Heavy oil deep processing method and device

A technology for deep processing and heavy oil, applied in the field of heavy oil deep processing methods and devices, can solve the problems of easy cracking of high-temperature catalysts, low gasoline and diesel content, large sewage discharge, etc., to improve product distribution, reduce sewage discharge, and facilitate operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

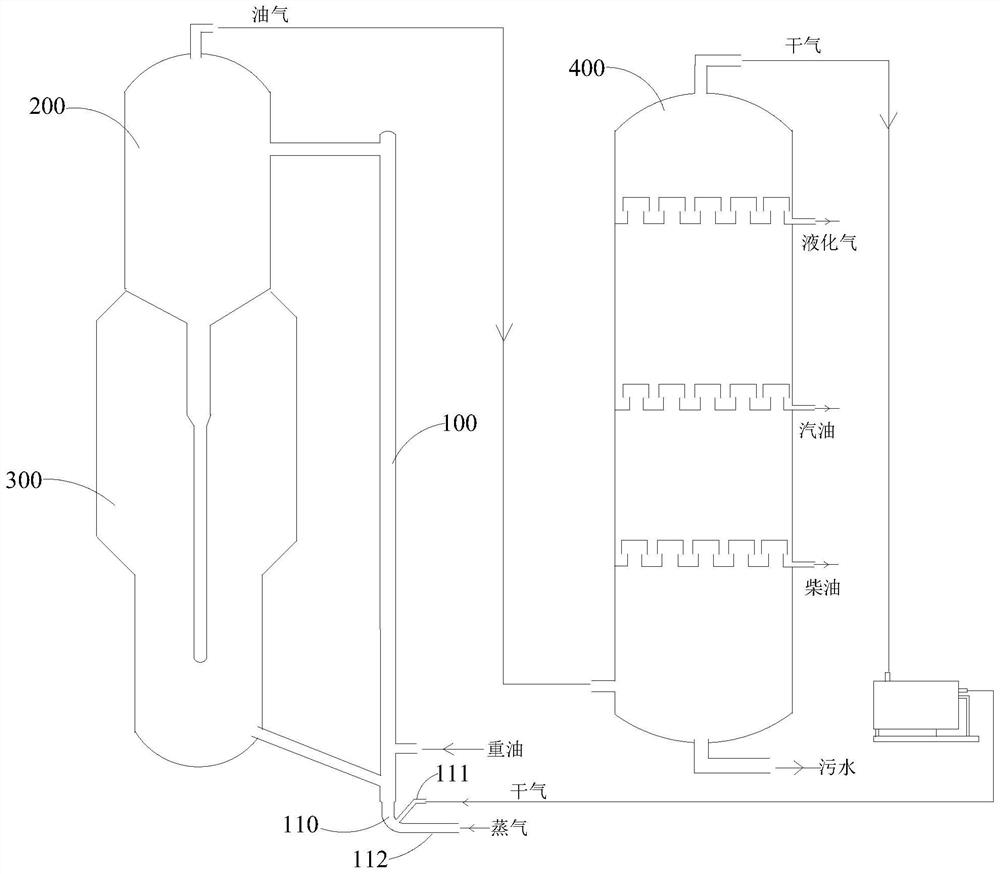

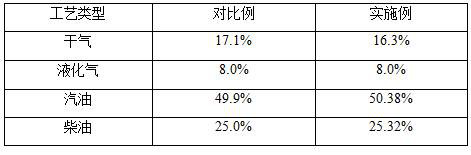

[0035] The pre-lift gas is passed into the pre-lift gas feed pipe 110 at the bottom of the riser reactor 100, and the amount of the pre-lift gas added is 1.5 t / h, wherein the dry gas is 0.15 t / h, and the steam is 1.35 t / h. The heavy oil is passed into the riser reactor 100 from the heavy oil inlet pipe, and the amount of heavy oil added is 22.8 t / h. At the same time, the catalyst enters the riser reactor 100 from the outlet of the regenerator 300 and flows upwards driven by the pre-lift gas. When the catalyst After contacting the heavy oil, the catalytic cracking reaction is carried out in the riser reactor 100. The reaction conditions in the reaction zone of the riser reactor 100 are: reaction temperature 505°C, reaction pressure 0.1MPa, and the generated oil gas enters the settler 200 together with the catalyst to realize gas solid separation, the catalyst enters the regenerator 300 from the outlet of the settler 200 for regeneration, and the regenerated catalyst flows out fr...

Embodiment 2

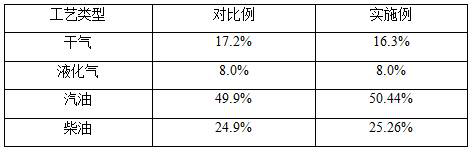

[0042]The pre-lift gas is passed into the pre-lift gas feed pipe 110 at the bottom of the riser reactor 100, and the amount of the pre-lift gas added is 1.5 t / h, of which the dry gas is 0.22 t / h, and the steam is 1.28 t / h. The heavy oil is passed into the riser reactor 100 from the heavy oil inlet pipe, and the amount of heavy oil added is 22.8 t / h. At the same time, the catalyst enters the riser reactor 100 from the outlet of the regenerator 300 and flows upwards driven by the pre-lift gas. When the catalyst After contacting the heavy oil, the catalytic cracking reaction is carried out in the riser reactor 100. The reaction conditions in the reaction zone of the riser reactor 100 are: reaction temperature 505°C, reaction pressure 0.1MPa, and the generated oil gas enters the settler 200 together with the catalyst to realize gas solid separation, the catalyst enters the regenerator 300 from the outlet of the settler 200 for regeneration, and the regenerated catalyst flows out fr...

Embodiment 3

[0049] The pre-lift gas is passed into the pre-lift gas feed pipe 110 at the bottom of the riser reactor 100, and the amount of the pre-lift gas added is 1.5 t / h, of which the dry gas is 0.27 t / h, and the steam is 1.23 t / h. The heavy oil is passed into the riser reactor 100 from the heavy oil inlet pipe, and the amount of heavy oil added is 22.8 t / h. At the same time, the catalyst enters the riser reactor 100 from the outlet of the regenerator 300 and flows upwards driven by the pre-lift gas. When the catalyst After contacting the heavy oil, the catalytic cracking reaction is carried out in the riser reactor 100. The reaction conditions in the reaction zone of the riser reactor 100 are: reaction temperature 505°C, reaction pressure 0.1MPa, and the generated oil gas enters the settler 200 together with the catalyst to realize gas solid separation, the catalyst enters the regenerator 300 from the outlet of the settler 200 for regeneration, and the regenerated catalyst flows out f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com