Catalytic material containing rare earth and magnesium and preparation method thereof

A catalytic material and rare earth technology, applied in chemical instruments and methods, catalytic cracking, molecular sieve catalysts, etc., can solve the problems of large steric hindrance effect, high price, easy structure collapse, etc., and achieve the effect of promoting the conversion capacity of heavy oil

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0038] The preparation process of the directing agent adopted in the embodiment is: 5700g water glass (Changling Catalyst Company provides, SiO 2 261g / L, modulus 3.31, density 1259g / L) is put into the beaker, add 4451g perbasic sodium metaaluminate (provided by Changling Catalyst Company, Al 2 o 3 39.9g / L, Na 2 O 279.4g / L, density 1326g / L) and aged at 30°C for 18 hours, a molar ratio of 16.1Na 2 O: Al 2 o 3 :15SiO2 2 :318.5H 2 O's directing agent.

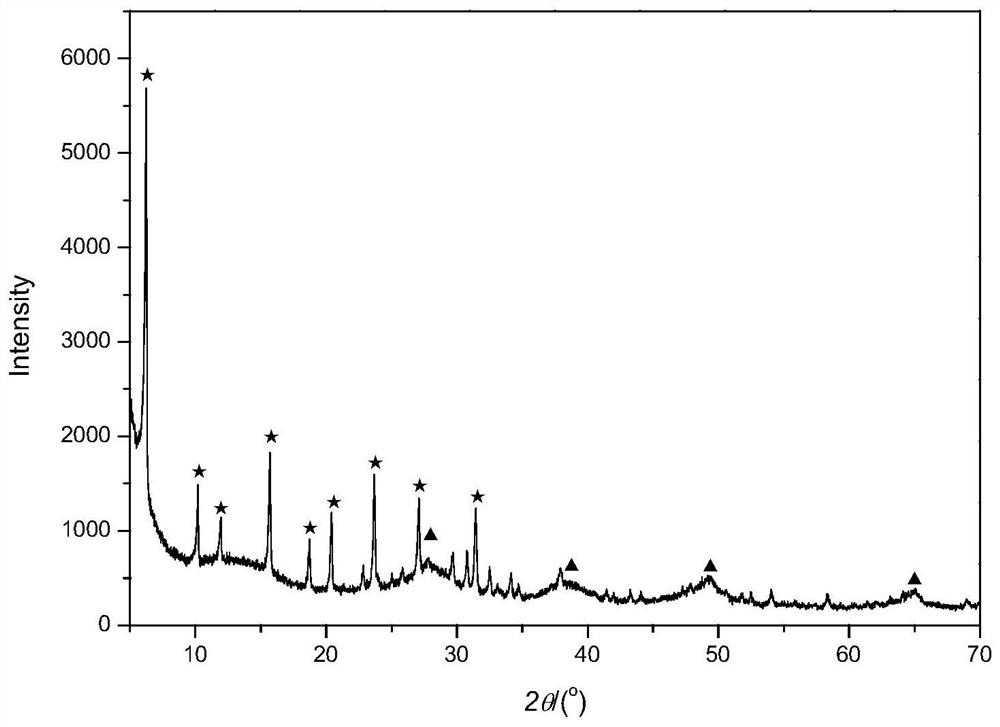

[0039] The chemical composition of the porous material mesoporous layer in the examples was determined by X-ray photoelectron spectroscopy. Rare earth content and magnesium oxide content were measured by X-ray fluorescence method (see "Petrochemical Analysis Method (RIPP Experimental Method)", edited by Yang Cuiding et al., Science Press, published in 1990). The phase, unit cell constant and crystallinity were determined by X-ray diffraction method. The crystallinity is determined according to the industry standards SH / T...

Embodiment 1

[0043] Under vigorous stirring, mix water glass, aluminum sulfate, sodium metaaluminate, guiding agent and deionized water according to 7.5SiO 2 :Al 2 o 3 : 2.15Na 2 O: 190H 2 The molar ratio of O is mixed to form a NaY molecular sieve gel, in which the mass ratio of the directing agent is 5%, and after continuous stirring at room temperature for 1 hour, the gel is placed in a crystallization kettle for static crystallization treatment at 100°C After 40 hours of crystallization, cool down rapidly and filter and wash the crystallization slurry to obtain a NaY molecular sieve filter cake; re-add water to the obtained NaY molecular sieve filter cake, disperse evenly, and mix Al 2 (SO 4 ) 3 Solution (concentration 89gAl 2 o 3 / L) and NaAlO 2 Solution (concentration 156gAl 2 o 3 / L) is added wherein to react simultaneously, and the pH value of slurry system in the control reaction process is 9.5, after adding certain hour, according to used Al 2 (SO 4 ) 3 solution and ...

Embodiment 2

[0049] The preparation of NaY molecular sieve is the same as in Example 1, the difference is that the crystallization treatment time is 24 hours; the obtained NaY molecular sieve filter cake is re-added with water for beating, and after being dispersed evenly, at room temperature and under vigorous stirring, the Al(NO 3 ) 3 Solution and ammoniacal liquor are added wherein to react simultaneously, and the pH value of slurry system in the control reaction process is 10.1, after adding certain hour, according to used Al(NO 3 ) 3 Al in solution 2 o 3 By weight, according to SiO 2 :Al 2 o 3 = 1:1.8 weight ratio, add the required tetraethoxy silicon into the reaction system, continue to age at 65°C for 6 hours, filter after aging, wash and dry at 120°C to obtain the porous material SAYN -6.

