Rare earth-containing Al-ITQ-13 zeolite and synthesis method thereof

A technology for the synthesis of al-itq-13, applied in the field of Al-ITQ-13 zeolite and its synthesis, can solve the problems of expensive template agent, cumbersome process, large proportion of non-framework aluminum, etc., and achieve good product distribution and olefin selection performance, enhanced catalytic activity, and high catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

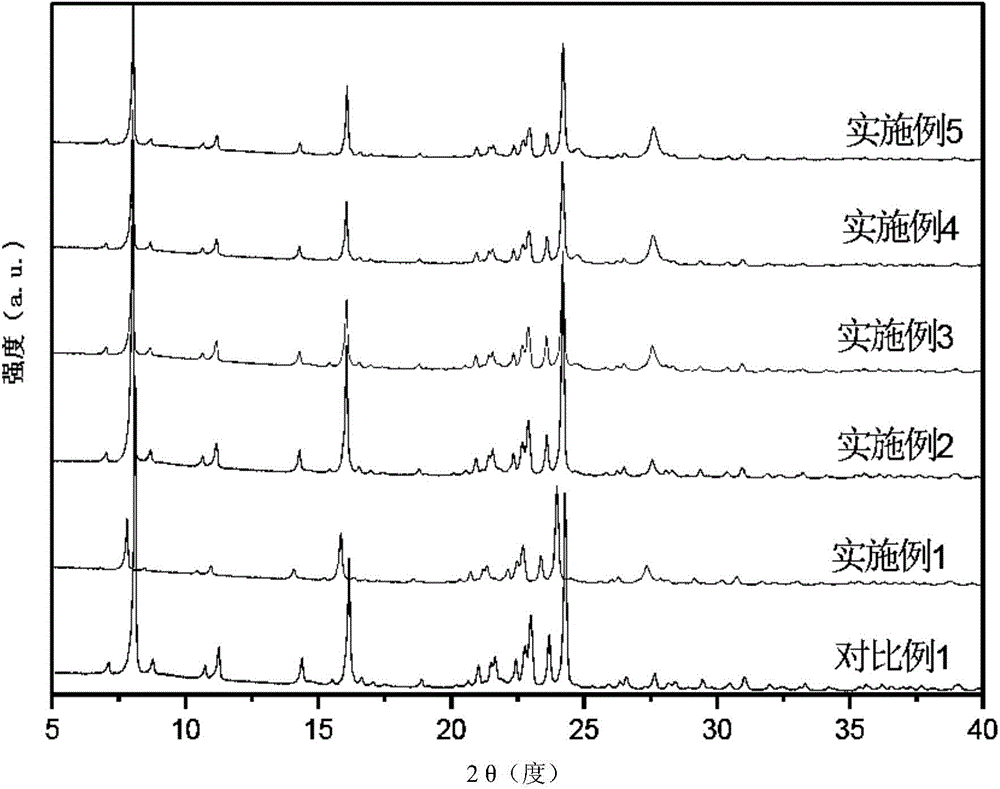

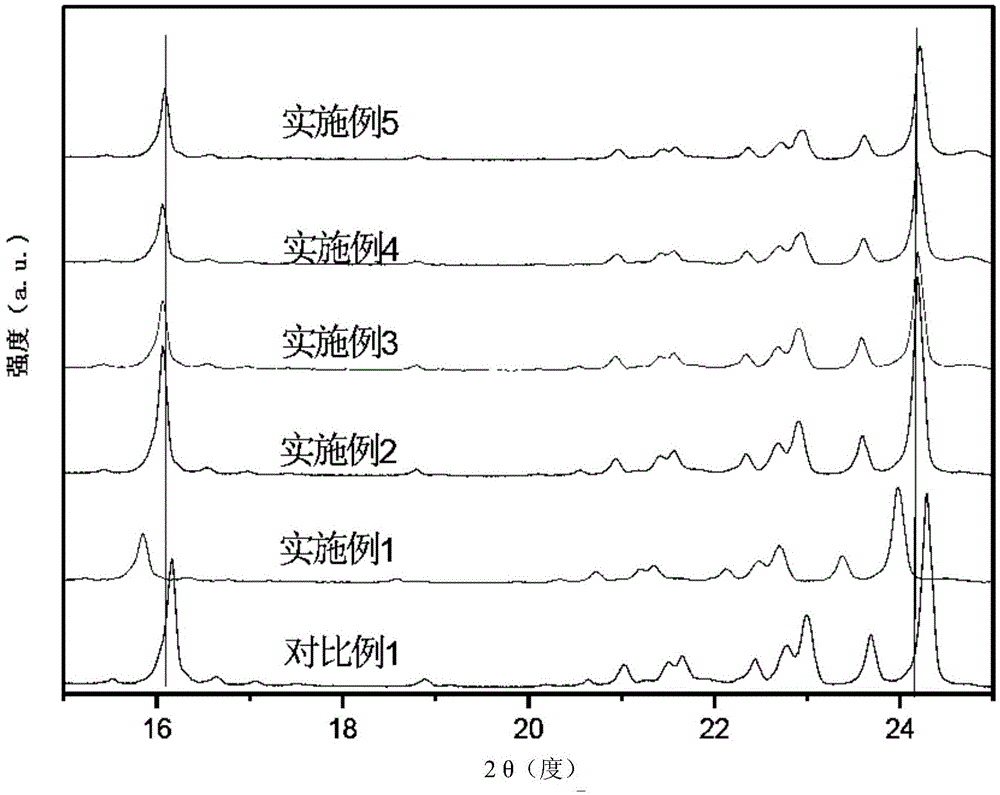

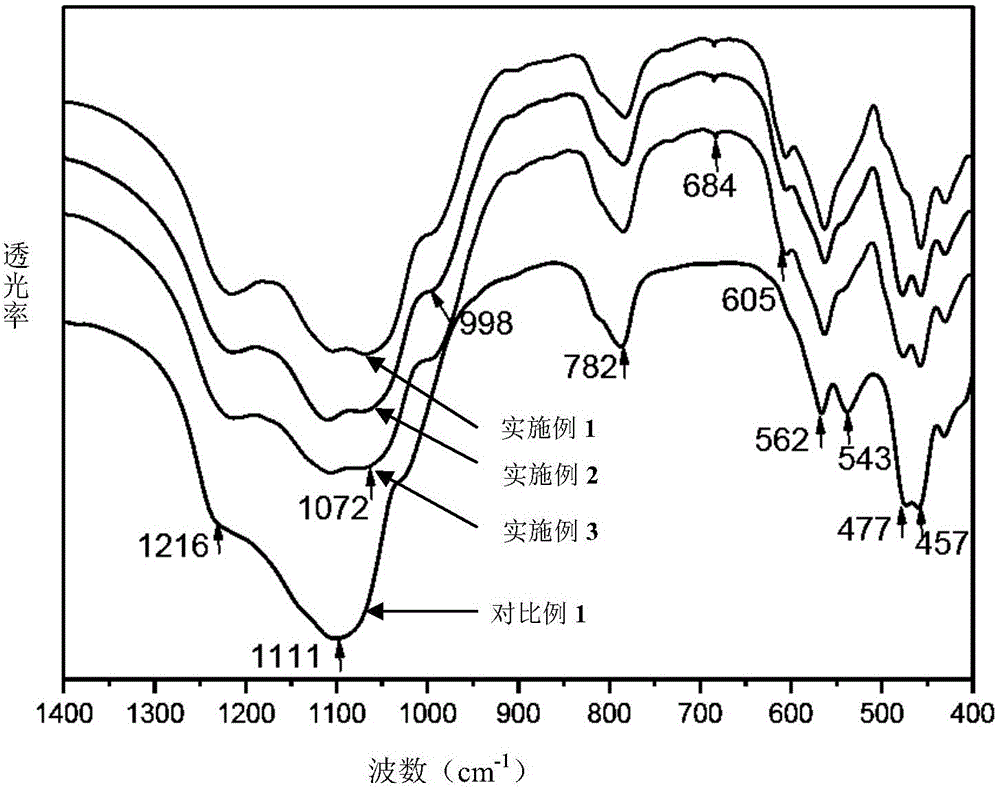

Embodiment 1

[0041] 1.0 g of lanthanum chloride (LaCl 3 ·6H 2 O) was dissolved in 10ml distilled water, then added 0.068g GeO 2 (0.65mmol) and 29.32g silica sol (n SiO2 =134.5mmol, in 27.5wt% meter), then the pH value of adding the 0.3M hydrochloric acid adjustment solution of 10.3ml is 3.0, continues to stir for 6 hours, then adds 0.5mol / L dihydroxyhexanebiammonium R in the mixture ( Oh) 2 (10mmol) aqueous solution 20mL, make mixture A; 0.18g pseudo-boehmite (n Al2O3 =1.22mmol) was dissolved in 5ml of distilled water, and 1.63g of NH 4 F (44.1mmol) to make mixture B; add mixture B to mixture A, add 0.27g of Al-ITQ-13 