Method for producing high octane gasoline through naphtha

A high-octane gasoline and naphtha technology, which is applied in the petroleum industry, hydrocarbon oil treatment products, and hydrocarbon oil treatment, can solve unrelated problems and achieve the goal of increasing gasoline yield, optimizing gasoline composition, and increasing content Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

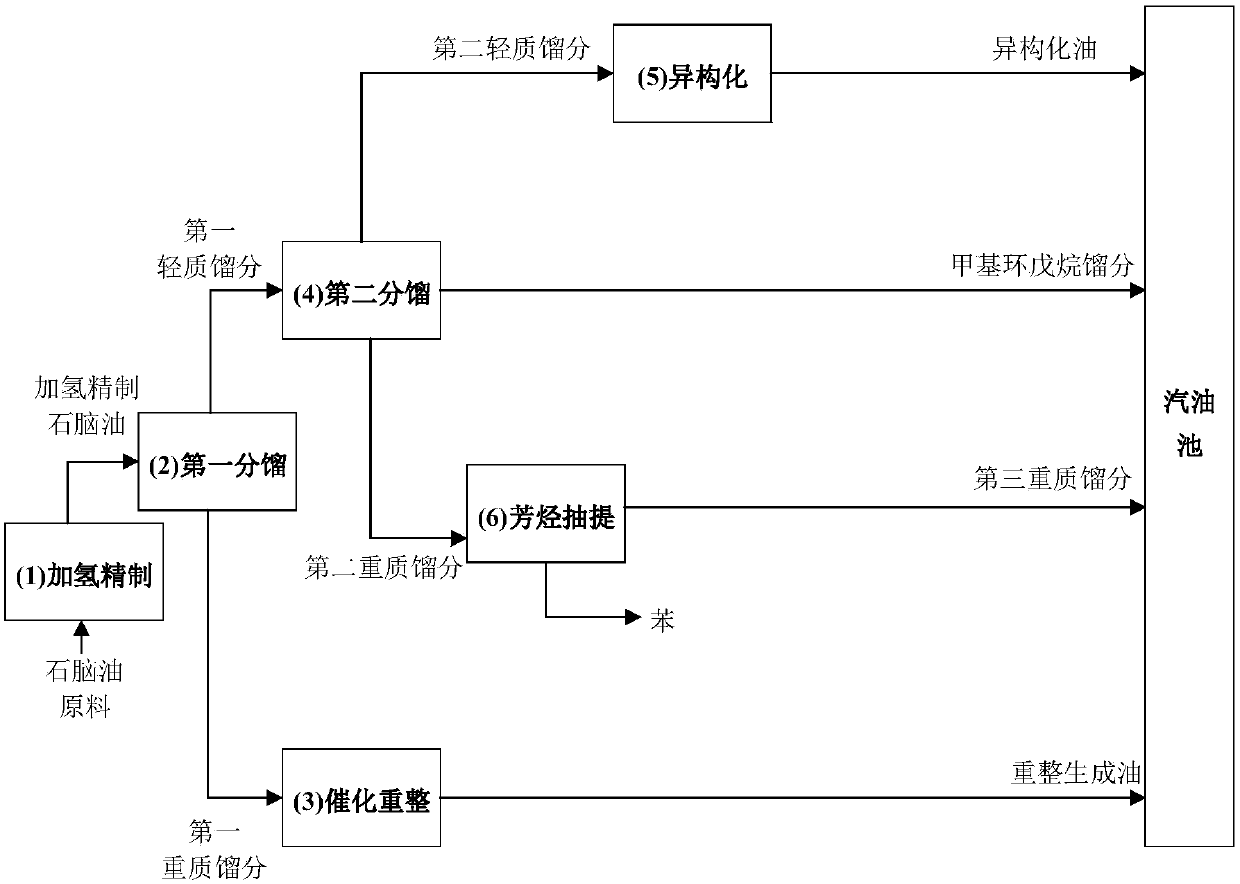

Method used

Image

Examples

Embodiment approach

[0029] In one embodiment, the catalytic reforming catalyst is prepared by a conventional method. Specifically, a shaped inorganic oxide carrier, such as a spherical or strip-shaped carrier, can be prepared first, and then impregnated to introduce the first metal component and halogen, if The catalyst contains the second metal component and / or the third metal component, preferably the second metal component and / or the third metal component are introduced into the carrier first, and finally the first metal component and halogen are introduced, and all The carrier after the metal component is dried and calcined at 450-650° C. to obtain an oxidized catalytic reforming catalyst. The catalytic reforming catalyst in an oxidized state needs to be reduced in a hydrogen-containing atmosphere at 315-650°C before use to obtain a catalytic reforming catalyst in a reduced state.