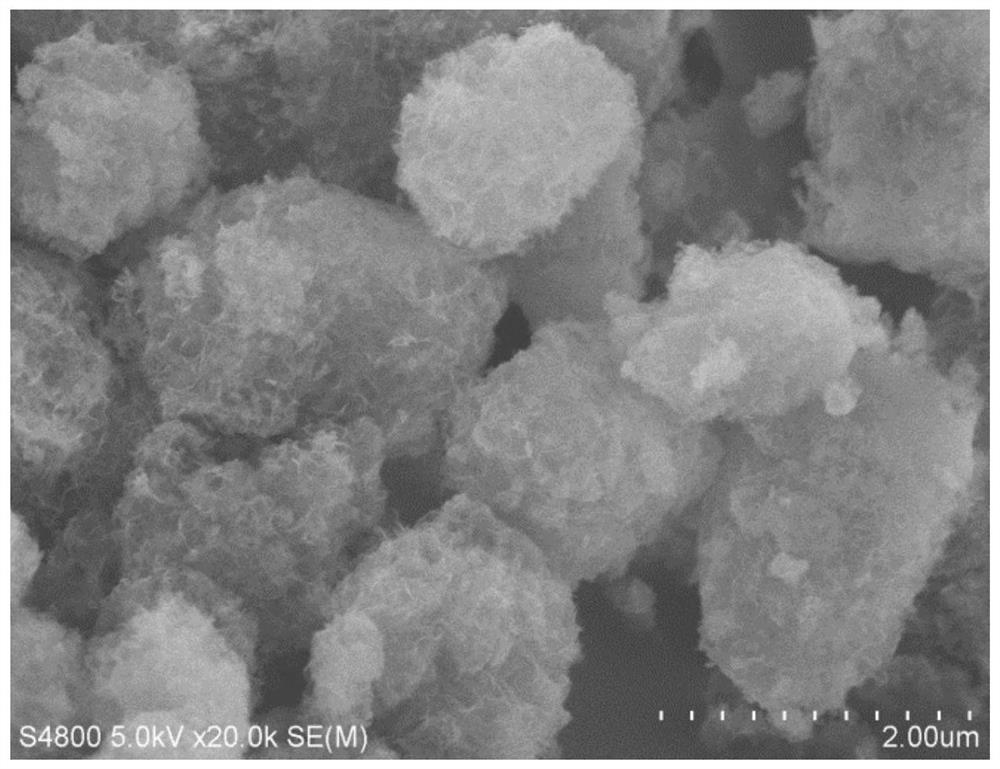

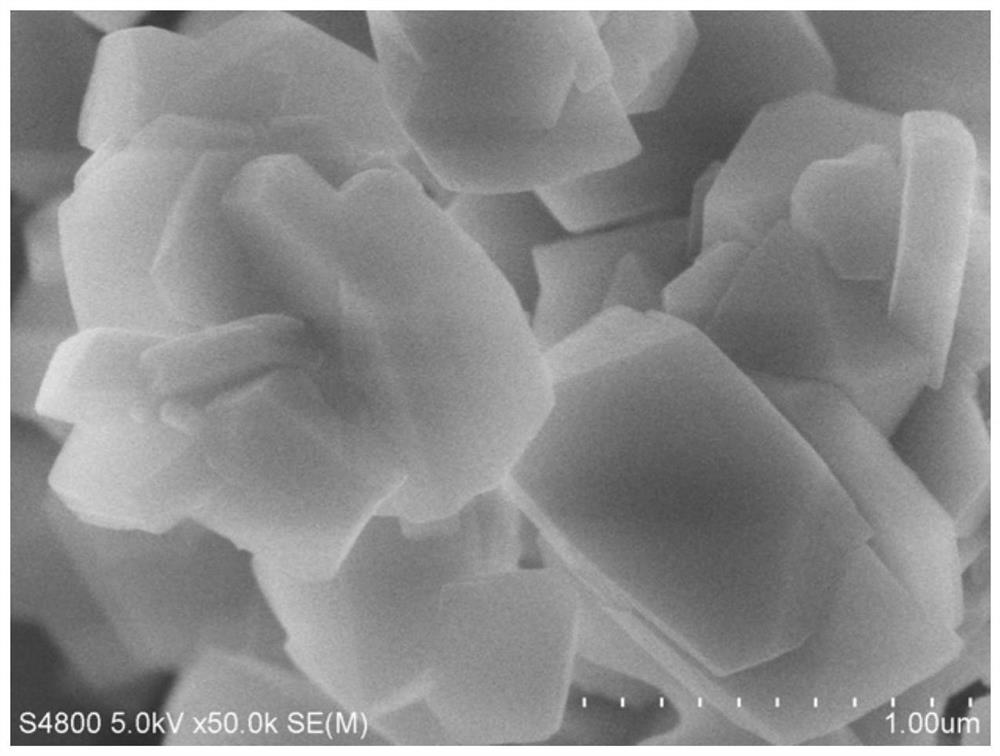

[0050] The scanning electron microscope photo of SAYN-6 has figure 1 The characteristics shown are that the particle size distribution is uniform, the particle size is 1-2 μm, and the N...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com