Treatment method of epoxy resin production waste water

A treatment method and technology for producing waste water, applied in multi-stage water treatment, natural water body treatment, water treatment parameter control, etc., can solve problems such as waste of resources and increase in production capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

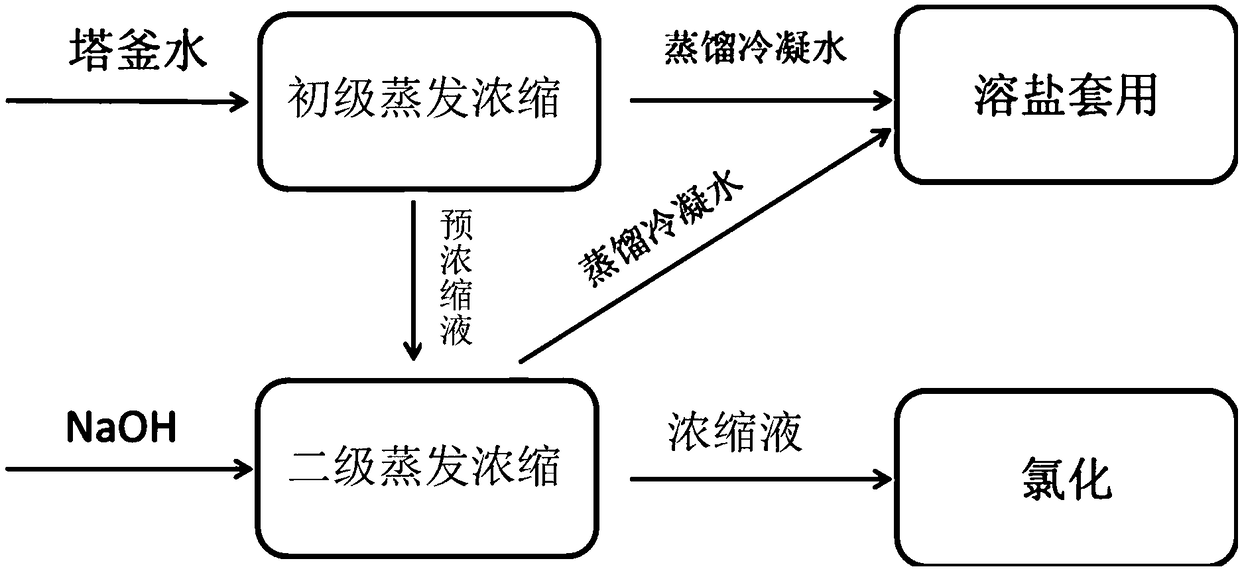

Method used

Image

Examples

Embodiment 1

[0036]A method for treating wastewater from epoxy resin production, comprising the following steps: subjecting COD18900ppm stripping tower kettle water to low-temperature and low-pressure evaporation concentration (primary evaporation concentration), pressure 50KPa, temperature 70°C, heat preservation for 120min; adding NaOH to adjust pH to neutral , the operating pressure of secondary evaporation and concentration is 4KPa, the temperature is 105°C, and the temperature is kept for 30 minutes. The main components of the concentrated solution obtained by final evaporation and concentration are: 79wt% of monochloropropanediol, 16wt% of glycerin, and 2.3wt% of water. Throw 1200g of concentrated solution into a four-necked flask, add 240g of glacial acetic acid as a catalyst, raise the temperature to 80°C, and continue to pass HCl gas at a rate of 15L / min, keep the temperature at 95°C for 16 hours, and concentrate after chlorination The quality content of dichloropropanol in the liq...

Embodiment 2

[0038] A method for treating waste water containing epichlorohydrin in the production process of epoxy resin, comprising the following steps: the COD is 19800ppm stripping tower kettle water through low temperature and low pressure evaporation concentration (primary evaporation concentration), operating pressure 70KPa, temperature 90 ℃, Insulate for 180 minutes; add NaOH to adjust the pH to neutral, the operating pressure of the second evaporation concentration is 5KPa, the temperature is 108°C, and keep warm for 25 minutes. The main components of the final concentrated solution are: 80wt% monochloropropanediol, 15wt% glycerin, and 2.5wt% water %. Throw 1300g of concentrated solution into a four-necked flask, add 250g of glacial acetic acid as a catalyst, raise the temperature to 80°C, pass HCl gas at a rate of 17L / min for hydrogen chloride gas, and keep the temperature at 100°C for 8 hours. The mass content of dichloropropanol in the concentrated solution after chlorination i...

Embodiment 3

[0040] A method for treating waste water containing epichlorohydrin in the epoxy resin production process, comprising the following steps: the COD is 21100ppm stripping tower kettle water through low temperature and low pressure evaporation concentration (primary evaporation concentration), operating pressure 90KPa, temperature 90 ℃, Insulate for 300 minutes; add NaOH to adjust the pH to neutral, the second evaporation concentrates the operating pressure at 6KPa, the final concentration temperature is 110°C, and maintains the temperature for 20 minutes to adjust the pH to neutral. The main components of the obtained concentrated solution are: monochloropropanediol 82wt%, glycerin 14wt%, water 2.8wt%. Throw 1350g of concentrated solution into a four-necked flask, add 280g of glacial acetic acid as a catalyst, heat up to 80°C, pass HCl gas at a rate of 18L / min, keep the temperature at 105°C for 6 hours, and the concentrated solution after chlorination The quality content of dich...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com