Automatic husking and screening device for rice

A screening device and automatic technology, applied in grain hulling, sieving, grain processing, etc., can solve the problems of screening, low rice yield, broken rice, etc., to improve the quality and appearance, improve the effect of shelling, The effect of reducing the stickiness of moisture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

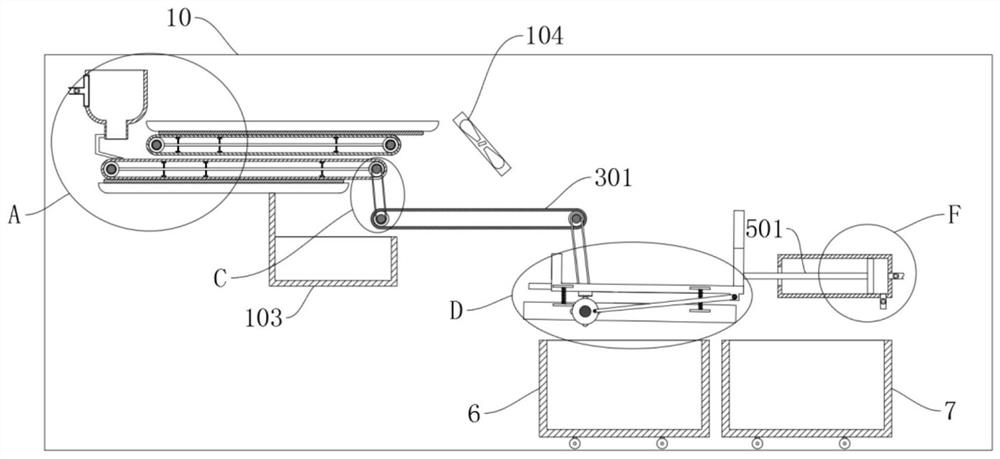

[0034] refer to Figure 1-11 , a paddy automatic shelling and screening device, including a frame 10, also includes: a shelling assembly, connected to the frame 10, for shelling the paddy; a motor 8, connected to the shelling assembly, for driving the shelling assembly Component work; fan 104, fixedly connected on the frame 10, is used to blow off the rice husk; transport component, connected on the frame 10, is used for transporting the rice grain after shelling and goes to the next procedure; wherein, the first belt 302, It is used to connect the shelling assembly and the transport assembly; the screening assembly is connected to the frame 10 and is used to screen the size of the rice grains after shelling; wherein, the second belt 9 is used to connect the transport assembly and the screening assembly ;

[0035] By placing the rice on the shelling assembly, the shelling assembly shells the rice, and then the shelling assembly transports the shelled rice to the next process,...

