A kind of catalytic cracking catalyst and its preparation method and application

A catalytic cracking and catalyst technology, used in catalytic cracking, physical/chemical process catalysts, molecular sieve catalysts, etc., can solve problems such as disadvantages, and achieve the effect of improving selectivity, high catalytic cracking activity, and ensuring gasoline yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

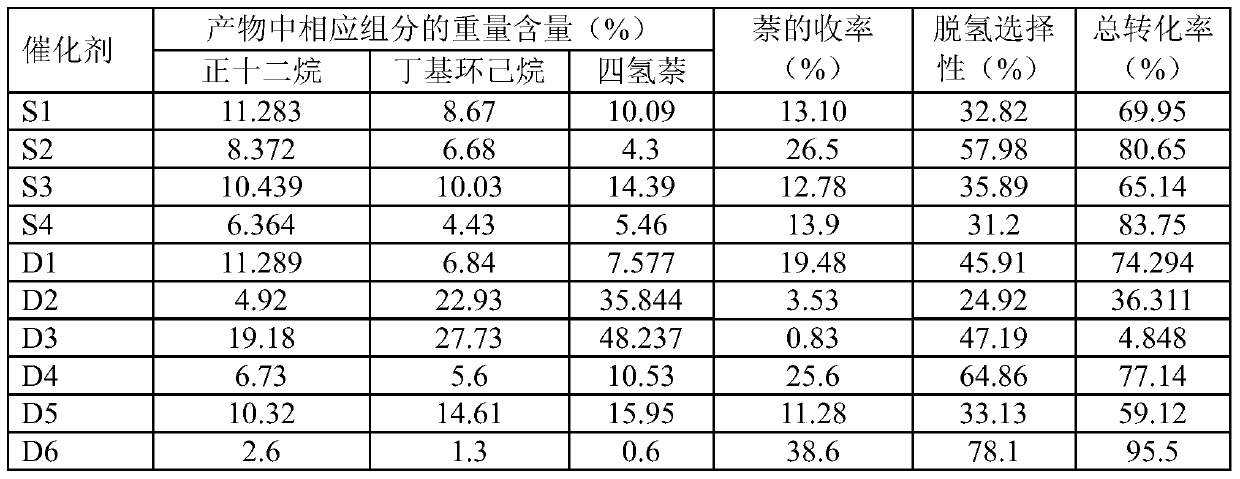

Examples

preparation example Construction

[0018] According to the catalytic cracking catalyst provided by the present invention, there is no special requirement for the ultra-stable IM-5 molecular sieve, which can be prepared by referring to conventional technical methods. However, in a preferred embodiment of the present invention, the preparation method of the ultra-stable IM-5 molecular sieve comprises: exchanging the IM-5 molecular sieve with an ammonium salt solution until the Na content in the molecular sieve is lower than 0.3% by weight So far, and then calcined in a water vapor atmosphere to obtain the ultra-stable IM-5 molecular sieve.

[0019] More preferably, the preparation method of the above-mentioned super stable IM-5 molecular sieve comprises:

[0020] A1. Exchange the IM-5 molecular sieve with the ammonium salt solution until 75% to 90% by weight of Na in the molecular sieve is removed. ℃ calcination (preferably calcination 2.5-4.5h), to obtain cross-calcination IM-5 molecular sieve;

[0021] A2. Th...

Embodiment 1

[0052] This example is used to illustrate the catalytic cracking catalyst provided by the present invention and its preparation method.

[0053] (1) The preparation method of ultra-stabilized IM-5 molecular sieve comprises the following steps:

[0054] A1. Mix IM-5 molecular sieve and deionized water at a weight ratio of 1:10 to form a water slurry of IM-5 molecular sieve. The water slurry is mixed with an aqueous solution of ammonium chloride, and exchanged at a temperature of 40°C until 90% by weight of Na in the molecular sieve is removed (the exchange step can be divided into several times, and the solution is stirred for 60 minutes each time to obtain a suspension and carry out suction filtration , after the filter cake is dried, measure the Na content in the molecular sieve by X-ray fluorescence method, if the Na content does not meet the requirements, repeat the previous steps), wash with deionized water to remove residual salt, and bake at 800 ° C for 2.5 h under 100% ...

Embodiment 2

[0063] This example is used to illustrate the catalytic cracking catalyst provided by the present invention and its preparation method.

[0064] (1) The preparation method of the ultra-stabilized IM-5 molecular sieve: with reference to the step (1) of Example 1;

[0065] (2) The preparation method of the ultra-stabilized USY molecular sieve: refer to the step (2) of Example 1;

[0066] (3) The preparation method of catalytic cracking catalyst: with reference to the step (3) of embodiment 1, difference is: after obtaining fresh catalyst, do not carry out hydrothermal aging treatment, the obtained catalyst is denoted as S2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com