Test and calculation method for measuring equivalent plastic strain forming limit diagram

A technique of equivalent plastic strain, forming limit diagram, applied in the direction of testing material strength, measuring device, strength characteristics, etc. using applied stable tension/compression

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

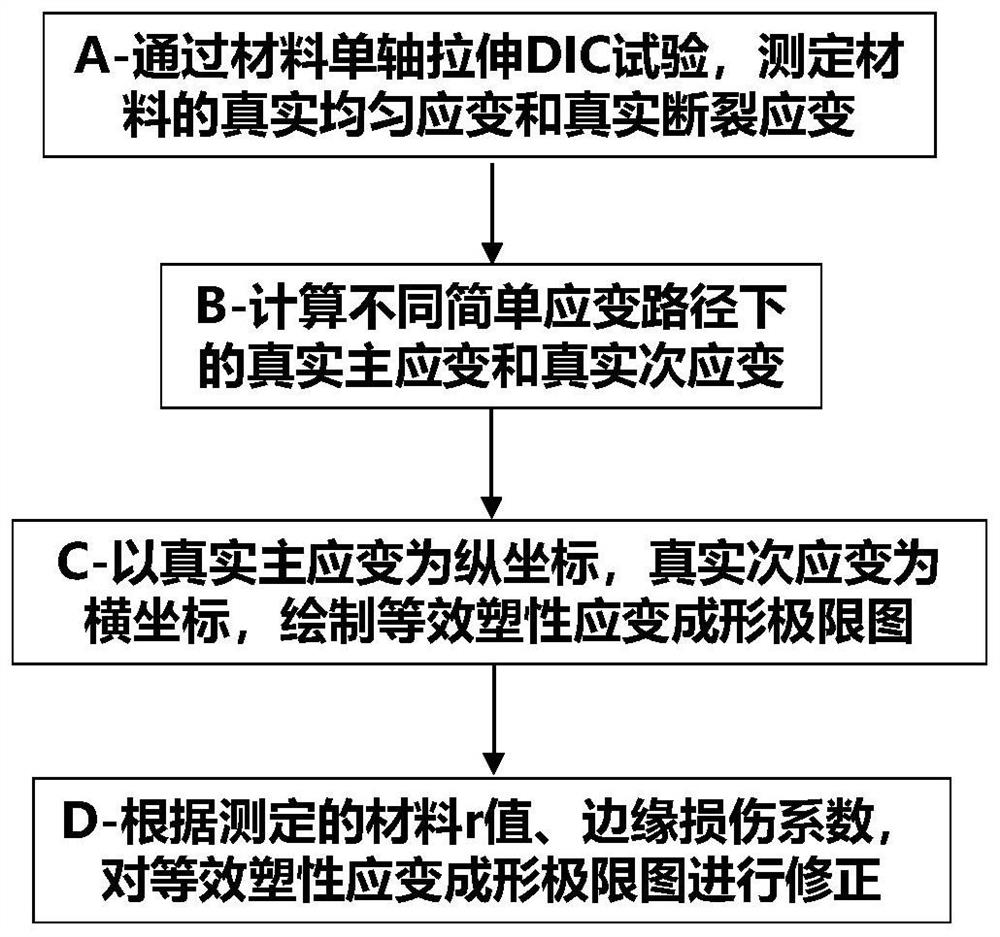

[0087] In this embodiment, with material DP780 / 1.4mm, the tensile testing machine model adopted is Zwick / Roell Z050, and the DIC test system is the ARAMIS system of German GOM Company, and describes in detail the determination of the material equivalent plastic strain forming limit diagram of the present invention. Experimental and computational methods, such as figure 1 As shown, it includes the following steps:

[0088] Step 1. Measure the true uniform strain (True Uniform Strain) of the tested material according to the method described in "A test and calculation method for measuring the true stress-strain curve of the material, application number 201910801077.1" and True Fracture Strain Uniaxial tensile tests were performed at quasi-static tensile rates.

