Catalytic cracking catalyst and preparation method thereof

A catalytic cracking and catalyst technology, applied in catalytic cracking, physical/chemical process catalysts, molecular sieve catalysts, etc., can solve problems such as increased environmental protection pressure, increased ammonia nitrogen wastewater discharge, and increased post-treatment costs, reducing production costs and improving The effect of production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0025]Wherein, the preparation method of the first rare-earth-containing Y-type molecular sieve comprises: contacting the rare-earth-containing Y-type molecular sieve with silicon tetrachloride under stirring, the contact temperature is 100-500°C, and the contact time is 1-500°C. After 10 hours, the weight ratio of the rare earth-containing Y-type molecular sieve to silicon tetrachloride is 1:0.05-0.5;

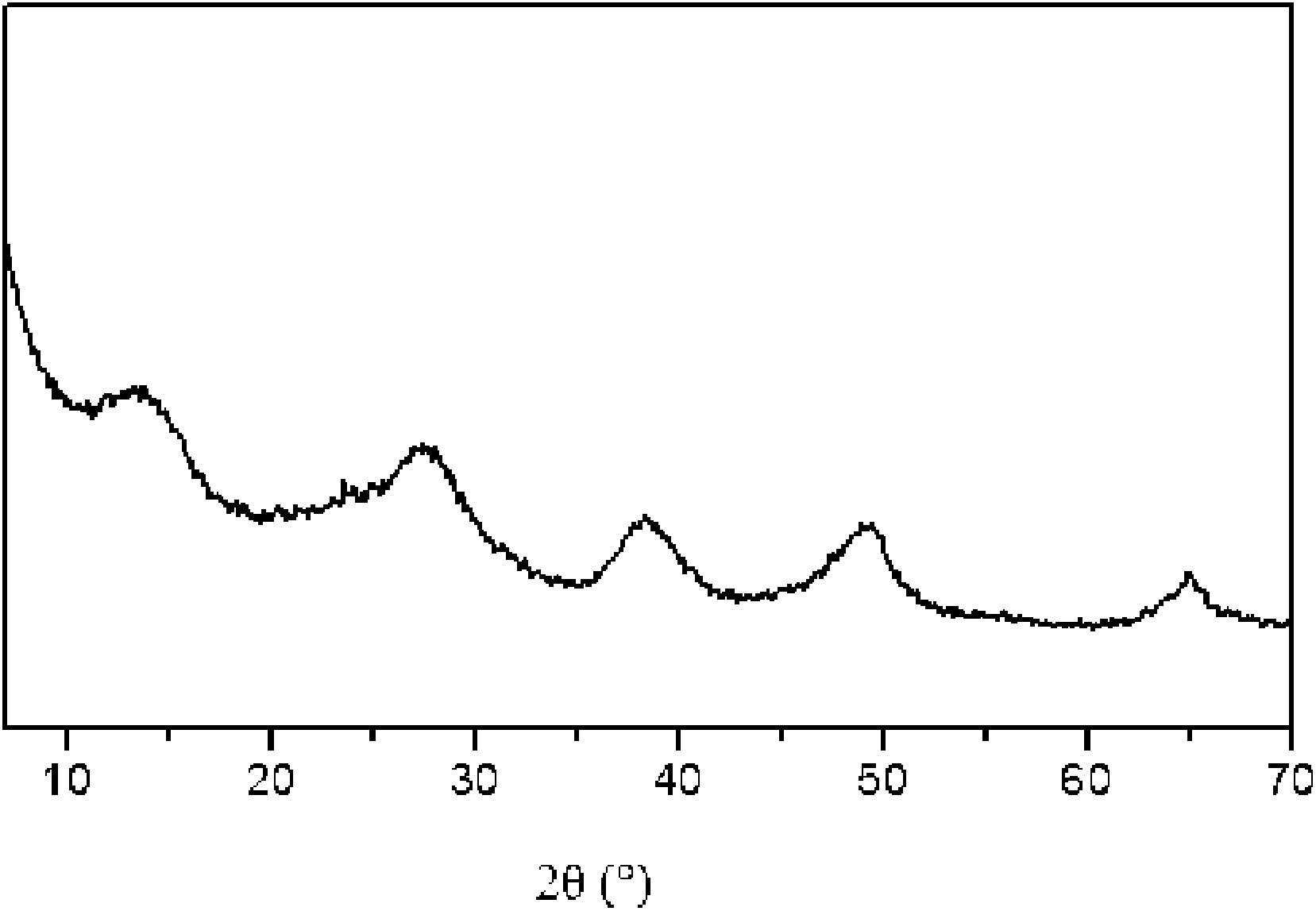

[0026] The silicon-aluminum ratio of the second rare earth-containing Y-type molecular sieve is 5-30, and the initial unit cell constant is 2.430-2.460nm, based on the total amount of the second rare-earth-containing Y-type molecular sieve and calculated as an oxide The rare earth content is 10-20% by weight, the ratio of the equilibrium unit cell constant to the initial unit cell constant is at least 0.985, wherein, X-ray diffraction analysis of the molecular sieve has two diffraction peaks at 12.43±0.06° and 11.87±0.06° at 2θ Intensity ratio I 1 / I 2 Greater than 1;

[00...

Embodiment 1

[0078] This example is used to illustrate the catalytic cracking catalyst provided by the present invention.

[0079] (1) Preparation of mesoporous silicon-aluminum materials

[0080] The concentration is 90g Al 2 o 3 / L Al 2 (SO 4 ) 3 solution and concentration is 102g Al 2 o 3 / L, NaAlO with a caustic ratio of 1.7 2 The solution is fed into the continuous gelling kettle in parallel, the effective volume of the gelling kettle is 200ml, Al 2 (SO 4 ) 3 The flow rate of the solution is 20ml / min, adjust NaAlO 2 The flow rate keeps the gelling pH value at 9, and the gelling temperature is 55°C; collect 300ml of the gelled slurry, and add 127ml of SiO with a content of 60g under stirring conditions 2 / L of water glass aqueous solution, heated to 80°C for aging for 4 hours, and then filtered.

[0081] The silicon-aluminum precipitate obtained after filtration is mixed with water at a weight ratio of 1:12 for beating, and then the hydrochloric acid solution is added into ...

Embodiment 2-7

[0085] This example is used to illustrate the catalytic cracking catalyst provided by the present invention.

