A slurry bed and fixed bed serial hydrogenation process of coal tar

A slurry bed and fixed bed technology, applied in the field of coal chemical industry, can solve the problems of unreasonable utilization of hydrogen, reduced reactant concentration, low liquid fuel yield, etc., and achieve the effects of preventing deposition, improving conversion rate, and improving product quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

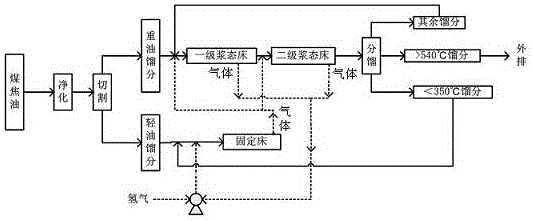

Method used

Image

Examples

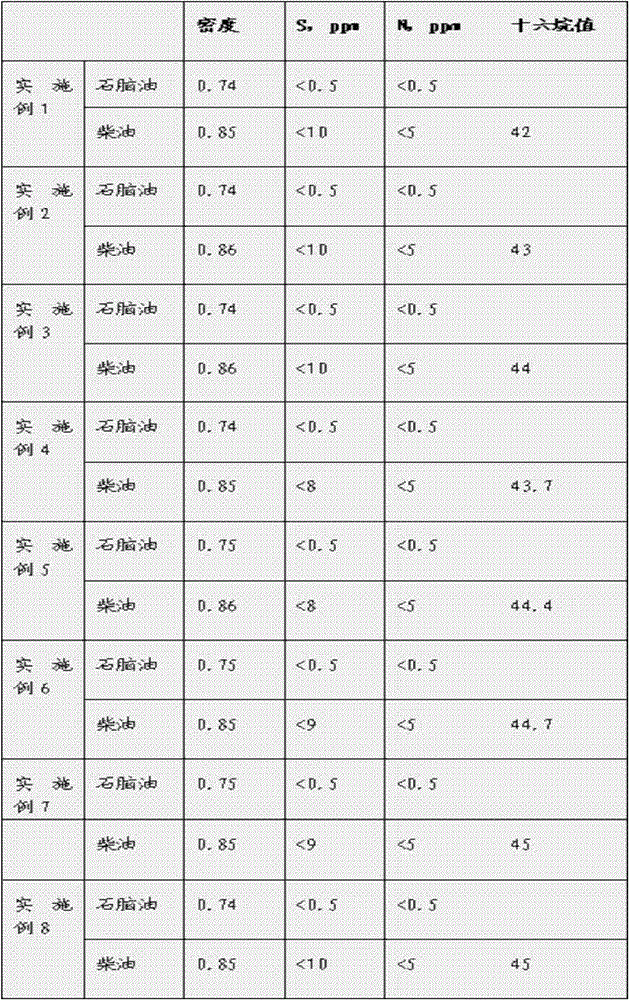

Embodiment 1

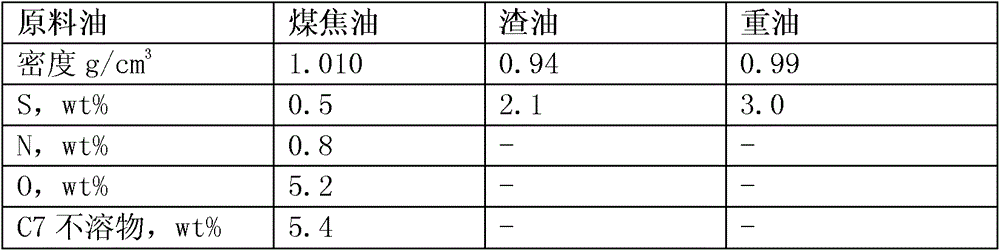

[0040] (1) Coal tar is dehydrated and purified from mechanical impurities in the purification equipment, and the water content of the dehydrated coal tar is less than 0.5wt%;

[0041] (2) Carry out vacuum distillation through the coal tar after the purification treatment in said step (1), cut into the light oil fraction less than 230 DEG C and the heavy oil fraction greater than 230 DEG C;

[0042] (3) through the light oil cut in the step (2) and H 2 Mix and mix evenly and enter the fixed bed, carry out hydrofinishing under the action of hydrofinishing catalyst, and fractionate the hydrofinishing products to obtain naphtha and diesel oil. In this step, the conditions of the fixed-bed hydrogenation reaction are as follows: temperature is 220°C, pressure is 12.0MPa, volume space velocity is 0.5h -1 , Hydrogen oil volume ratio is 500; The composition of hydrorefining catalyst is as follows: 8wt% NiO, 20wt% MoO 3 , The balance is ZSM-5 molecular sieve.

[0043] (4) combine the...

Embodiment 2

[0046] (1) The mixture of coal tar and residual oil is dehydrated and purified from mechanical impurities in the purification equipment, and the water content of the dehydrated coal tar is less than 0.5wt%;

[0047] (2) Carrying out vacuum distillation to the coal tar after the purification treatment in the step (1), cutting into light oil fractions less than 370°C and heavy oil fractions greater than 370°C;

[0048] (3) through the light oil cut in the step (2) and H 2 Mix and mix evenly and enter the fixed bed, carry out hydrofinishing under the action of hydrofinishing catalyst, and fractionate the hydrofinishing products to obtain naphtha and diesel oil. In this step, the conditions of the fixed-bed hydrogenation reaction are as follows: temperature is 260°C, pressure is 18.0MPa, volume space velocity is 0.6h -1 , The volume ratio of hydrogen to oil is 1000; the composition of the hydrorefining catalyst is as follows: 9wt% CoO, 20wt% MoO 3 , The balance is ZSM-5 molecula...

Embodiment 3

[0053] (1) In the purification equipment, the mixture of coal tar, high-sulfur oil and oil with high asphalt content is dehydrated and purified from mechanical impurities, and the water content of the dehydrated coal tar is less than 0.5wt%;

[0054] (2) Carrying out vacuum distillation to the coal tar after the purification treatment in the step (1), cutting into light oil fractions less than 240°C and heavy oil fractions greater than 240°C;

[0055] (3) through the light oil cut in the step (2) and H 2 Mix and mix evenly and enter the fixed bed, carry out hydrofinishing under the action of hydrofinishing catalyst, and fractionate the hydrofinishing products to obtain naphtha and diesel oil. In this step, the conditions of the fixed bed hydrogenation reaction are: temperature is 300°C, pressure is 14.0MPa, volume space velocity is 0.8h -1 , The volume ratio of hydrogen to oil is 1500; the composition of the hydrorefining catalyst is as follows: 8wt% CoO, 25wt% WO 3 , The ba...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com