Kenone selective hydrogenation catalyst, and preparation method and application thereof

A hydrogenation catalyst and selective technology, applied in catalyst activation/preparation, carbon-based compound preparation, chemical instruments and methods, etc. problems, to achieve high hydrogenation conversion rate and corresponding saturated ketone selectivity, improve the target product selectivity, reduce the effect of catalyst cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

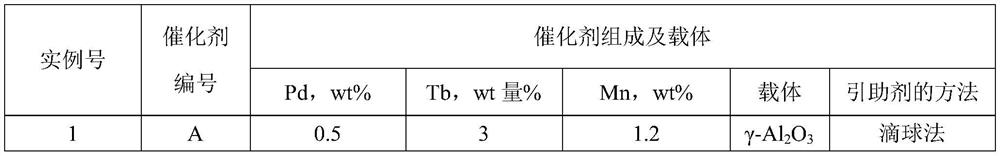

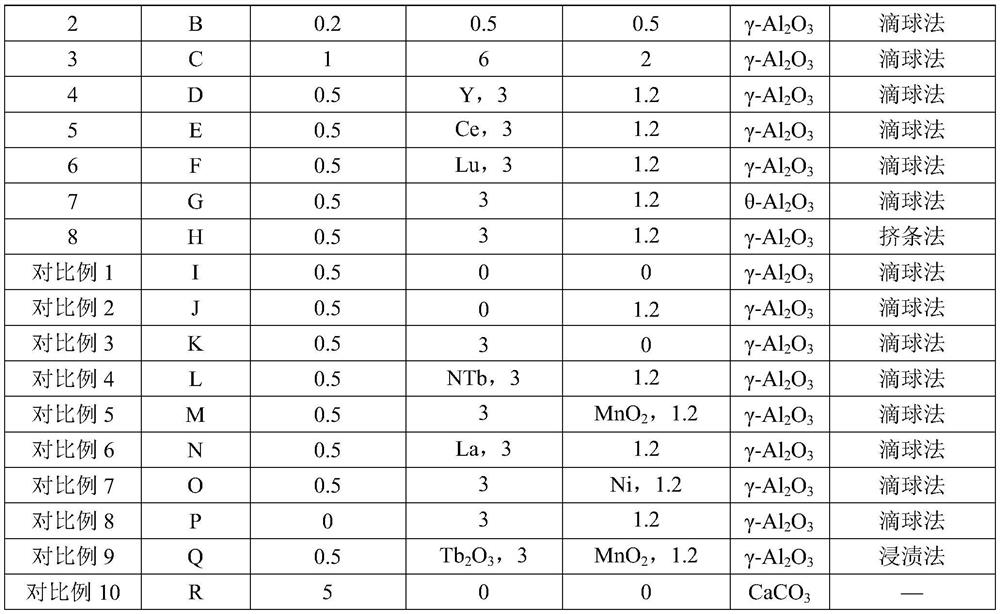

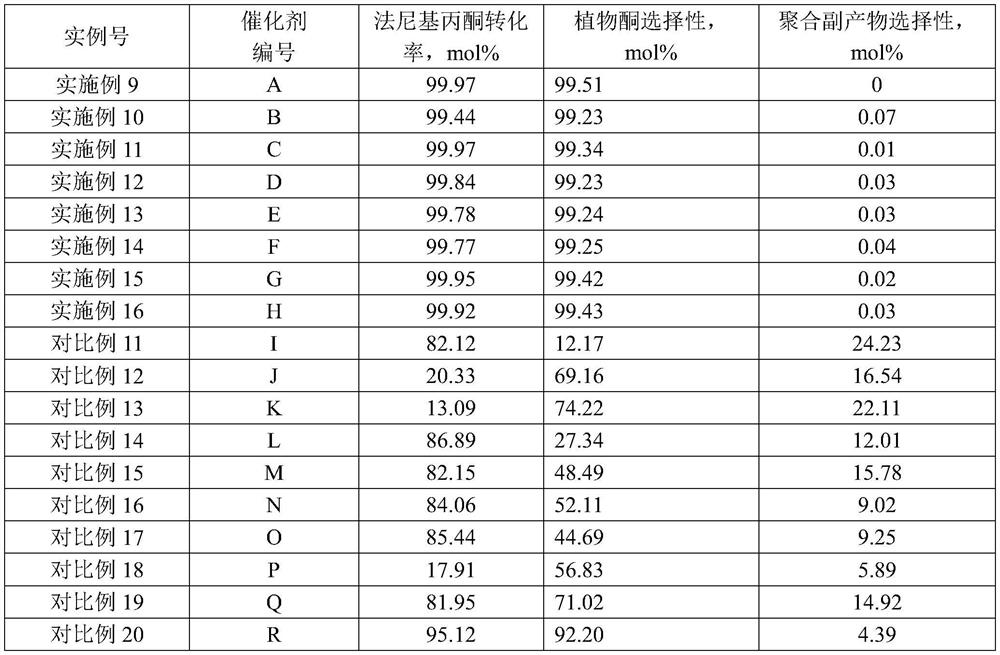

Examples

Embodiment 1

[0071] Preparation of enone selective hydrogenation catalyst:

[0072] (1) Take 10g nanometer terbium oxide and hydrogen for hydrogenation reaction, the mass space velocity is 10h -1 , the reaction temperature is 600°C, the reaction pressure is 3MPa, and the reaction time is 2h. The product obtained by the hydrogenation reaction is placed in a metal ball mill and ground for 3h under a hydrogen atmosphere to obtain TbH with a particle size of 0.01mm to 1mm. 3 particles.

[0073] (2) Get 10g of nano manganese dioxide and ammonia to carry out nitriding reaction, the mass space velocity is 5h -1 , the reaction temperature is 700°C, the reaction pressure is 2MPa, and the reaction time is 120h. The obtained product is placed in a metal ball mill and ground for 3h under an ammonia atmosphere to obtain MnN particles with a particle size of 0.01mm-1mm.

[0074] (3) Take 26.32g of pseudo-boehmite (dry basis alumina content 76wt%, 0.196mol), add 20ml of deionized water, stir for 1 hour...

Embodiment 2

[0080] Preparation of enone selective hydrogenation catalyst:

