Layered composite material as well as preparation method and application thereof

A layered composite material and a composite material technology are applied in the field of layered composite materials and their preparation to achieve the effects of low cost of raw materials, improved selectivity of low-carbon olefins, and increased olefin ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

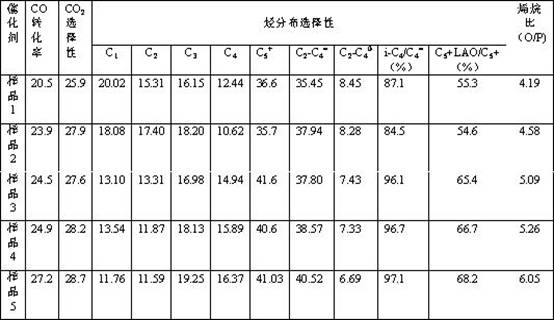

Examples

Embodiment 1

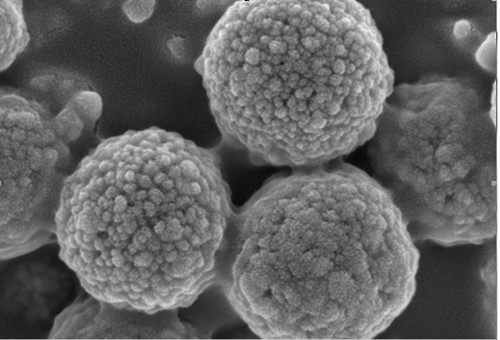

[0041] A method for preparing a layered magadiite-supported iron-based catalyst of the present embodiment, the method comprises the following steps:

[0042] (1) Preparation of Precursor 1.

[0043] Weigh 3.6 g gas phase SiO 2 , 0.7 gNaOH, 0.94 gNa 2 CO 3 Transfer to a beaker, add 120 mL of deionized water, stir magnetically for 5 min, transfer the solution to a polytetrafluoroethylene-lined autoclave, and crystallize at 220 °C for 27 h. After the reaction kettle was cooled to room temperature, it was taken out, washed, centrifuged, washed with deionized water until the pH value was 7-8, and dried overnight in a vacuum oven at 80°C to obtain precursor 1.

[0044] (2) Preparation of precursor II.

[0045] Weigh 10 g FeCl 3 ·6H 2 0 and 1 g of Triton X-100 were transferred to a beaker, then 145 mL of ethylene glycol was added to the beaker, fully dissolved to obtain a homogeneous solution. Weigh 15 g of anhydrous sodium acetate and dissolve it in 125 ml of 1-2-ethylene gly...

Embodiment 2

[0048] A method for preparing a layered magadiite-supported iron-based catalyst of the present embodiment, the method comprises the following steps:

[0049] (1) Weigh 3.6 g of gas phase SiO 2 , 0.7 gNaOH, 0.94 gNa 2 CO 3 Transfer to a beaker, add 120 mL of deionized water, stir magnetically for 5 min, transfer the solution to a polytetrafluoroethylene-lined autoclave, and crystallize at 220 °C for 27 h. After the reaction kettle was cooled to room temperature, it was taken out, washed, centrifuged, washed with deionized water until the pH value was 7-8, and dried overnight in a vacuum oven at 80°C to obtain precursor 1.

[0050] (2) Disperse 2.52 g of precursor 1 in 50 mL of deionized water, sonicate for 20 min, and mechanically stir for 12 h to obtain solution 1. 0.02 molFeCl 2 4H 2 O and 0.01 mol FeCl 3 ·6H 2 O in N 2 Add it into a three-necked flask containing 50 mL of deionized water under atmosphere, stir it mechanically for 30 min to obtain solution 2, then add ...

Embodiment 3

[0052] (1) Weigh 3.6 g of gas phase SiO 2 , 0.7 gNaOH, 0.94 gNa 2 CO 3 Transfer to a beaker, add 120 mL of deionized water, stir magnetically for 5 min, transfer the solution to a polytetrafluoroethylene-lined autoclave, and crystallize at 220 °C for 27 h. After the reaction kettle was cooled to room temperature, it was taken out, washed, centrifuged, washed with deionized water until the pH value was 7-8, and dried overnight in a vacuum oven at 80°C to obtain precursor 1.

[0053] (2) Weigh 10 g FeCl 3 ·6H 2 0 and 1 g of Triton X-100 were transferred to a beaker, then 145 mL of ethylene glycol was added to the beaker, fully dissolved to obtain a homogeneous solution. Weigh 15 g of anhydrous sodium acetate and dissolve it in 125 ml of 1-2-ethylene glycol. After fully stirring, pour it into the homogeneous solution prepared in the previous step, keep stirring for 30 min, and transfer it to polytetrafluoroethylene. In a lined high-pressure reactor, dry it in an oven at 180°...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com