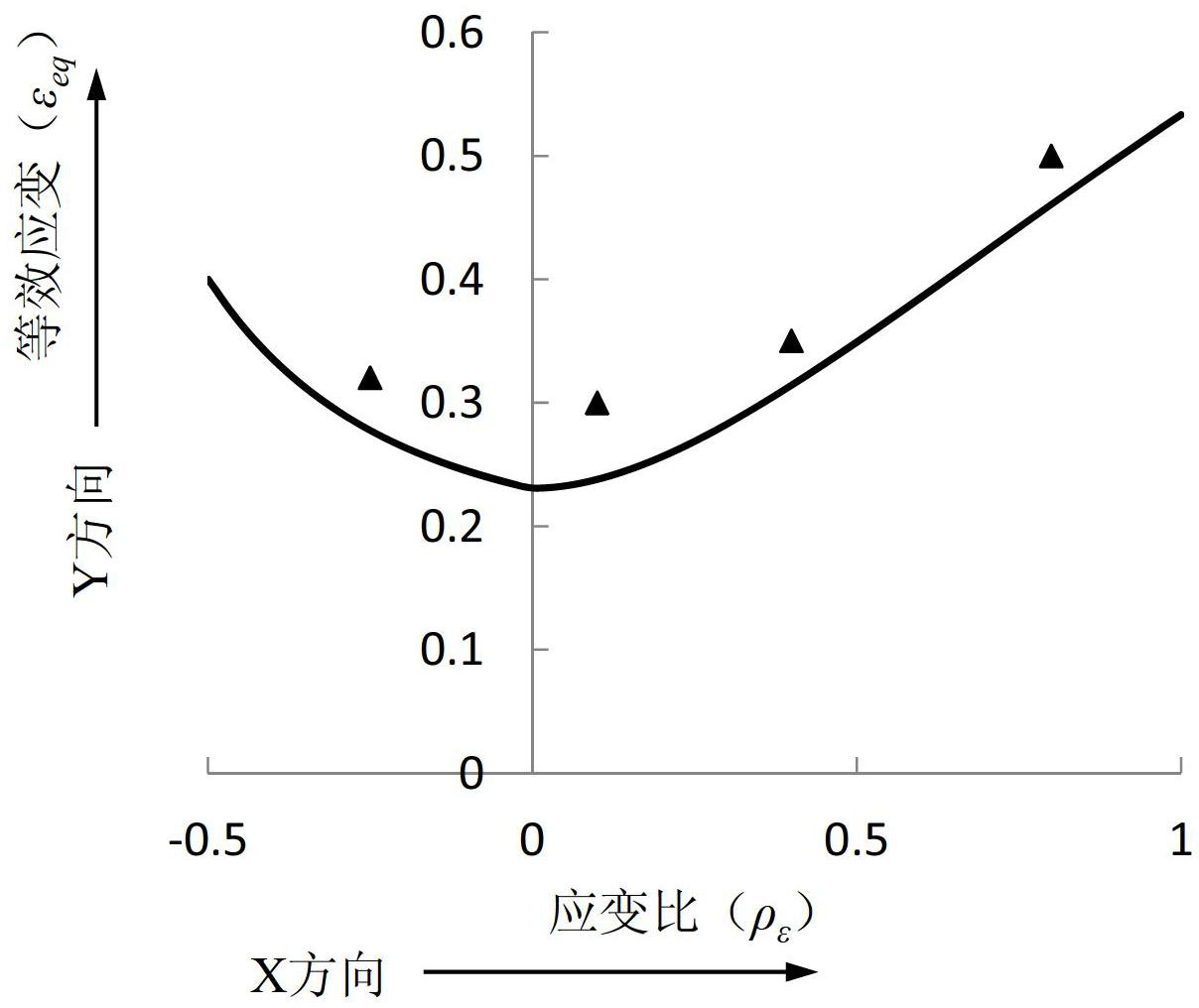

[0026] A. If figure 1 As shown, the XY coordinate system is established, and the X coordinate represents the strain ratio ρ ε , the Y coordinate represents the equivalent strain ε eq ;

[0027] B. Set the strain ratio ρ ε different values of , and calculate the corresponding principal strain ε according to different strain ratios 1 , and then calculate the corresponding secondary strain ε 2 , according to the strain formula launch ε 2 = ρ ε ε 1 get the secondary strain,

[0028] The principal strain ε 1 The specific calculation method is:

[0029] -0.5≤ρ ε ≤0, ϵ 1 = n 1 + ρ ϵ - - - ( 1 )

[003...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com