Chemico-mechanical polishing liquid and polishing method

A chemical mechanical and polishing liquid technology, which is applied in the direction of surface polishing machine tools, grinding/polishing equipment, polishing compositions containing abrasives, etc., can solve the problems of difficult control of material removal rate and surface quality, and influence of surface quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0079] A detailed description will be given below of specific embodiments of the present invention.

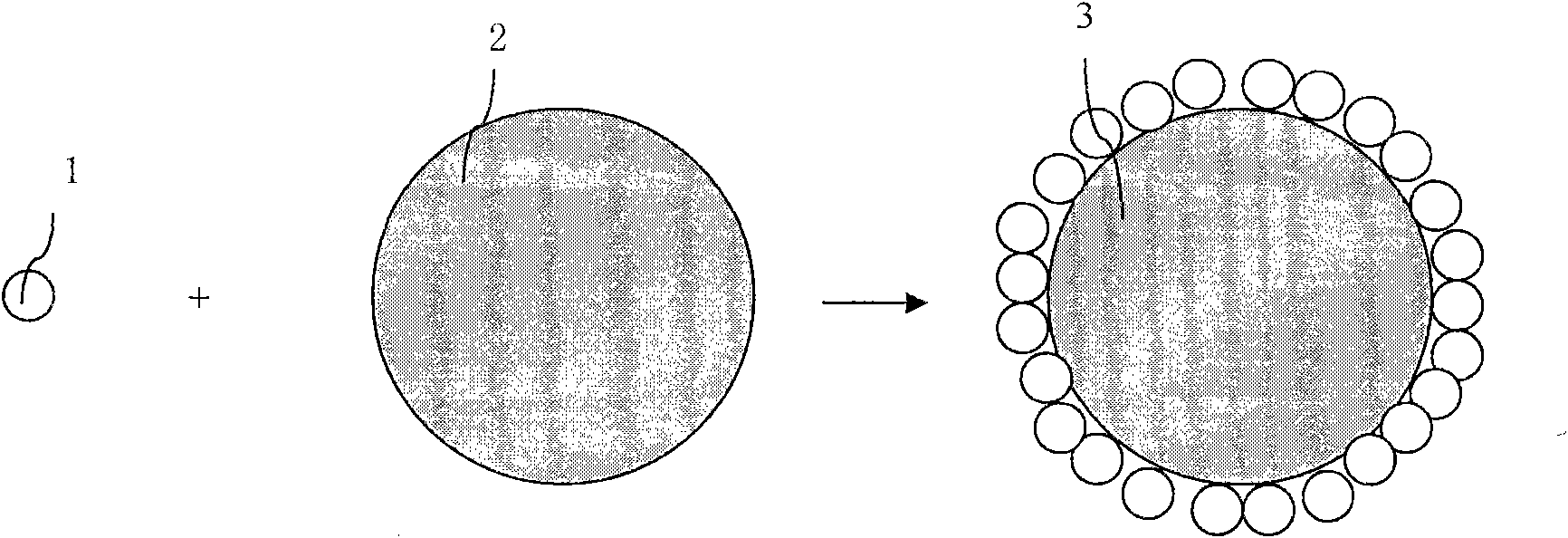

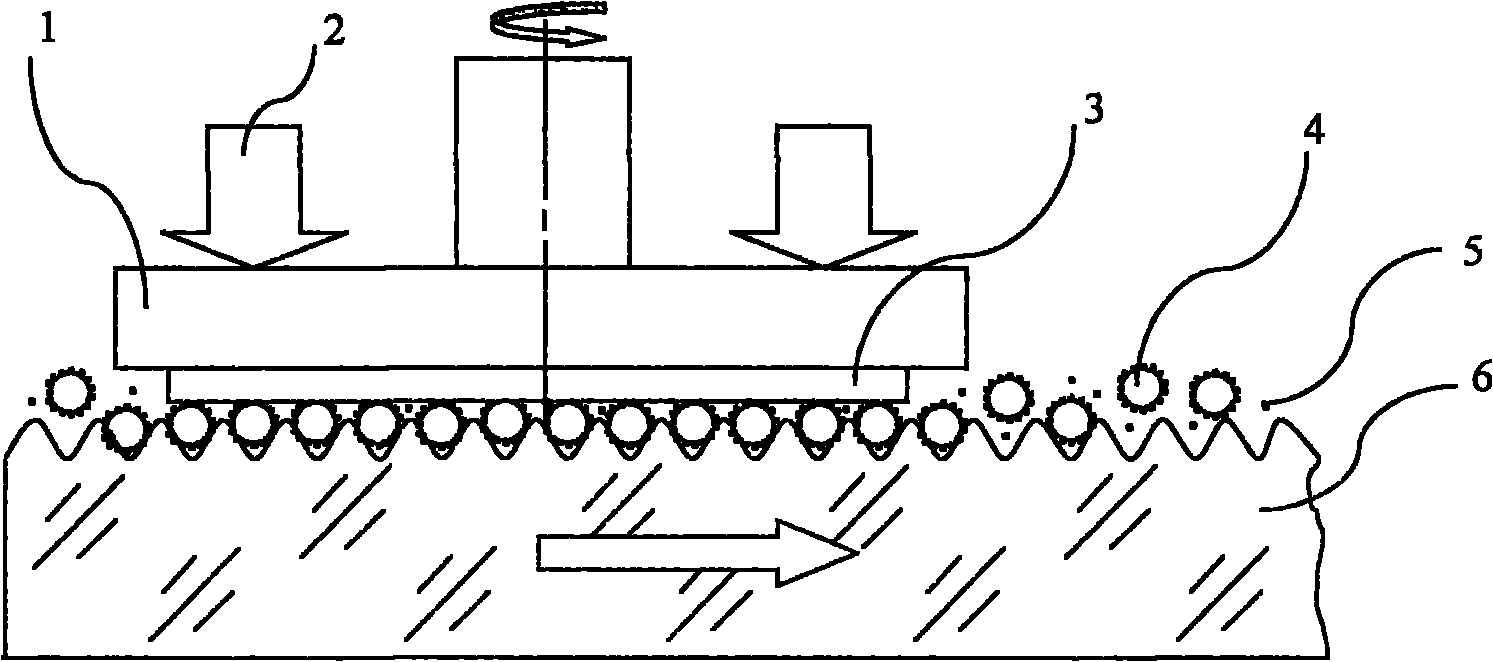

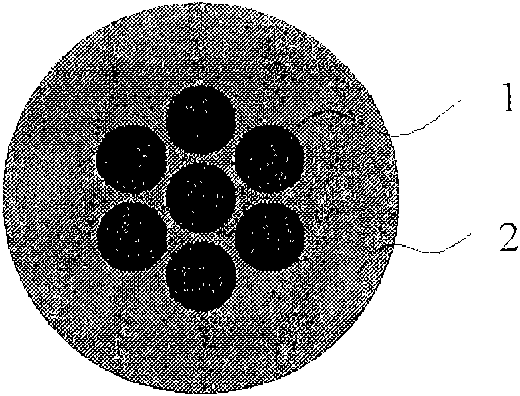

[0080] A chemical-mechanical polishing liquid, comprising a liquid in which composite abrasive grains are distributed, the composite abrasive grains are composed of large-grained magnetic polymer particles attached to the surface of small-diameter abrasives, and the magnetic polymer particles are magnetically wrapped by polymer materials. Material composition. The specific preparation of polishing fluid and comparison of polishing experiments are as follows:

[0081] 1. Preparation of magnetic particles and magnetic polymer particles

[0082] 1-1, Fe 3 o 4 Preparation of nanoparticles

[0083] 0.196 moles of FeCl 3 ·6H 2 O and 0.098 mol FeSO 4 ·6H 2O was placed in a 5000mL three-necked flask, and 2000mL of deionized water was added to dissolve, mechanically stirred, and high-purity argon gas was introduced to remove oxygen in the water. The argon atmosphere was heated ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com