Grinding liquid reusing device and system thereof

A technology of grinding fluid and grinding process, applied in grinding/polishing equipment, metal processing equipment, manufacturing tools, etc., can solve the problems of inconvenient operation, affecting production capacity, waste of resources, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

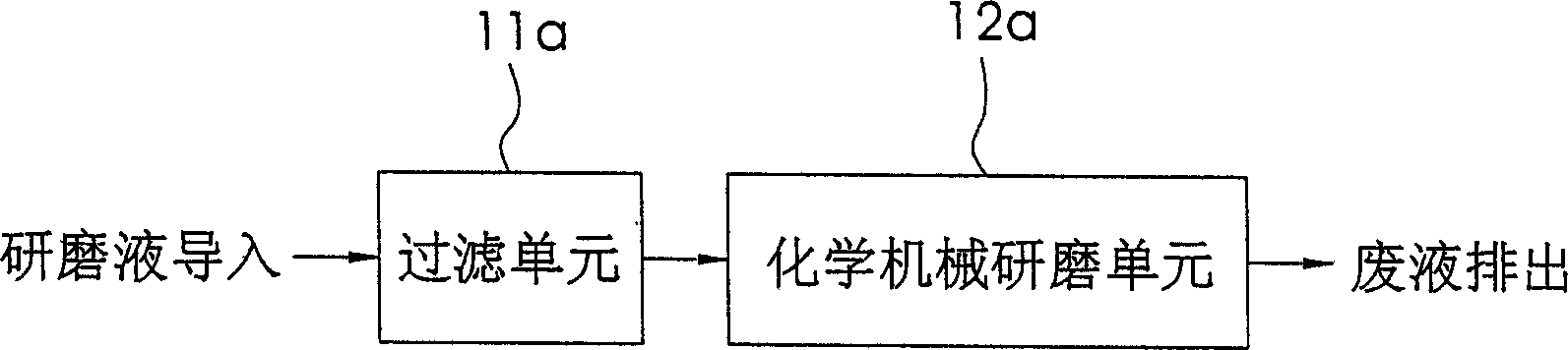

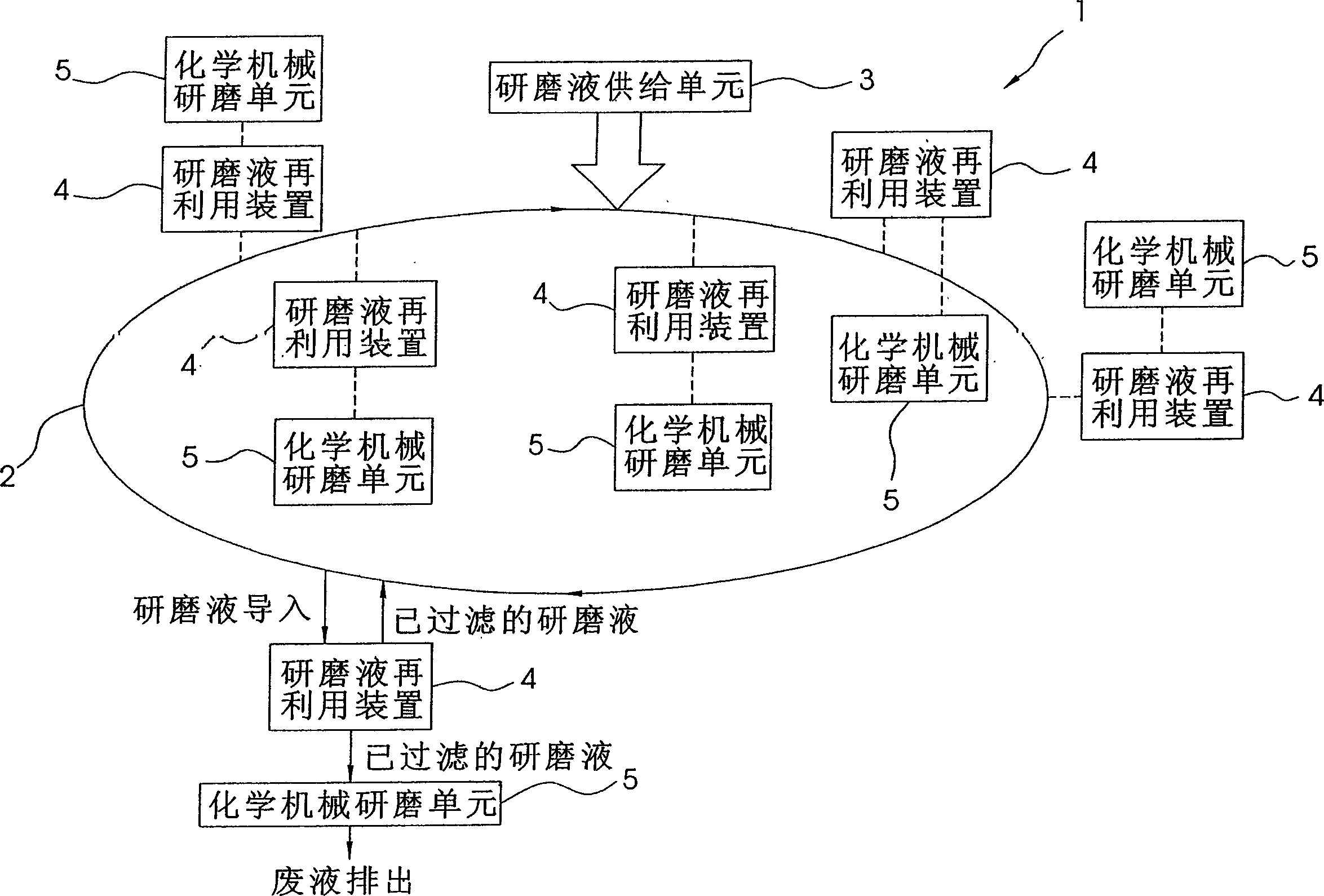

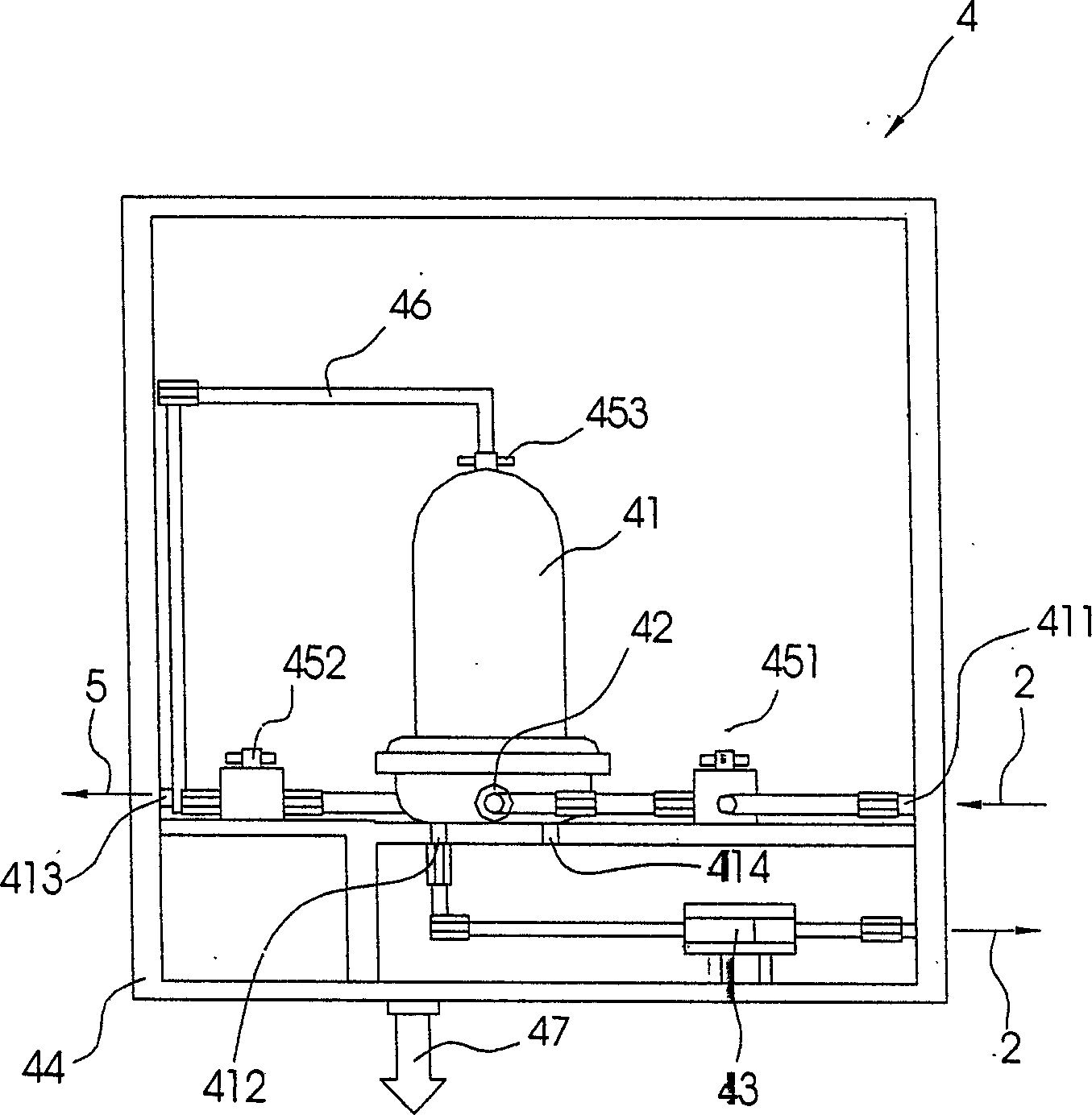

[0025] Please refer to figure 2 As shown, the present invention provides a polishing liquid recycling system 1 applied to a chemical mechanical polishing process. The system includes a polishing liquid circulation pipeline 2, at least one polishing liquid supply unit 3 connected to the polishing liquid circulation pipeline 2, and several A polishing liquid recycling device 4 connected to the polishing liquid circulation pipeline 2 and a plurality of chemical mechanical polishing units 5 respectively connected to the polishing liquid recycling device 4.

[0026] In the chemical mechanical polishing process of the present invention, the polishing liquid supply unit 3 is used to provide an abrasive slurry containing abrasive particles, and the slurry is injected into the polishing liquid circulation pipeline 2, and the polishing liquid can be transported at most through the polishing liquid circulation pipeline 2 One of the chemical mechanical grinding unit 5 (eg, chemical mechanica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com