Test device for acquiring plate thermoforming limit diagram

A testing device and a technology of limit diagrams, which are applied in the field of testing devices for obtaining limit diagrams for sheet metal thermoforming, can solve the problem that there is no unified standard for judging instability behavior, the accurate acquisition of sheet metal thermoforming limit diagrams is complicated, and the failure of samples cannot be guaranteed. Steady state and other issues, to achieve the effect of small space occupation, large error overcoming, and convenient processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

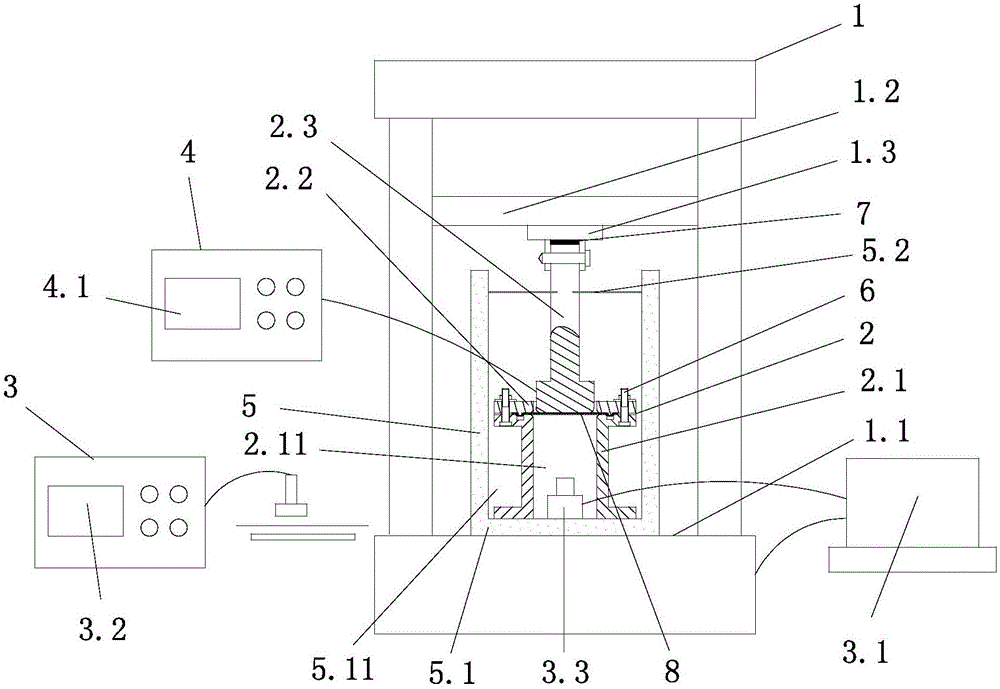

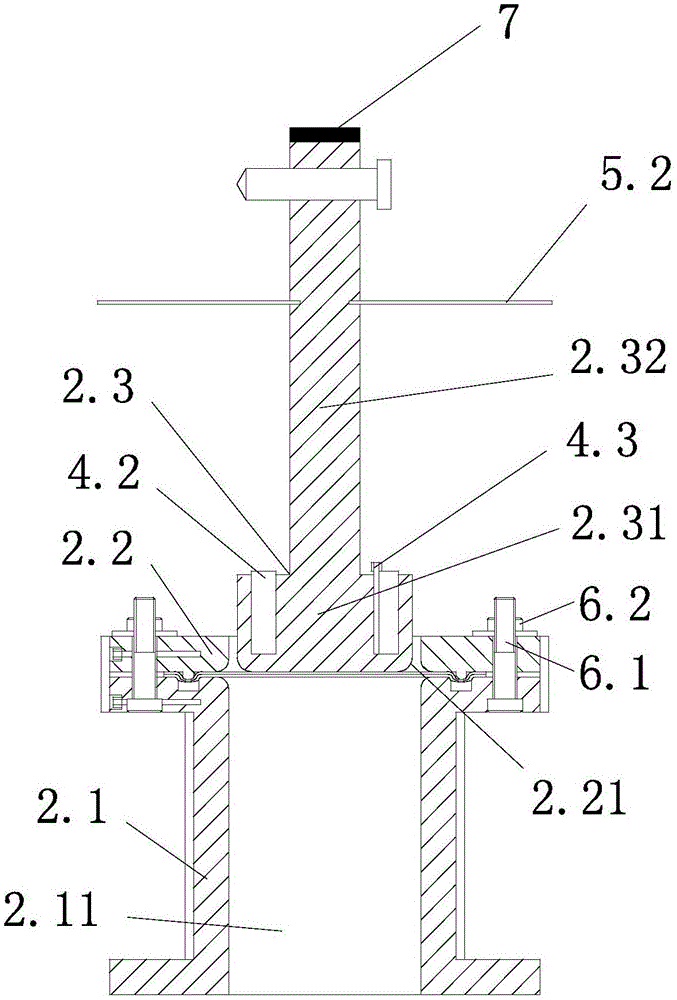

[0041] see Figure 1 to Figure 2 , a test device for obtaining a thermoforming limit diagram of a plate, including a universal testing machine 1, a mold 2, a strain measurement and analysis device 3, a heating control device 4, and a thermal insulation device 5.

[0042] The universal testing machine 1 includes a horizontally arranged worktable 1.1, a center beam 1.2 horizontally arranged directly above the worktable 1.1 and capable of moving up and down in the vertical direction, and a force sensor 1.3 connected below the center beam 1.2.

[0043] The heating control device 4 includes a temperature control device 4.1 and a heating component 4.2 and a temperature sensing component 4.3 respectively connected to the temperature control device 4.1, the heating component 4.2 adopts a heating rod or a heating strip, and the temperature sensing component 4.3 Use thermocouples, the temperature control device 4.1 uses a temperature controller, and the heating rod, heating strip and th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com