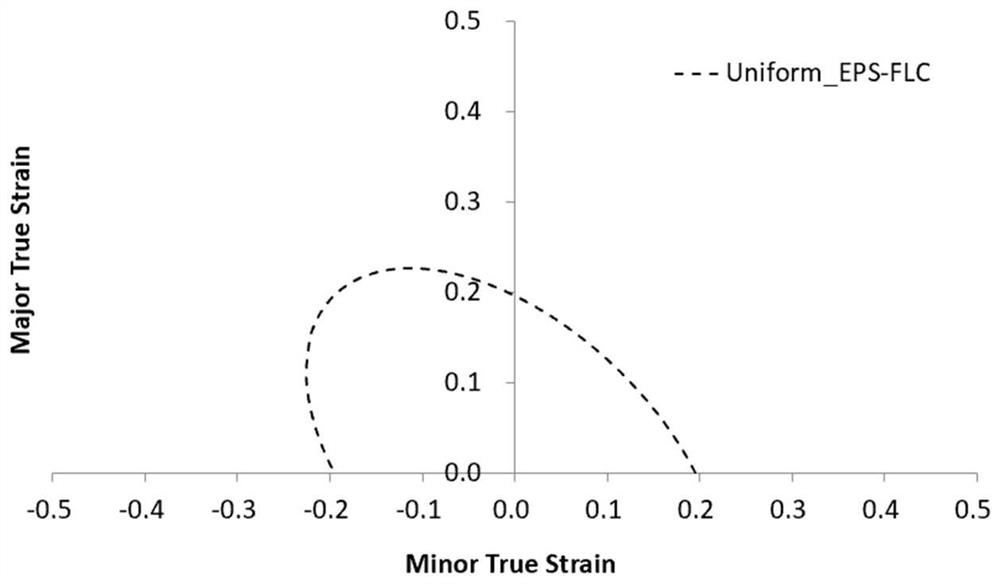

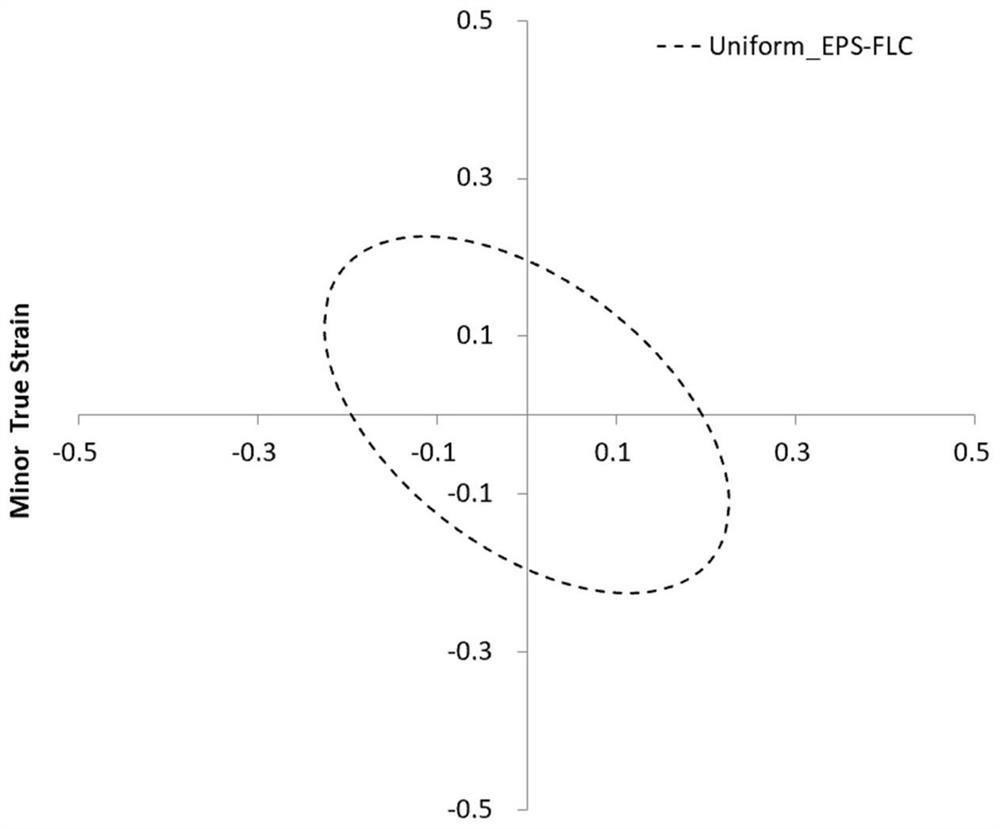

[0089]The true uniform strain It means: in the uniform necking deformation stage under the uniaxial tensile strain state, the finite body A with the initial length, width and height of 10mm·12mm·1.4mm remains unifor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com