[0081] (1) Take 10g nanometer terbium oxide and hydrogen for hydrogenation reaction, the mass space velocity is 5h -1 , the reaction temperature is 700°C, the reaction pressure is 2MPa, and the reaction time is 1h. The obtained product is placed in a metal ball mill and ground for 10h under a hydrogen atmosphere to obtain TbH with a particle size of 0.02-0.08mm. 3 particles.

[0082] (2) Take 10g of nano-manganese dioxide and ammonia for nitriding reaction to prepare MnN, and the mass space velocity is 2h -1 , the reaction temperature is 800°C, the reaction pressure is 1MPa, and the reaction time is 150h. The obtained product is placed in a metal ball mill, and ground for 10h under an ammonia atmosphere to obtain MnN particles with a particle size of 0.02-0.08mm.

[0083] (3) Take 26.32g of pseudo-boehmite (produced by German Sasol company, brand SB, alumina content 76wt%), add 20ml of deionized water, stir for 1h...

Embodiment 3

[0089] Preparation of enone selective hydrogenation catalyst:

[0090] (1) Take 10g nanometer terbium oxide and hydrogen for hydrogenation reaction, the mass space velocity is 2h -1 , the reaction temperature is 500°C, the reaction pressure is 1MPa, and the reaction time is 3h. The obtained product is placed in a metal ball mill and ground for 5h under a hydrogen atmosphere to obtain TbH with a particle size of 0.02-0.1mm. 3 particles.

[0091] (2) Take 10g of nano-manganese dioxide and ammonia for nitriding reaction to prepare MnN, and the mass space velocity is 10h -1 , the reaction temperature is 500°C, the reaction pressure is 3MPa, and the reaction time is 90h. The obtained product is placed in a metal ball mill, and ground for 5h under an ammonia atmosphere to obtain MnN particles with a particle size of 0.02-0.1mm.

[0092] (3) Take 26.32g of pseudo-boehmite (dry basis alumina content 76wt%, 0.196mol), add 20ml of deionized water, stir for 1 hour to make it slurry, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com