[0030] In the present invention, the second fractionation in step (4) is used to obtain the second light fracti...

example

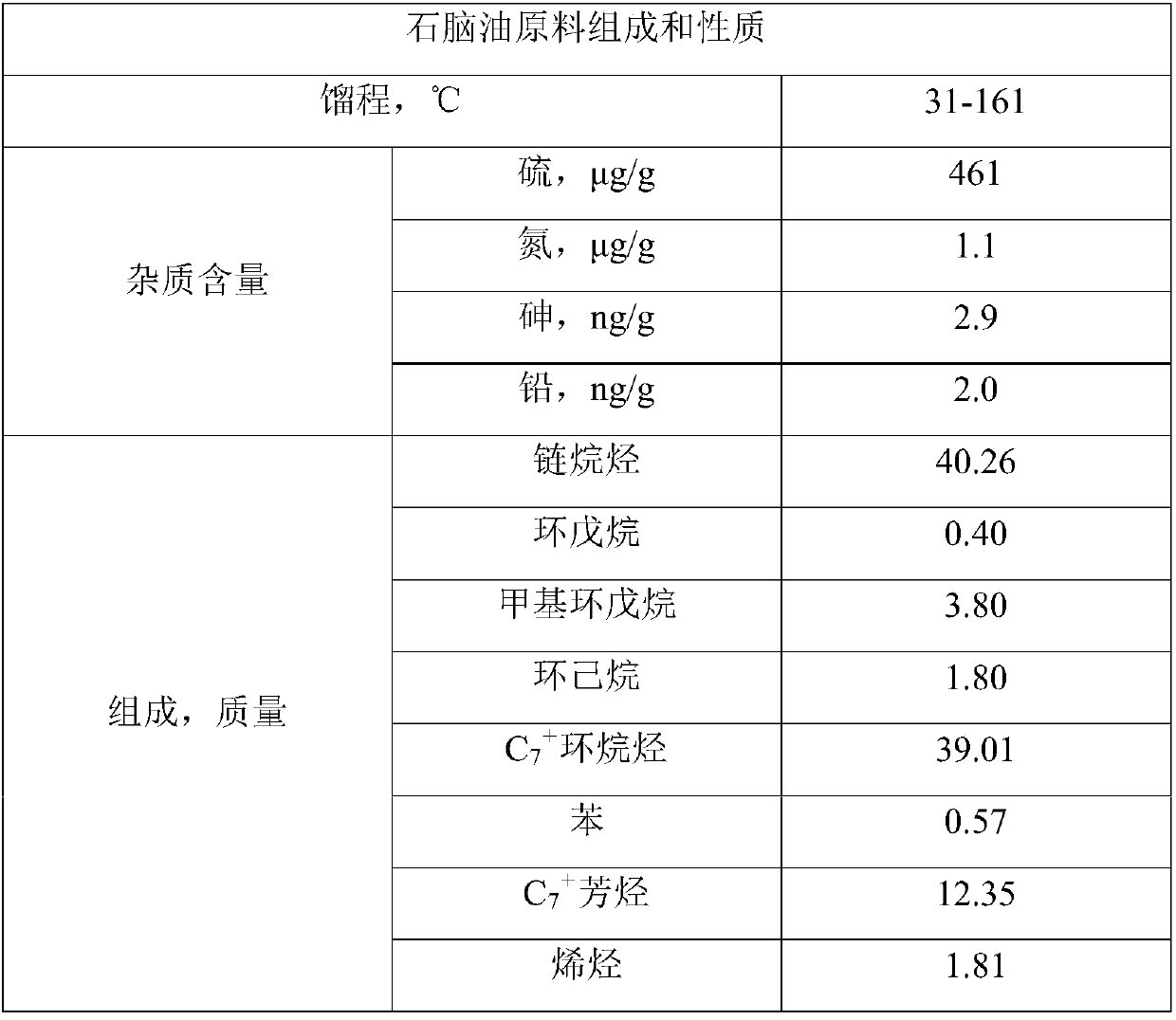

[0051] (1) Hydrofining of naphtha raw materials.

[0052] In a 20 milliliter fixed-bed continuous flow reactor, 20 milliliters of hydrofinishing catalyst A is filled, and on a dry basis, the hydrofinishing catalyst A contains 0.03 mass % of CoO, 2.0 mass % of NiO, and 18.5 mass % of WO 3 , 0.5% by mass of Cl and 78.97% by mass of Al 2 o 3 .

