Treatment method for improving surface pollution of LED chip

A technology for LED chips and surface pollution, which is applied in semiconductor devices, electrical components, circuits, etc., can solve the problems of abnormal surface of aluminum electrodes, susceptibility to acid and alkali corrosion, and difficult welding wires, etc., so as to improve product yield and avoid surface abnormalities , The effect of less raw material consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

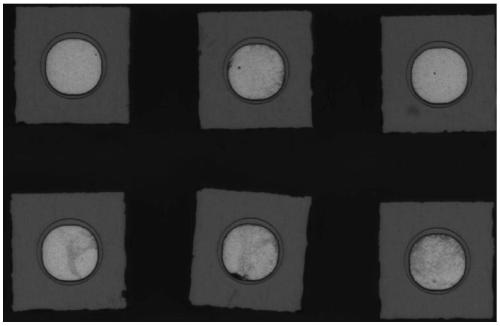

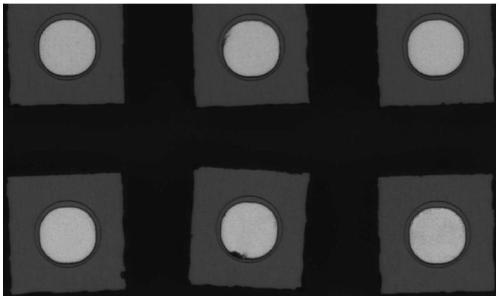

Image

Examples

Embodiment 1

[0031] A treatment method for improving surface pollution of LED chips, comprising the steps of:

[0032] (1) Clean the chip in an absolute ethanol solution with a purity of 99.7% for 15 seconds, then take it out and use a wool brush dipped in absolute ethanol to gently scrub the surface of the chip, scrub the entire chip surface 3 times, and then place the chip on Rinse under deionized water for 10s with a conductivity of 0.2μs / cm;

[0033] (2) Place the chip in an aqueous solution of 5% acetic acid (purity 99.6%) by volume and clean it for 3 minutes, then take it out and use a wool brush to dip the acetic acid aqueous solution to gently scrub the surface of the chip, scrub the entire chip surface 3 times, and then Rinse the chip under deionized water for 12s;

[0034] (3) Place the chip in a mixed solution composed of acetic acid (purity 96%), hypochlorous acid (purity 97%), ammonium fluoride (purity 97%), and deionized water (the weight ratio is 2% acetic acid, hypochlorou...

Embodiment 2

[0039] A treatment method for improving surface pollution of LED chips, comprising the steps of:

[0040] (1) Clean the chip in an absolute ethanol solution with a purity of 99.8% for 12 seconds, then take it out and use a wool brush dipped in absolute ethanol to gently scrub the surface of the chip, scrub the entire chip surface twice, and then place the chip on The conductivity is 0.18μs / cm and rinsed in deionized water for 14s;

[0041] (2) Place the chip in an aqueous solution of 3% acetic acid (99.7% purity) by volume and clean it for 4 minutes, then take it out and use a wool brush to dip in the acetic acid aqueous solution to gently scrub the surface of the chip, scrub the entire chip surface 4 times, and then Rinse the chip under deionized water for 20s;

[0042] (3) Place the chip in a mixed solution composed of oxalic acid (purity 99%), hydrogen sulfuric acid (purity 96%), sodium fluoride (purity 98%), and deionized water (the weight ratio is oxalic acid 6%, hydroge...

Embodiment 3

[0047] A treatment method for improving surface pollution of LED chips, comprising the steps of:

[0048] (1) Clean the chip in an absolute ethanol solution with a purity of 99.7% for 26 seconds, then take it out and use a wool brush dipped in absolute ethanol to gently scrub the surface of the chip, brush the entire chip surface 6 times, and then place the chip on The conductivity is 0.17μs / cm and rinsed under deionized water for 20s;

[0049] (2) Clean the chip in an aqueous solution of 8% acetic acid (99.8% purity) by volume for 2 minutes, then take it out and use a wool brush to dip in the aqueous solution of acetic acid to gently scrub the surface of the chip. The entire chip surface is scrubbed twice, and then Rinse the chip under deionized water for 21s;

[0050] (3) Place the chip in a mixed solution consisting of hypochlorous acid (purity 96%), hydrofluoric acid (purity 97%), ammonium fluoride (purity 95%), sodium bifluoride (purity 98%), and deionized water (The weig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com