Anti-condensation material as well as preparation method and application thereof

A technology of anti-condensation and porous materials, applied in application, separation method, prevention of condensed water, etc., can solve the problems of flocking cloth affecting the appearance, recycling restrictions, unfavorable condensation volatilization, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0035] On the other hand, an embodiment of the present invention provides a method for preparing the above-mentioned anti-condensation material, including:

[0036] The hydrophilic polymer material and the porogen are dissolved in a solvent to prepare a film casting liquid, the film is laid, and the porogen is removed to obtain the anti-condensation material.

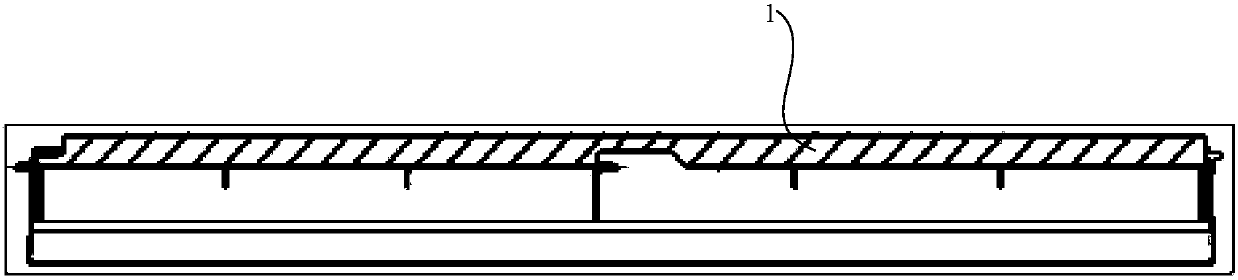

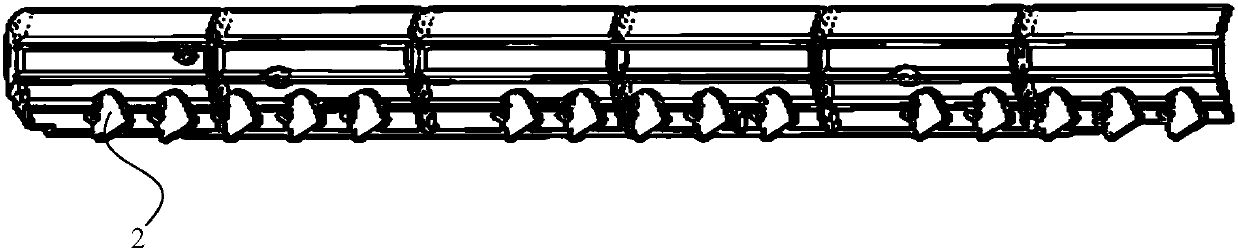

[0037] The embodiment of the present invention provides a method for preparing an anti-condensation material. The anti-condensation material is prepared by casting a film method. The obtained anti-condensation material is in the form of a membrane. The condensation material is pasted on the surface of the condensation occurrence site. Since the anti-condensation material is a porous film made of hydrophilic polymer material, the anti-condensation material has good water absorption and hydrophilic properties, and can replace the flocking cloth to absorb moisture in the air. Avoid the formation of condensation, so as to ...