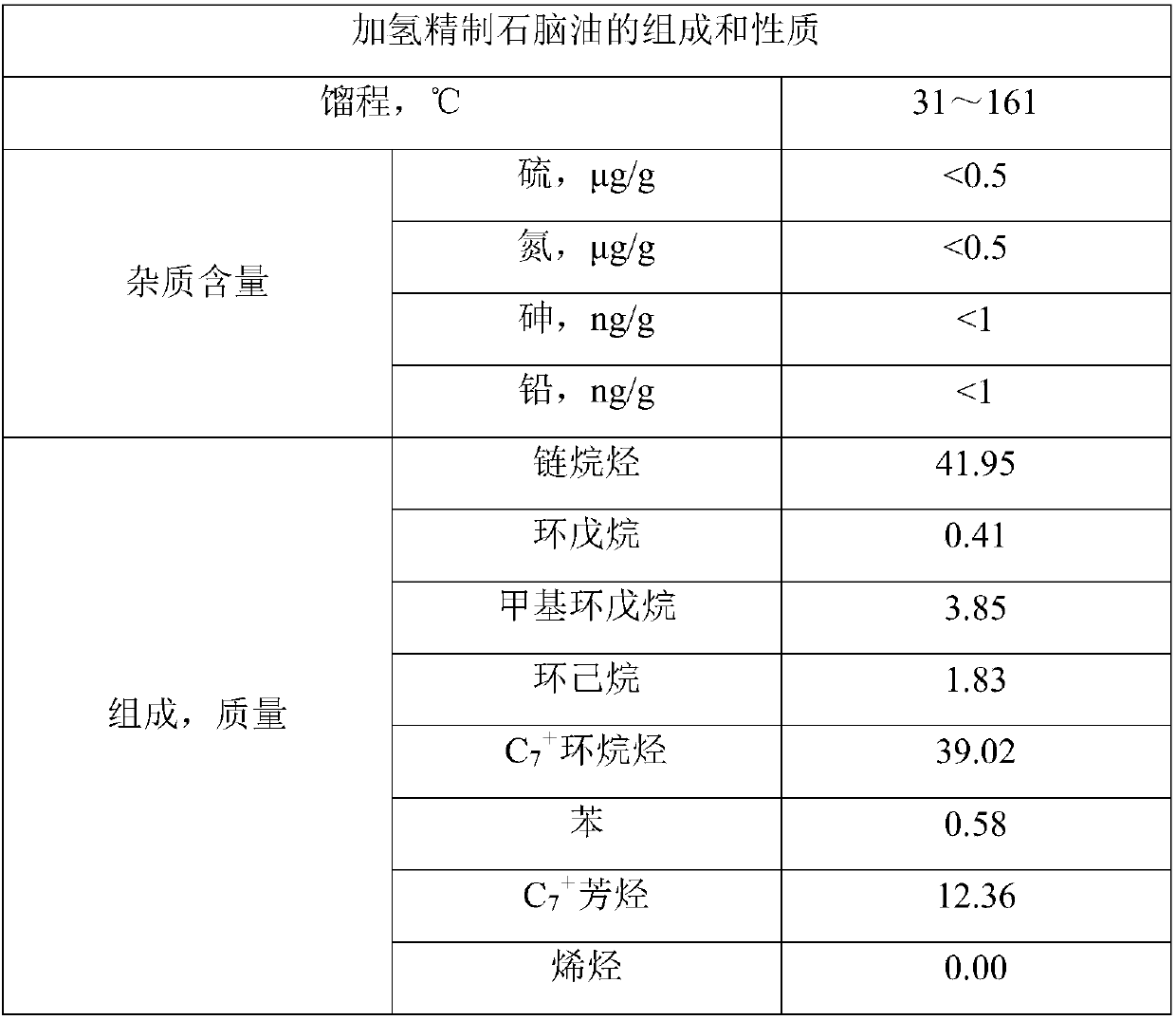

[0053] The naphtha feedstock whose composition and properties are shown in Table 1 was heated at 290°C, pressure 2.0MPa, hydrogen / hydrocarbon volume ratio 200:1, feed volume space velocity 8.0h -1 Under the condition of passing through in the reactor of above-mentioned packing catalyst A to carry out hydrorefining. The reaction product was sent to a water cooler, separated into gas-liquid two phases, measured separately and analyzed for composition. The composition and properties of the hydrorefined naphtha obtained after hydrofinishing are shown in Table 2.

[0054] (2) The first fractionation of hydrotreated naphtha.

[0055] In the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com