Test device and method for acquiring forming limit diagrams under complicated loading condition

A technology of forming limit diagram and test device, which is applied in the direction of measuring device, testing material ductility, instrument, etc., can solve the problems of short interval, error-prone, complicated calculation process, etc., to save test time, shorten test cycle, Avoid the effects of the experimental process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

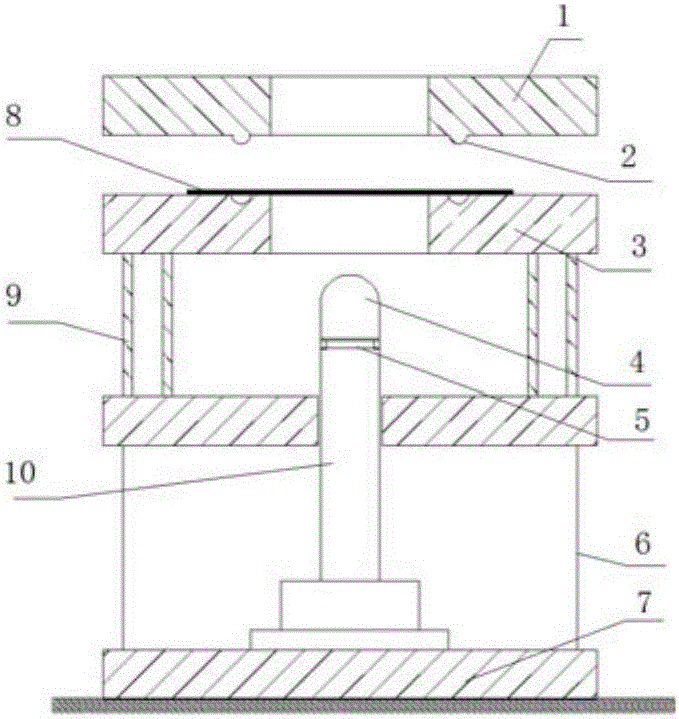

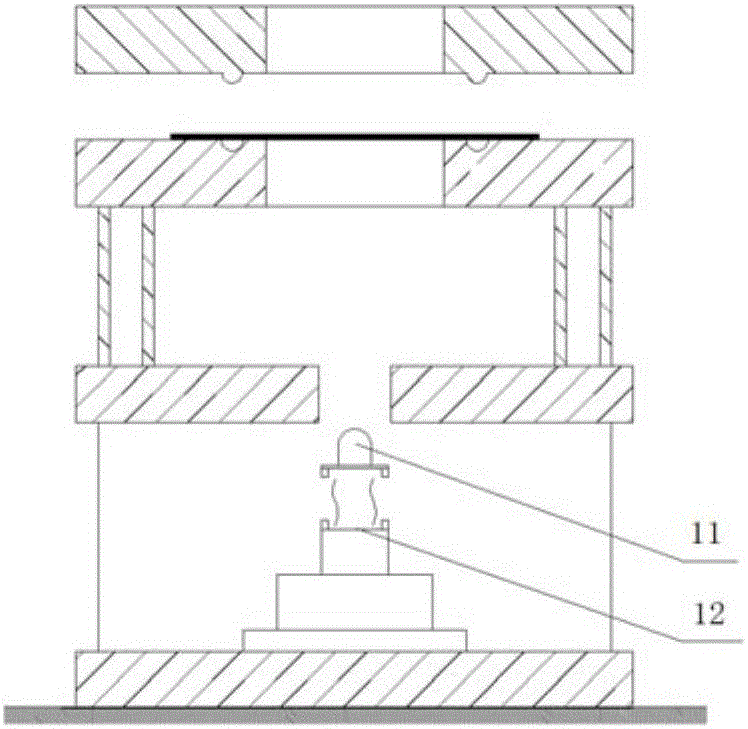

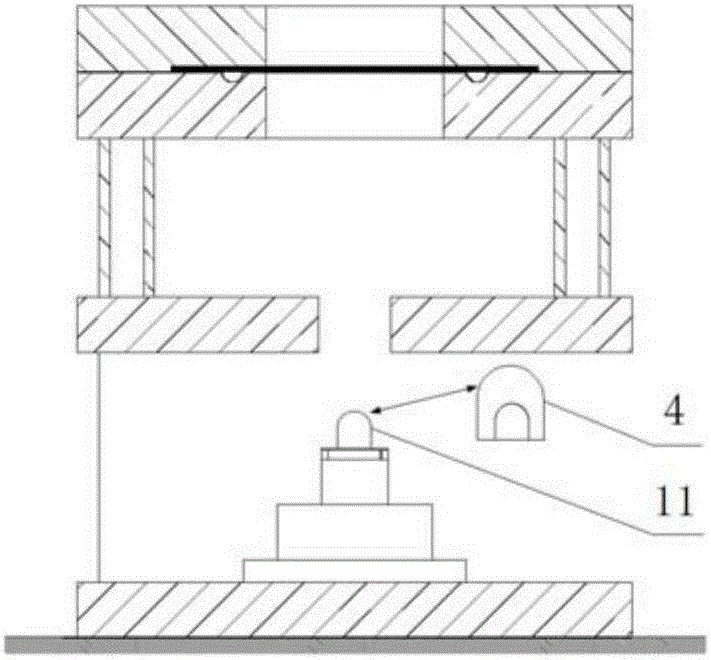

[0029] A test device for obtaining a forming limit diagram under complex loading conditions provided by the present invention includes a multifunctional sheet metal forming machine and a forming die; the multifunctional sheet material forming machine includes a forming machine base 7, a hydraulic ejector rod and a hydraulic control system; The mold includes a die 1 with a bead, a bezel 3 with a bead, a detachable outer plate 6 and a special punch; the special punch includes a small punch 11 and a large punch 4, and the small punch The upper end of 11 is a hemispherical punch, and the lower end of the small punch 11 is provided with a clamp interface 5, and the clamp interface 5 is used for docking with a vertically movable hydraulic ejector rod 10 connected to the punch. The punch 11 is a special mold for pre-deformation of the sheet; the inside of the big punch 4 is a cavity that can be socketed with the small punch 11, and the outside of the big punch 4 is a hemispherical pun...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com