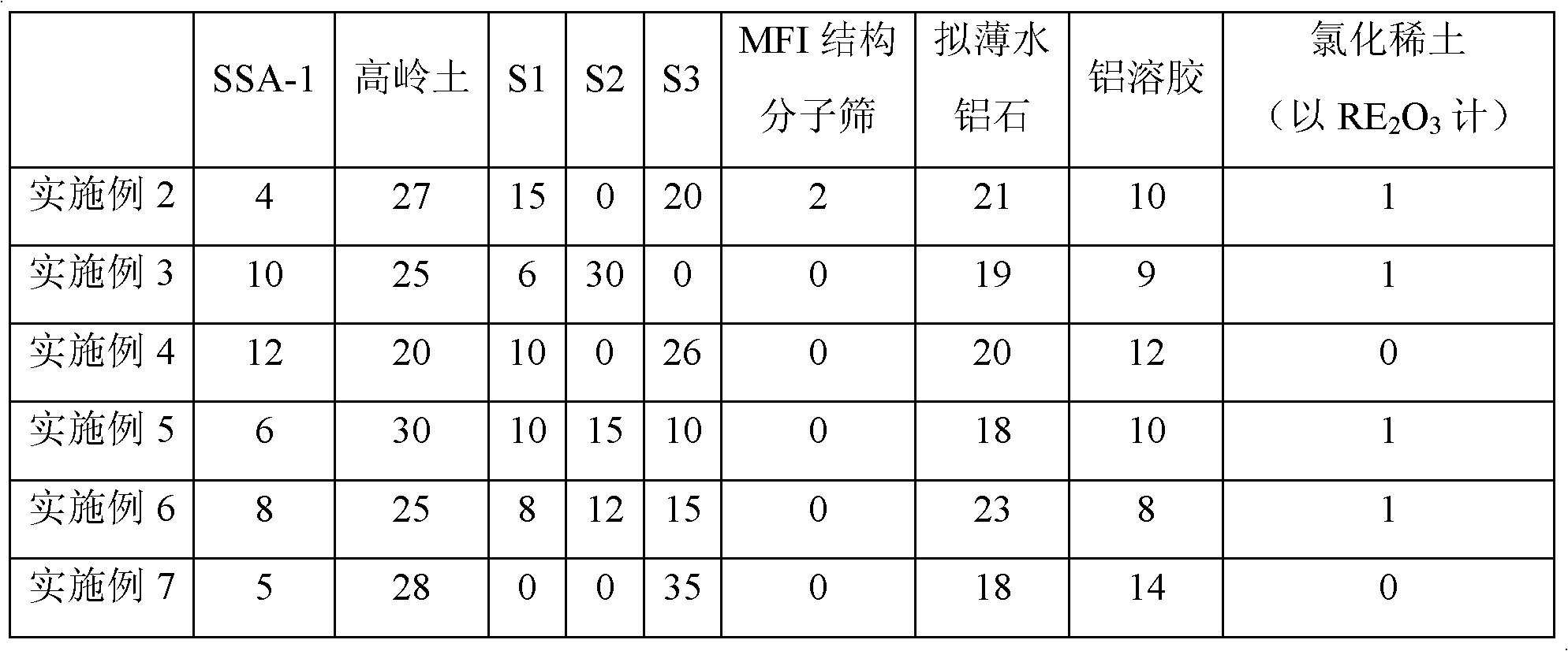

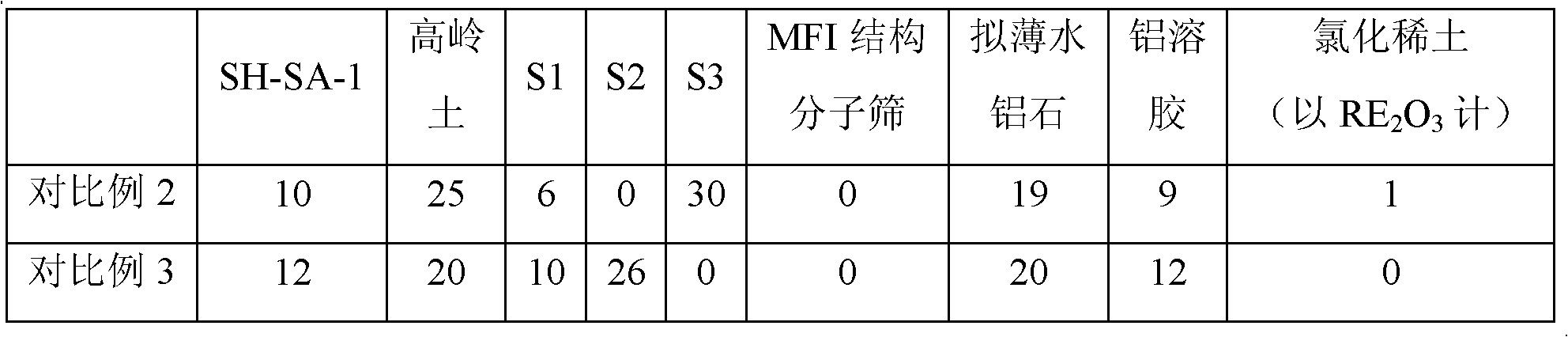

[0086] Prepare catalytic cracking catalysts according to the method of embodiment 1 respectively, difference is, in step (2), mesoporous silicon-aluminum material, kaolin, described first Y-type molecular sieve (S1) containing rare earth, described second Rare-earth-containing Y-type molecular sieve (S2), the third rare-earth-containing Y-type molecular sieve (S3), the MFI structure molecular sieve, pseudo-boehmite and aluminum sol on a dry basis, and the addition of rare earth chloride to The feeding amount of the rare earth oxide meter is shown in the following table 1 respectively, wherein, for the situation of using the embodiment of multiple molecular sieves, the multiple molecular sieves are mixed with other components in the form of mixed molecular sieve slurry; The rare earth solution is mixed with the slurries of other components and sprayed evenly after beat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com