Catalytic cracking catalyst and preparation method thereof

A catalytic cracking and catalyst technology, applied in the direction of physical/chemical process catalysts, molecular sieve catalysts, chemical instruments and methods, etc., can solve the problem of low gasoline yield and achieve the effects of decreased heavy oil yield, high activity, and improved cracking performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

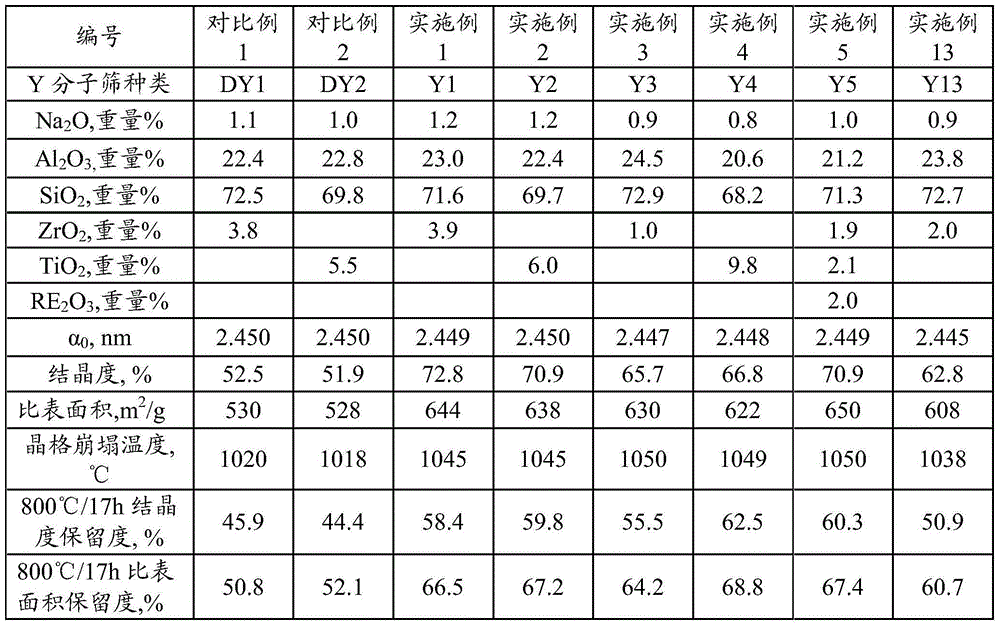

[0040] 27.9g zirconium nitrate Zr(NO 3 ) 4 ·5H 2 O was dissolved in 500g deionized water, stirred evenly, adjusted the pH value of the mixture to 4.5 with dilute ammonia water, then raised the temperature to 40°C, and continued to stir for 60min; take 200g (dry basis weight) of DY1-1 molecular sieve provided in Comparative Example 1 and add into the above mixture, stirred at 40°C for 2 hours; after filtration, the obtained filter cake was roasted at 650°C and 100% water vapor for 2 hours to obtain a zirconium-modified Y molecular sieve, denoted as Y1, and its properties are shown in Table 1 . After the Y1 molecular sieve was aged at 800°C and 100% water vapor for 17 hours, its crystallinity and specific surface area were measured, and the crystallization retention and specific surface area retention were calculated. The results are listed in Table 1.

[0041] The cracking catalyst was prepared according to the method of Comparative Example 1, except that an equal amount of ...

Embodiment 2

[0043] Dissolve 51.2g of tetrabutyl titanate in 800g of deionized water, stir evenly, adjust the pH value of the mixture to 6.0 with dilute ammonia water, then stir at room temperature for 30min; take 200g of DY1-1 molecular sieve provided in Comparative Example 1 (dry Basis weight) was added to the above mixture, the temperature was raised to 60°C, and stirring was continued for 1 hour; after filtration, the obtained filter cake was roasted at 500°C and 100% steam for 3 hours to obtain a titanium-modified Y molecular sieve, denoted as Y2 , whose properties are shown in Table 1. After the Y2 molecular sieve was aged at 800°C and 100% water vapor for 17 hours, its crystallinity and specific surface area were measured, and the crystallization retention and specific surface area retention were calculated. The results are listed in Table 1.

[0044] The cracking catalyst was prepared according to the method of Comparative Example 2, except that an equal amount of Y2 molecular siev...

Embodiment 3

[0046] 5.2g zirconium oxychloride ZrOCl 2 ·8H 2 Dissolve O in 1800g deionized water, stir well, adjust the pH value of the mixture to 7.0 with dilute ammonia water, raise the temperature to 80°C, and stir for 20min; take 200g (dry weight) of DASY (0.0) molecular sieves and add them to the above mixture, at 80 Stir at °C for 2 hours; filter, and roast the obtained filter cake at 450°C and 100% water vapor for 5 hours to obtain a zirconium-modified Y molecular sieve, denoted as Y3, and its properties are shown in Table 1. After the Y3 molecular sieve was aged at 800°C and 100% water vapor for 17 hours, its crystallinity and specific surface area were measured, and the crystallization retention and specific surface area retention were calculated. The results are listed in Table 1.

[0047]Mix 323g of pseudo-boehmite and 1478g of deionized water, stir for 30 minutes to obtain a pseudo-boehmite slurry, adjust the pH of the slurry to 3.8 with dilute hydrochloric acid, and age at 60...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| crystallinity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com