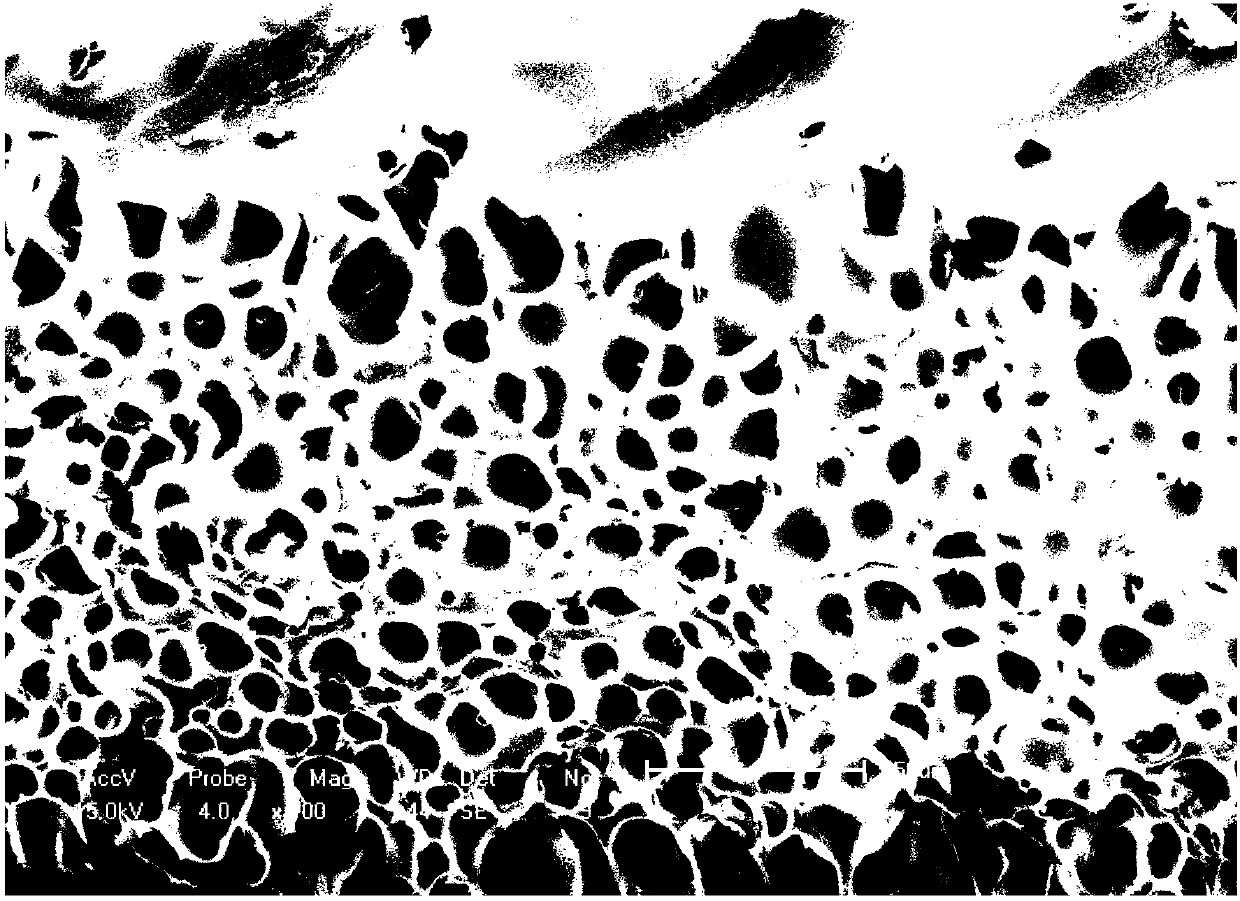

Embodiment 1

[0056] Dissolve the sulfonated polyethersulfone resin in N-methylpyrrolidone at a mass fraction of 10%, stir to obtain a transparent solution of sulfonated polyethersulfone, and dissolve a certain amount of β-cyclodextrin in a mass fraction of 95% % ethanol in aqueous solution, to obtain a β-cyclodextrin ethanol solution with a mass fraction of 60%, drop the β-cyclodextrin ethanol solution into the transparent solution of sulfonated polyethersulfone, and stir at room temperature for 12 hours Obtain a casting solution, wherein the mass ratio of the β-cyclodextrin to the sulfonated polyethersulfone resin is 50:100000;

[0057] Filter the casting solution and cast it on a horizontal glass surface, bake it in an oven at 60°C for 72 hours to obtain a flat film;

[0058] Continue to place the obtained flat film in a vacuum oven at 80°C to dry for 1 hour, then reflux the dried flat film in 95% methanol aqueous solution for 30 min, remove the β-cyclodextrin in the flat film, and fix ...

Embodiment 2

[0060] Dissolve the sulfonated polyethersulfone resin in N,N-dimethylacetamide at a mass fraction of 10%, stir to obtain a transparent solution of sulfonated polyethersulfone, and dissolve a certain amount of β-cyclodextrin in In an aqueous solution of ethanol with a mass fraction of 95%, an ethanol solution of β-cyclodextrin with a mass fraction of 60% is obtained, and the ethanol solution of β-cyclodextrin is added dropwise into the transparent solution of sulfonated polyethersulfone, at room temperature The casting solution was obtained after stirring for 10 hours, wherein the mass ratio of the β-cyclodextrin to the sulfonated polyethersulfone resin was 1:100000;

[0061] Filter the casting solution and cast it on a horizontal glass surface, bake it in an oven at 50°C for 48 hours to obtain a flat film;

[0062] Continue to place the obtained flat film in a vacuum oven at 80°C to dry for 3 hours, and then reflux the dried flat film in 95% methanol aqueous solution for 20 mi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average pore size | aaaaa | aaaaa |

| Average pore size | aaaaa | aaaaa |

| Average pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com