Additive manufacturing device and additive manufacturing method

A technology for additive manufacturing, powder box

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

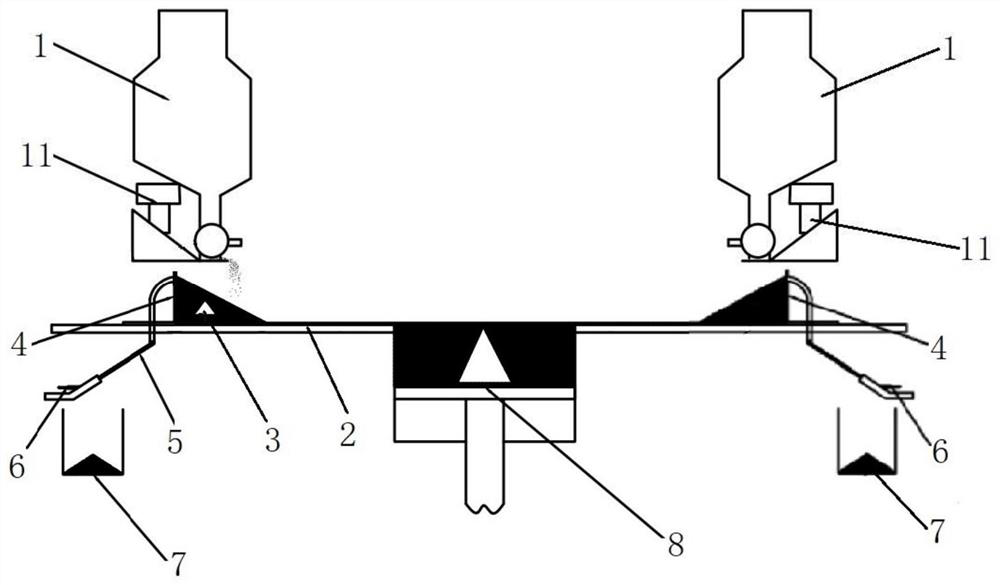

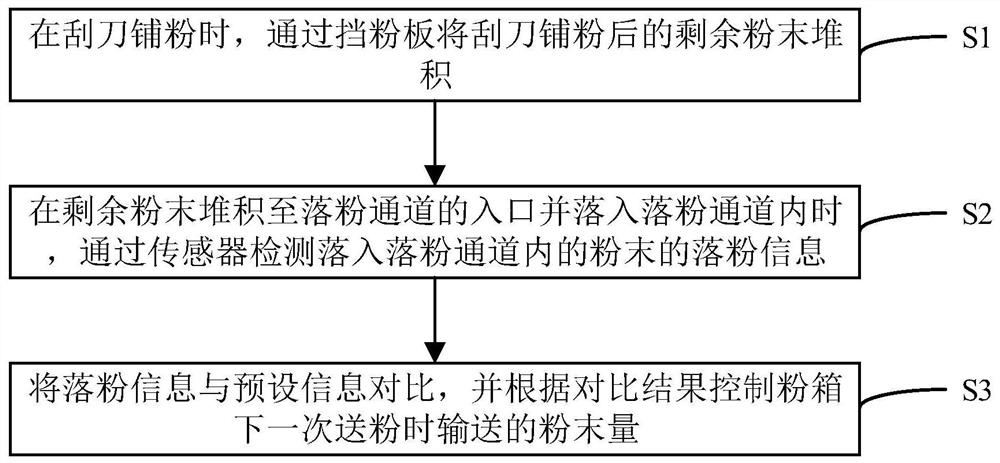

[0034] This embodiment provides an additive device, such as figure 1 As shown, the additive device includes a powder box 1, a powder spreading platform 2, a scraper 3, a powder baffle plate 4, a powder falling channel 5, a sensor 6, and a forming cylinder 8. The powder box 1, the powder spreading platform 2, and the scraper 3 , powder baffle plate 4, powder falling channel 5, sensor 6 and forming cylinder 8 are all placed in the forming chamber of vacuum to realize additive manufacturing. In this embodiment, the remaining powder is accumulated by setting the powder baffle plate 4, which can make the powder slope-shaped, and the powder falling channel 5 is set. When the remaining powder is piled up enough, the powder will enter the powder falling channel 5 and then pass through the sensor. 6. Detect the powder falling information of the falling powder (such as powder falling amount or powder falling time), and the amount of accumulated powder can be known according to the powde...

Embodiment 2

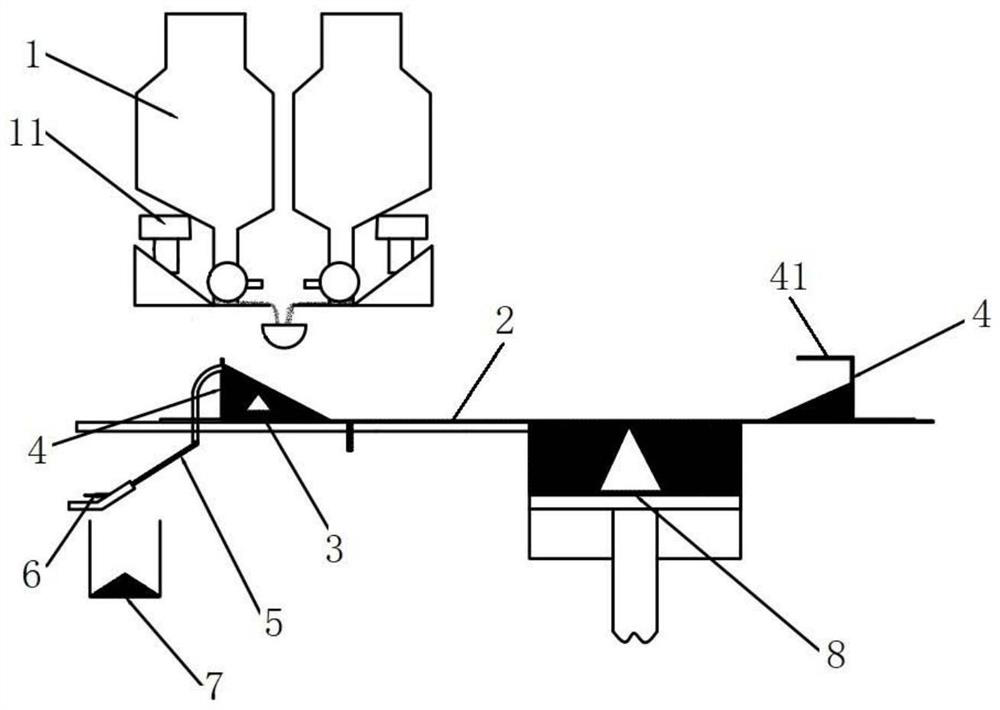

[0050] This embodiment provides an additive manufacturing device, which is different from Embodiment 1 in that the location of the powder falling channel 5 in this embodiment is different. Specifically, such as Figure 4 As shown, the powder falling channel 5 of this embodiment is set on the powder spreading platform 2 , and is specifically set on the side of the powder baffle plate 4 close to the forming cylinder 8 . There is a second through hole on the powder spreading platform 2, and the powder falling channel 5 is connected to the second through hole and placed under the powder spreading platform 2. When the remaining powder accumulates a lot, part of the remaining powder can fall through the second through hole. It enters the powder falling channel 5 and is detected by the sensor 6.

[0051] It can be understood that the powder box 1 of this embodiment can also be set to one or two according to needs, and when there are two powder boxes 1, the two powder boxes 1 can be ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com