Catalytic cracking catalyst capable of increasing yield of gasoline and preparation method thereof

A catalytic cracking and catalyst technology, used in catalytic cracking, physical/chemical process catalysts, molecular sieve catalysts, etc., can solve the problems of small B/L acid ratio, small pore volume and high cost, and achieve high heavy oil conversion capacity and high gasoline. Yield, the effect of reducing the conversion of liquefied gas and dry gas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

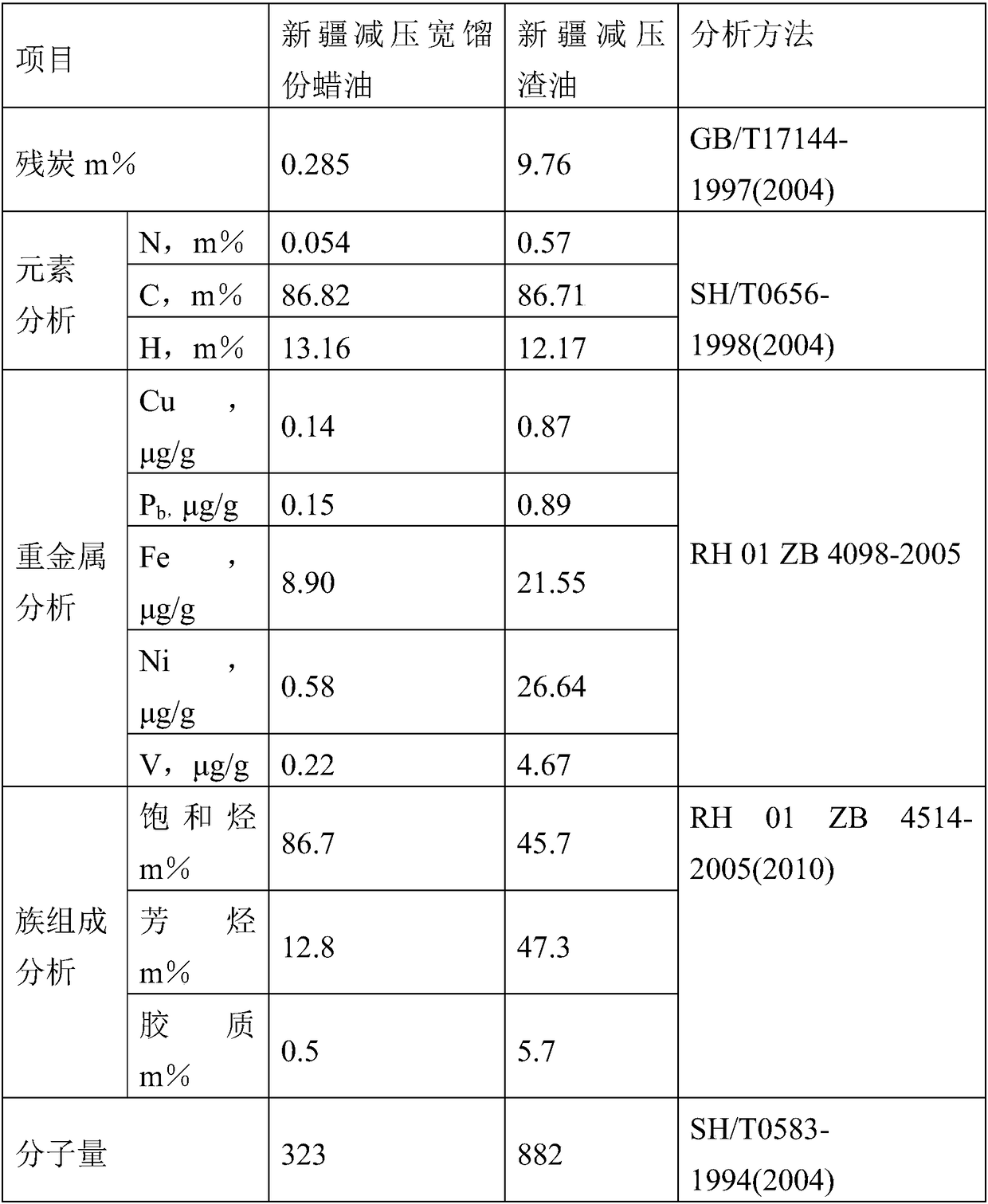

[0036] 1. Raw material

[0037] NaY zeolite directing agent, produced by Lanzhou Petrochemical Company Catalyst Factory;

[0038] Water glass, Si0 2 250g / L, produced by the Catalyst Factory of Lanzhou Petrochemical Company;

[0039] Kaolin, an industrial product of China Kaolinshi Company, with a solid content of 82.7%;

[0040] Pseudoboehmite, produced by Shanxi Aluminum Plant, with a solid content of 60.0%;

[0041] Aluminum sol, containing Al 2 o 3 23.7wt%, produced by the Catalyst Plant of Lanzhou Petrochemical Company;

[0042] RDSY molecular sieve, produced by Lanzhou Petrochemical Company Catalyst Factory, solid content 80.7%, Na 2 O content 1.2 wt%, RE 2 o 3 Content 2.1wt%;

[0043] REY molecular sieve, produced by Lanzhou Petrochemical Company Catalyst Factory, solid content 84.9%, Na 2 O content 1.1 wt%, RE 2 o 3 Content 13.4wt%;

[0044] Other reagents used purchased analytical reagents produced by Sinopharm Chemical Reagent Co., Ltd.

[0045] 2. Main ...

Embodiment 1

[0055] Preparation of Medium and Large Porous Materials Containing Rare Earth

[0056] Take 26.8ml NaY zeolite directing agent and mix with 51.2ml 250g / l water glass evenly, add water to dilute to Si0 2 The concentration is 40g / L (as Si0 2 , the same below), after stirring evenly, neutralize with 6mol / L sulfuric acid solution at 60°C to form a gel for aging, the pH value of the gel is 8, after adding the acid, continue to age at a constant temperature for 1.5h under stirring conditions; after the aging is completed, add 6mol / L sulfuric acid to pH=4, then slowly add 9.9ml 90g / L aluminum chloride solution (A1 2 0 3After the addition, continue to stir for 2 hours; add 10wt% sodium hydroxide solution to adjust the pH value to 7, and age at a constant temperature for 1.5 hours under stirring at 90°C. After the obtained product is filtered and washed, the resulting solid precipitate is ion-exchanged according to ammonium nitrate: solid precipitate (dry basis): water = 1:0.5:8 to ...

Embodiment 2

[0063] Preparation of Medium and Large Porous Materials Containing Rare Earth

[0064] Take 22.23ml of NaY zeolite directing agent and 40.89ml of tetraethyl orthosilicate, mix evenly, add water to dilute to Si0 2 The concentration is 50g / L, after stirring evenly, neutralize with 5mol / L nitric acid solution at 80°C to form a gel for aging, the pH value of the gel is 9, after adding acid, continue aging at constant temperature for 1h under stirring conditions; after aging, add 5mol dropwise / L nitric acid until the pH value = 6, then slowly add 4.76ml 90g / L aluminum nitrate solution under stirring conditions, and continue stirring for 1.5h after the addition; add 10wt% potassium hydroxide solution to adjust the pH value = 9, and stir at 95°C Aging at constant temperature for 2h. After the resulting product is filtered and washed, the resulting solid precipitate is ion-exchanged to remove sodium ions according to ammonium nitrate:solid precipitate (dry basis):water=1:0.7:9, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com