zeolite seed crystals after stirring, and continue stirring at a temperature of 60°C to form a homogeneous gel mixture , and then transfer it to a stainless steel reaction kettle with polytetrafluoroethylene inside, at a crystallization temperature of 180°C, after crystallization for 2 days, filter, wash, dry at 120°C overnight, and roast at 540°C for 4 hours. The produ...

Embodiment 2

[0046] Take 100 g (dry basis) of NaY zeolite with a silicon-aluminum ratio of 5.0 (measured by X-ray diffraction method) and exchange it with 2000 ml of 1% by weight lanthanum chloride solution at 90° C. for 1 hour. Filter, wash, dry at 120°C, and then calcined at 540°C for 4 hours. The calcined zeolite is exchanged and calcined for the second time by repeating the above steps. The resulting composition is La 2 o 3 19.0%, Na 2 O1.5%, Al 2 o 3 18.5%, SiO 2 61.0% REY zeolite.

[0047] Under the condition of rapid stirring at a temperature of 60°C, 0.33g of REY zeolite containing lanthanum prepared above (where n SiO2 = 3.34 mmol, n Al2O3 = 0.60 mmol, n La2O3 =1.01mmol) into 10ml of distilled water, then add 0.068g (0.65mmol) GeO 2 and 29.32g(n SiO2 =134.4mmol, in 27.5wt%) colloidal silica, then add the 0.3M hydrochloric acid of 10.3ml and adjust the pH value of the solution to be 3.0, continue stirring for 4 hours, then add 0.5mol / L dihydroxyhexanebiammonium in the mix...

Embodiment 3

[0049] Take 100 g (dry basis) of HY zeolite with a silicon-aluminum ratio of 5.8 (measured by X-ray diffraction method) and exchange it with 2000 ml of 1% by weight cerium chloride solution at 90° C. for 1 hour. Filter, wash, dry at 120°C, and then calcined at 540°C for 4 hours. The calcined zeolite is exchanged and calcined for the second time by repeating the above steps. The resulting composition is Ce 2 o 3 16.0%, Na 2 O0.5%, Al 2 o 3 21.5%, SiO 2 61.0% REHY zeolite.

[0050] Under the condition of rapid stirring at a temperature of 40°C, 5.6g of the cerium-containing REHY zeolite (where n SiO2 = 56.9 mmol, n Al2O3 = 11.8 mmol, n Ce2O3 =2.73mmol) into 100ml distilled water, then add 0.9g (8.6mmol) GeO 2 and 73.3g(n SiO2 =336.0mmol, in 27.5wt%) water glass, then the pH value of adding the 0.2M sulfuric acid adjustment solution of 56.2ml is 4.0, continues to stir for 8 hours, then adds 0.5mol / L dihydroxyl hexanebiammonium in the mixture R(OH) 2 (50mmol) aqueous s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com