Anti-basic nitrogen liquefied gas yield increase cracking catalyst and preparation method thereof

A cracking catalyst, liquefied gas technology, applied in physical/chemical process catalysts, catalytic cracking, molecular sieve catalysts, etc., can solve the problems of low activity, no alkali-resistant nitrogen-producing liquefied gas cracking catalyst, and deterioration of product distribution, etc. Achieve the effect of high liquefied gas yield, high catalytic cracking activity and high conversion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0053] The present invention also provides a kind of preparation method of the described catalytic cracking catalyst of resisting alkaline nitrogen and producing liquefied gas more, the method comprises the following steps:

[0054] (1) Using NaY molecular sieve as raw material, after rare earth exchange and roasting, "cross-baking" RENaY is obtained; then react with rare earth compounds, iron-containing substances, copper-containing substances, phosphorus-containing substances, and ammonium salts to obtain The Y molecular sieve product modified with rare earth and iron / copper / phosphorus is the active component of the first Y molecular sieve described in the present invention;

[0055] Wherein, the process of "cross-baking" RENaY is well known to those skilled in the art, usually NaY and rare earth compound are mixed in NaY:RE 2 o 3 =1:0.10-0.25 (weight ratio), pH=2.0-4.5, exchange temperature 25-100°C for 0.3-1.5 hours, filter, wash, filter cake at 400-850°C, 0-100% steam I...

Embodiment 1

[0075] This example is used to illustrate the catalytic cracking catalyst provided by the present invention.

[0076](1) Preparation of modified Y-type molecular sieve

[0077] In the reactor, add 5.0 kilograms of NaY molecular sieves on a dry basis (Changling Catalyst Factory provides, crystallinity 86%, skeleton silicon-aluminum ratio (SiO 2 / Al 2 o 3 molar ratio) 5.2) and 4 kg of deionized water, slowly add 4.0 liters of rare earth chloride solution (provided by Qilu Catalyst Factory, RE 2 o 3 content of 222.5 grams per liter), adjust the system pH=3.5 with 4% by weight dilute hydrochloric acid, heat up to 90°C and stir for 1.5 hours, filter, wash, and dry; then bake at 650°C and 100% steam atmosphere for 2 hours to prepare Get "cross-baked" rare earth sodium Y, which is recorded as modified molecular sieve ABY-1A.

[0078] Take 2.0 kg of modified molecular sieve ABY-1A dry basis and put it into the reaction kettle, add 1.6 kg of deionized water, and slowly add 0.50 li...

Embodiment 2-7

[0085] This example is used to illustrate the catalytic cracking catalyst provided by the present invention.

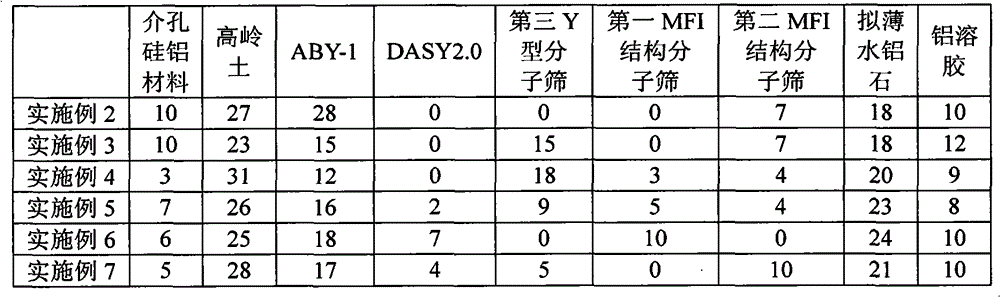

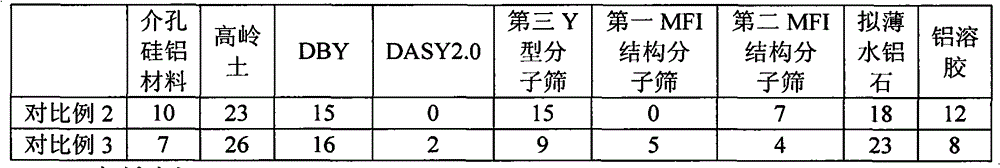

[0086] Prepare catalytic cracking catalyst according to the method of embodiment 1 respectively, difference is, in step (2), mesoporous silicon aluminum material, kaolin, described first Y-type molecular sieve ABY-1, described second Y-type molecular sieve The feed amounts of DASY2.0, the third Y-type molecular sieve, the first MFI structure molecular sieve, the second MFI structure molecular sieve, pseudo-boehmite and aluminum sol on a dry basis are shown in Table 2 below. , when there are multiple molecular sieves in the formula, they are all added in the form of molecular sieve mixed slurry, and the feeding amount of each component is in parts by weight, so as to prepare catalytic cracking catalysts C2-C7 respectively.

[0087] Table 2

[0088]

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com