Phosphorous slag autoclave aerated concrete building block and preparation method thereof

A concrete block, autoclaved and aerated technology, which is applied to clay preparation devices, chemical instruments and methods, ceramic products, etc., can solve problems such as environmental pollution, phosphorus waste slag occupying space, resource waste, etc., and achieve the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0012] Example 1: Phosphorus slag 38kg, silica sand 17kg, quicklime 33kg, cement 7kg, gypsum 5kg, aluminum powder 0.15kg, sodium hydroxide 0.2kg, water 50kg

[0013] Mix phosphorus slag, silica sand, gypsum and water, ball mill, and make a mortar with a fineness of 0.08mm square hole sieve with 27% to 30% remaining and a specific gravity of 1.7 to 1.75Kg / L for later use; another quicklime, crushed and dry-processed Grind into a 0.08mm square hole sieve and sieve the remaining 25% to 30% quicklime powder, mix the mortar, quicklime powder, sodium hydroxide and cement, stir, add aluminum powder when the temperature reaches 35°C, stir evenly, pour, After statically stopping in a hot room at 60°C for 3 hours, it is demoulded and cut, and it is ready after 7 hours of autoclaving at 1.3Mpa.

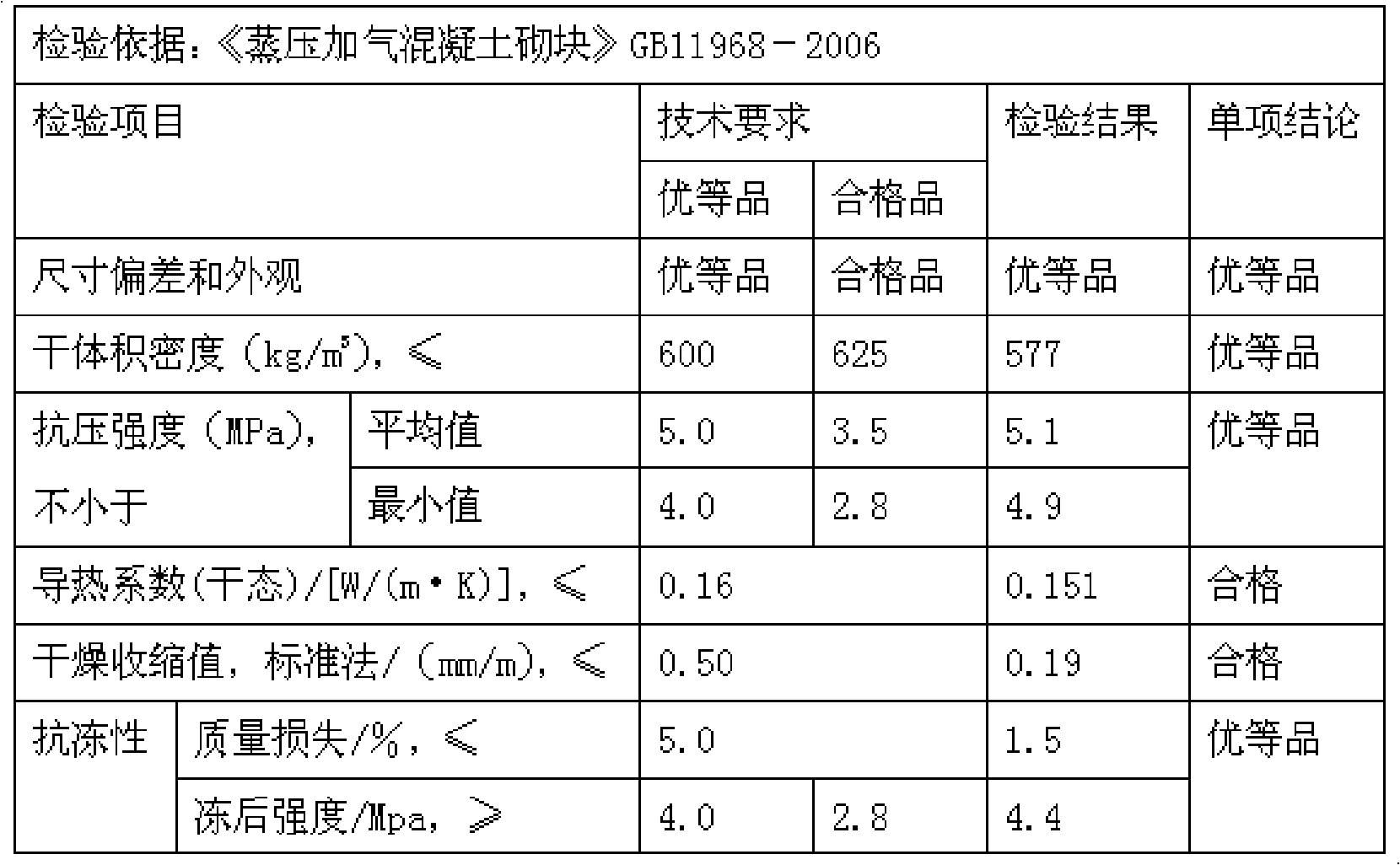

[0014] The above-mentioned autoclaved aerated concrete blocks were tested for performance, and the results are shown in the table below:

[0015]

[0016] The heat transfer coefficient, ther...

Embodiment 2

[0017] Embodiment 2: Phosphorus slag 764.75Kg, silica sand 342.125Kg, gypsum 100.625Kg, water 1006.25Kg are ball milled into slurry, get 2213.75Kg slurry, lime 644.125Kg, cement 140.875Kg, sodium carbonate 3Kg, aluminum powder 2.45Kg and stir into slurry pouring in For a mold with a volume of 3.5 cubic meters, stop in a hot chamber at 60-70°C for 5 hours, then remove the mold and cut it, put it into an autoclave and steam it in 1.2-1.35Mpa steam for 8 hours to get the finished product.

Embodiment 3

[0018] Example 3: Phosphorus slag 30kg, silica sand 20kg, quicklime 35kg, cement 5kg, gypsum 6kg, aluminum powder 0.1kg, water 50kg

[0019] Mix phosphorous slag, silica sand, gypsum and water, and grind them finely with a ball mill to make mortar; crush quicklime, dry grind, then mix mortar, quicklime powder, and cement, stir, and the quicklime reacts with water to release heat to the temperature Add aluminum powder when it reaches 30°C, stir evenly, pour according to the conventional method, stop the hot room, cut, and autoclave for curing.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Heat transfer coefficient | aaaaa | aaaaa |

| Thermal resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com