Embodiment 2

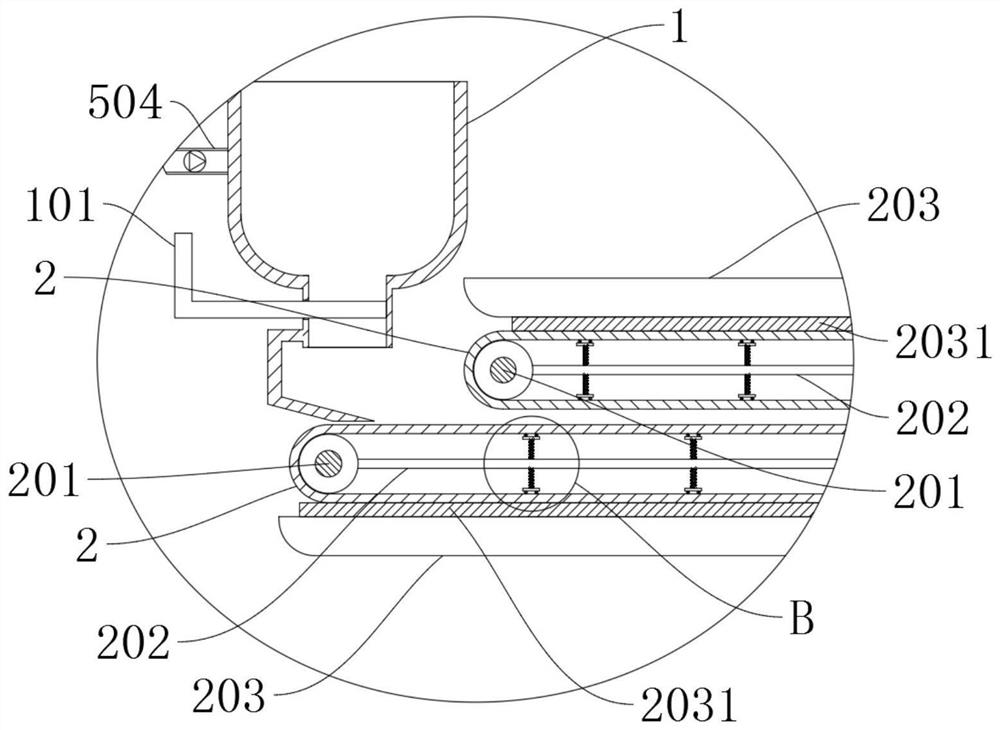

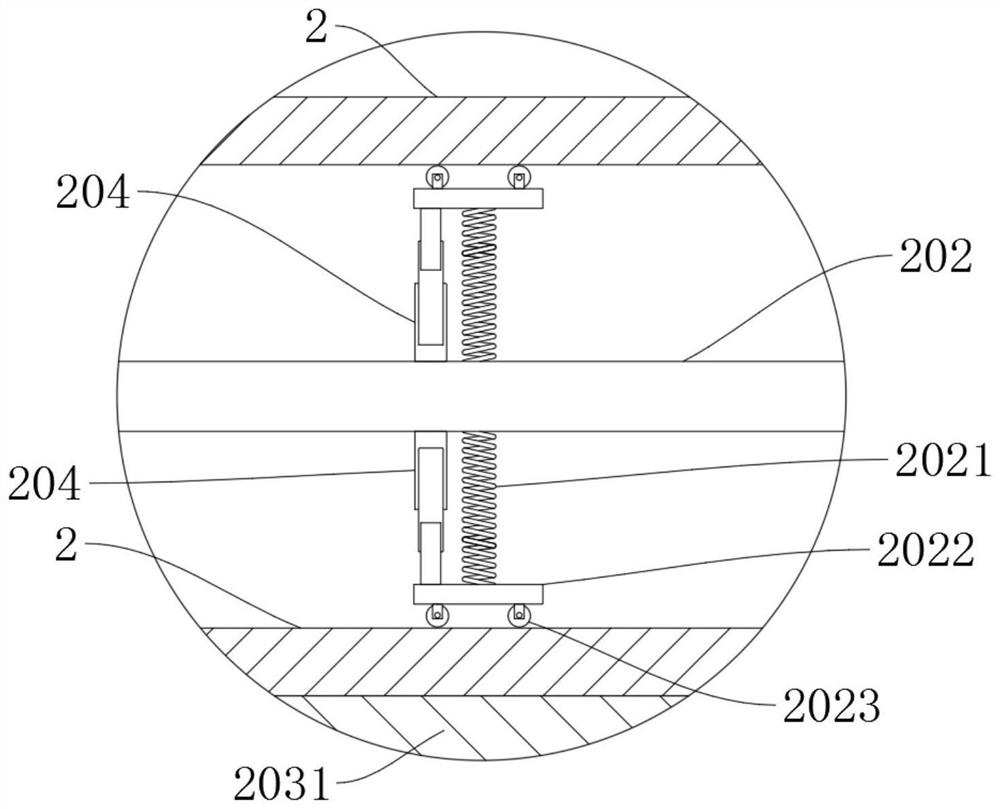

[0037] refer to Figure 1-11 , a paddy automatic shelling and screening device, which is basically the same as that of Embodiment 1, furthermore: the shelling assembly includes a first transmission assembly and a second transmission assembly, and the first transmission assembly and the second transmission assembly both include a first rotating shaft 201. The first transmission belt 2, the first rotating shaft 201 is symmetrically rotatably connected to the frame 10, the first transmission belt 2 is rotatably connected to two sets of first rotating shafts 201, the first transmission component and the second transmission component are in a vertical positional relationship, A small gear 801 is fixedly connected to the first rotating shaft 201 in the first transmission assembly, a large gear 802 is fixedly connected to the first rotating shaft 201 in the second transmission assembly, the small gear 801 and the large gear 802 are meshed, and the motor 8 is fixedly connected to the s...

Embodiment 3

[0041] refer to Figure 1-11 , a paddy automatic hulling and screening device, which is basically the same as that of Embodiment 1, furthermore: the transport assembly includes a second rotating shaft 3, a second transmission belt 301, and the second rotating shaft 3 is symmetrically connected to the frame 10, and the second The transmission belt 301 is rotatably connected to two sets of second rotating shafts 3, and the first belt 302 is connected to the first rotating shaft 201 and the second rotating shaft 3;

[0042] The first rotating shaft 201 on the first conveying assembly is connected with the second rotating shaft 3 by the first belt 302, when the first rotating shaft 201 rotates, the second rotating shaft 3 will be driven to rotate, and the hulled rice will fall from the first conveying assembly When falling on the second conveyor belt 301, the fan 104 blows off the rice husk, and then the rice grains drop onto the second conveyor belt 301 and are transported to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com