Laser-propelling-based method and laser-propelling-based device for producing sheet shock forming limit diagram

A technology of impact forming and laser impact, which is applied in laser welding equipment, manufacturing tools, welding equipment, etc., can solve the problems of poor directionality of laser beam impacting sheet metal, high cost of mold making, long replacement time, etc., and achieves easy measurement Ultimate strain point, avoid excessive impact phenomenon, simple test process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Such as Figure 7 , 8 shown.

[0036] A method based on laser propulsion to make a limit diagram of sheet metal impact forming, including data collection and drawing of the limit diagram of sheet metal impact forming, which is characterized in that the shock wave generated by the repetition frequency pulse laser is used to propel the bullet, and the momentum generated by the bullet acts on different widths On the sheet, the bullet guide structure ensures the point and direction of the impact force, so that the deformation of the sheet is uniform and the data can be measured. The specific steps are as follows:

[0037] (1) Print a fine circular grid on the sheet;

[0038] (2) Cut the printed grid sheet into different widths;

[0039] (3) Put the above sheets on the die, the side without mesh is opposite to the bullet, and press it to death with a blank holder with calendering ribs;

[0040] (4) Fabricate propelling bullets, coat them with absorbing layers, and mount ...

Embodiment 2

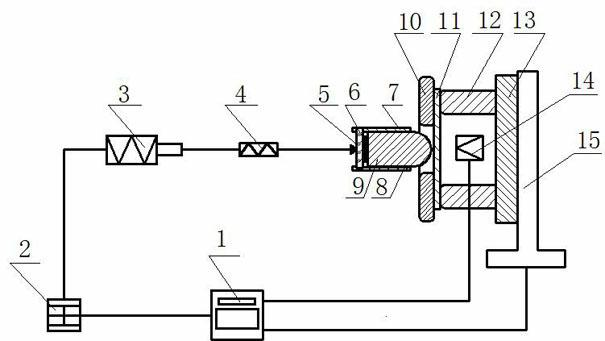

[0048] Such as Figure 1~8 shown.

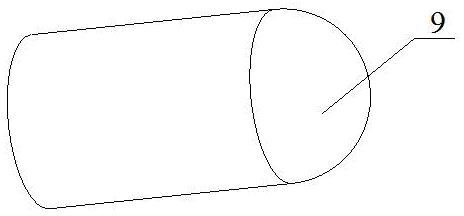

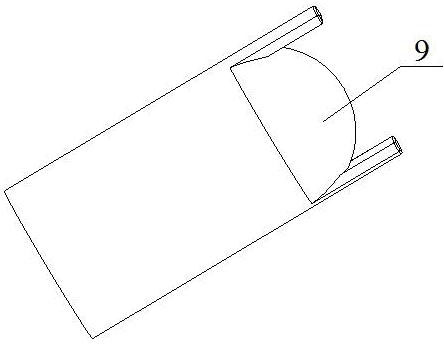

[0049] A device based on laser propulsion to produce sheet metal impact forming limit diagrams, which includes a central control processor 1, a laser controller 2, a repetition rate pulse laser 3, a spot adjustment device 4, glass 5, black paint coating 6, a bracket 7, 8. Bullet 9, blank holder 10, sheet material 11, die 12, multi-axis coordinate table 13, ultrasonic thermal imaging detector 14, coordinate axis rotation controller 15. It is characterized in that the central control processor 1 is electrically connected with the laser controller 2, the ultrasonic thermal imaging detector 14 and the coordinate axis rotation controller 15, the output of the laser controller 2 is connected with the input of the repetition frequency pulse laser 3, and the glass 5 is fixed on the On the brackets 7 and 8, bullets 9 covered with black paint coating 6 are put into the brackets 7 and 8 on the side facing the laser beam and close to the glass 5 to for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com