Evaluation method for hot stamping fracture property of automobile part

A technology for auto parts and evaluation methods, which is applied in the directions of strength characteristics, test material ductility, and material strength by applying stable tension/pressure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] In order to enable those skilled in the art to better understand the technical solution of the present application, the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0046] The orientation terms such as up, down, left, right, front and rear in this application document are established based on the positional relationship shown in the drawings. If the drawings are different, the corresponding positional relationship may also change accordingly, so this should not be understood as limiting the scope of protection.

[0047] The present invention will be described in detail below in conjunction with the accompanying drawings.

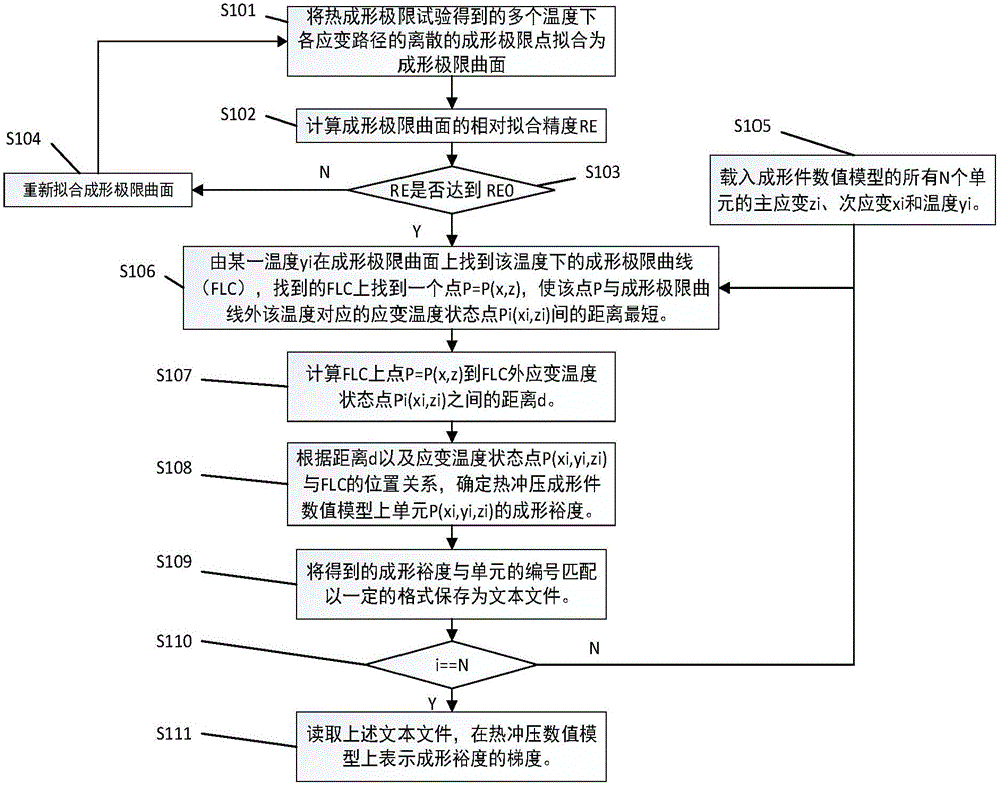

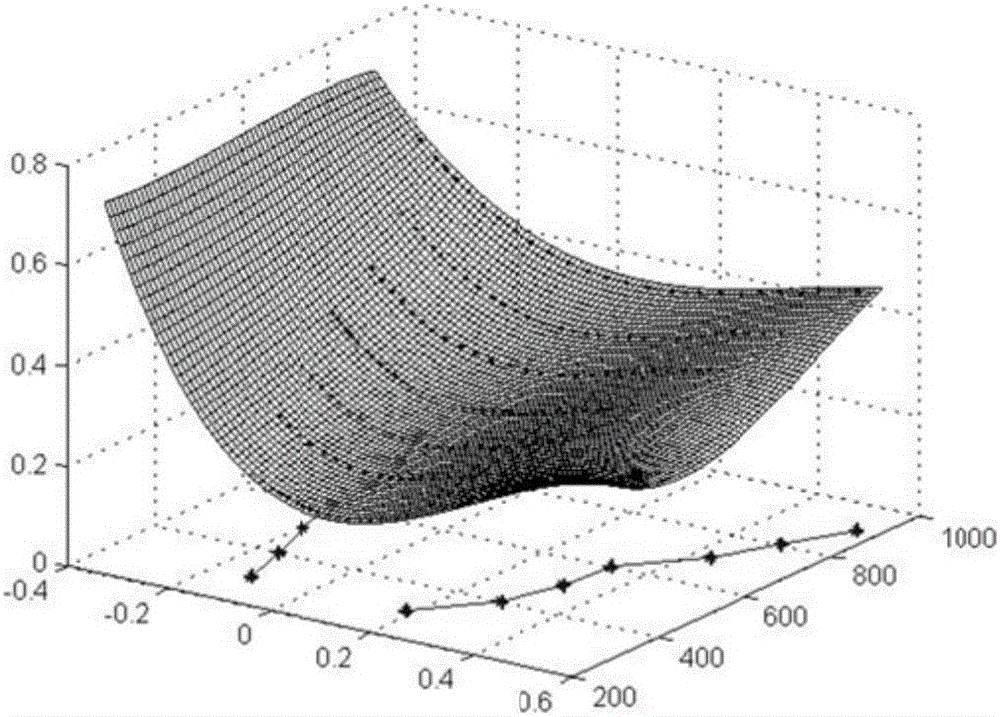

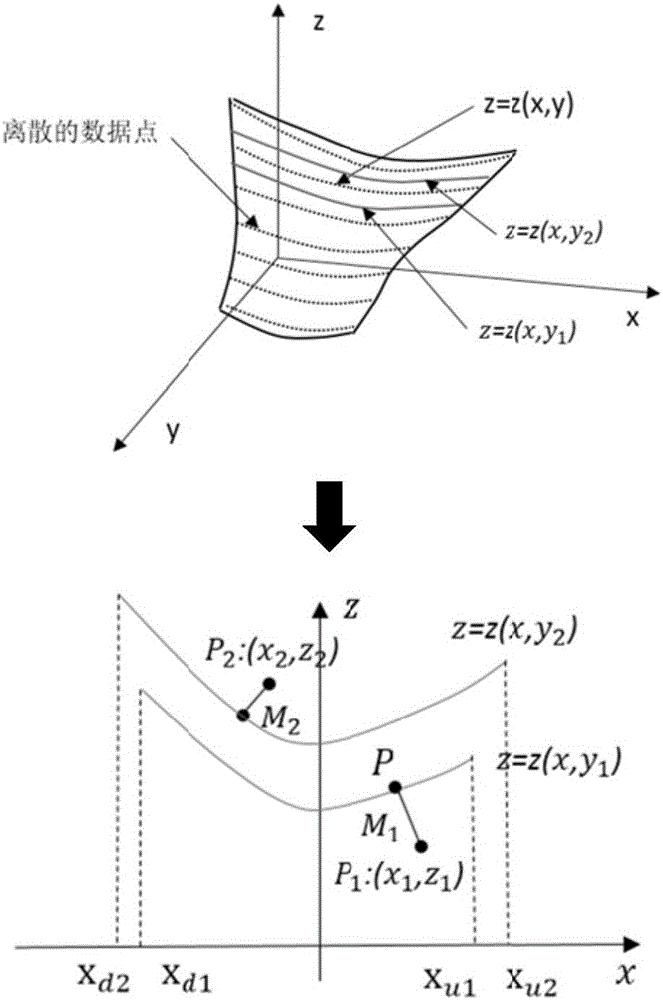

[0048] The invention provides a method for evaluating the hot stamping fracture performance of auto parts, which evaluates the quality of the hot stamping performance through the forming margin cloud chart and the forming limit chart corresponding to the same color gradient. Its implemen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com