Hydrated alumina containing metallic element and method for preparing the same

A technology of hydrated alumina and metal elements, applied in chemical instruments and methods, catalyst activation/preparation, metal/metal oxide/metal hydroxide catalysts, etc. The sulfur reduction performance needs to be improved to achieve the effect of low gasoline sulfur content, high heavy oil conversion capacity, and large average pore size

Active Publication Date: 2010-12-01

CHINA PETROLEUM & CHEM CORP +1

View PDF5 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The hydrated alumina with the above-mentioned pseudo-boehmite structure provided by the prior art can be used as a matrix material, but when these uniformly dispersed hydrated alumina additives are used to prepare catalysts such as catalytic cracking, the heavy oil cracking performance of the catalyst, Light oil yield and sulfur reduction performance need to be improved

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

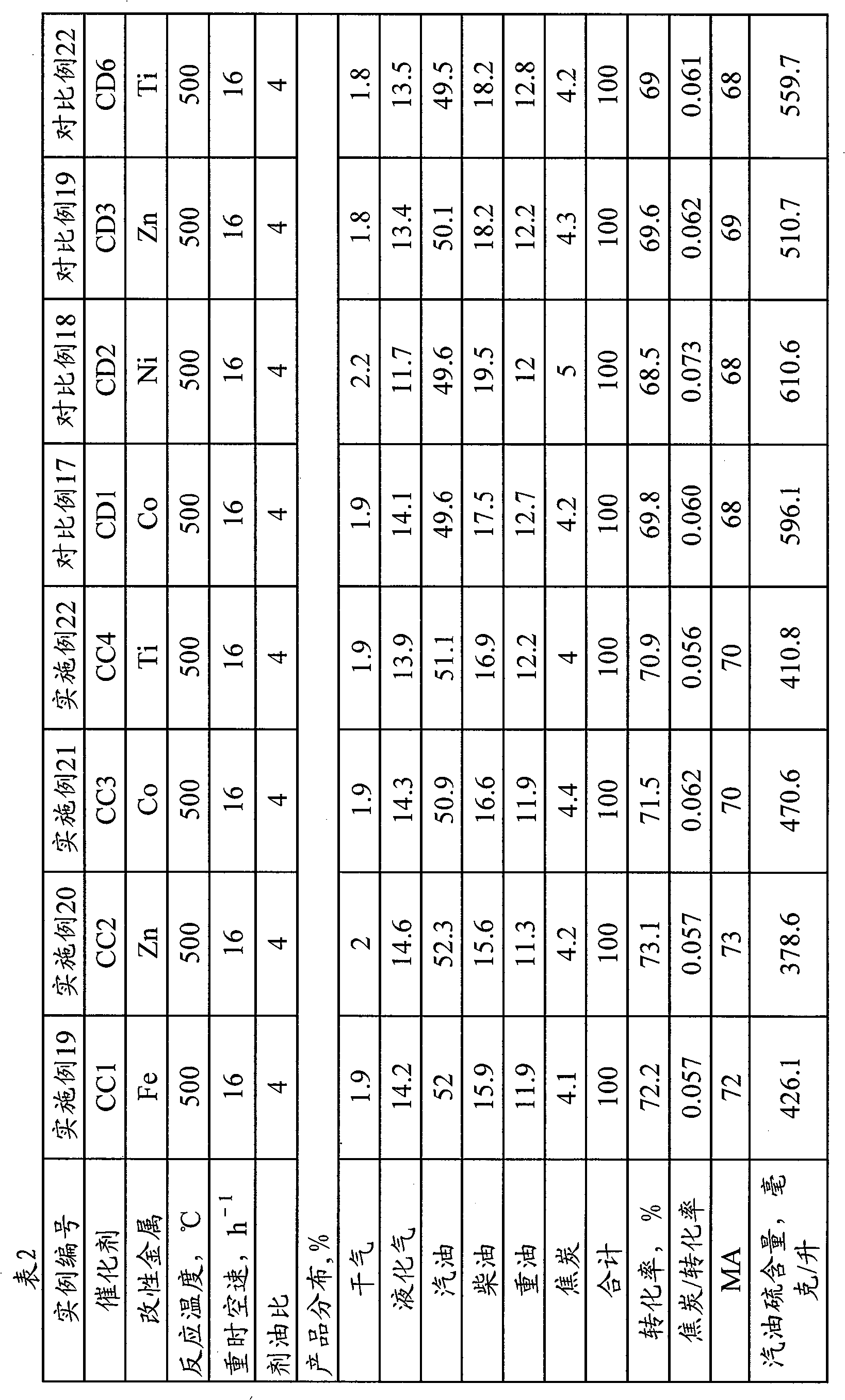

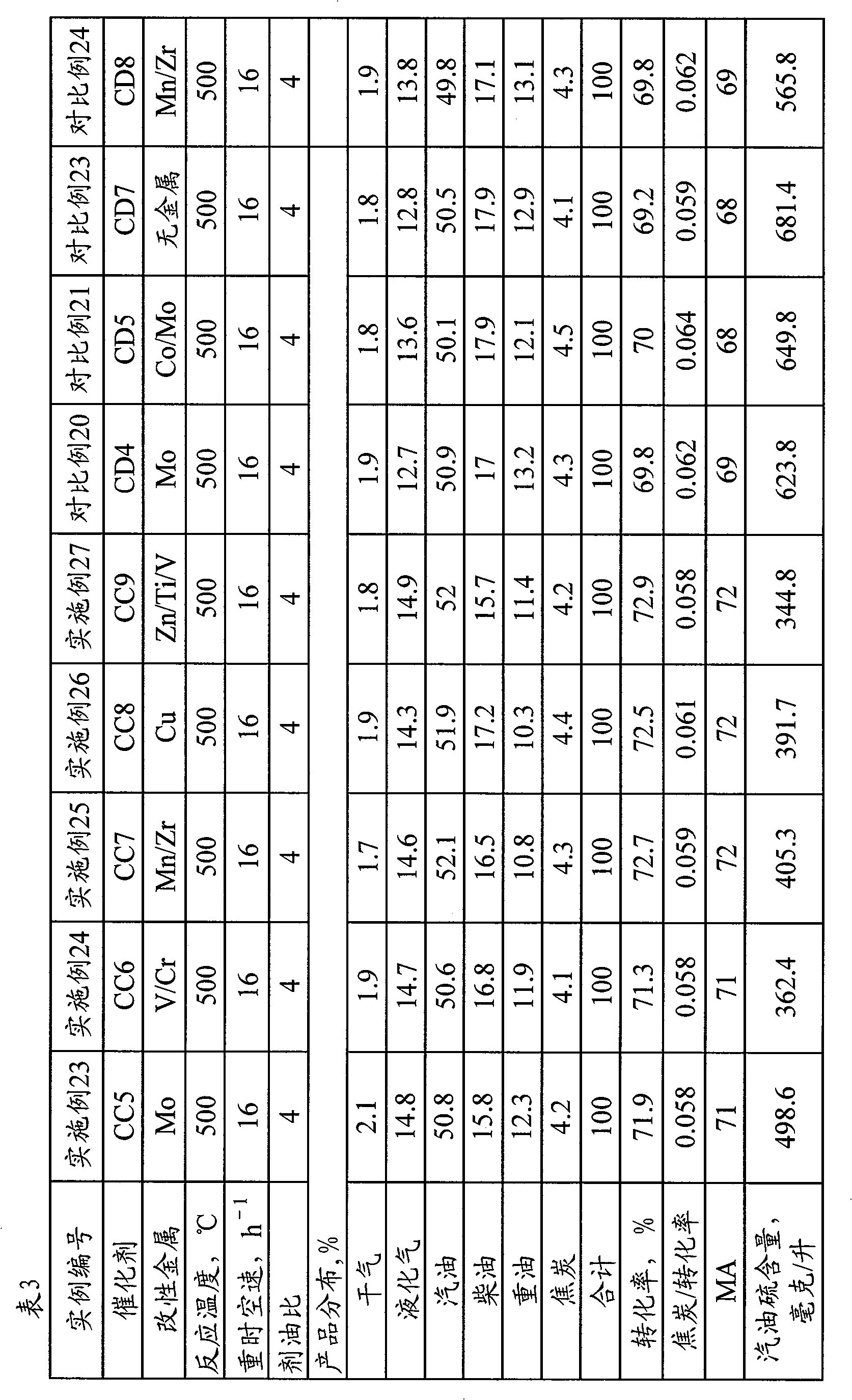

Login to View More Abstract

A hydrated alumina containing metal elements and the preparation method is provided. The alumina after being roasted contains 50-99 percent by weight of alumina and one species or a plurality of species of metal oxide selected from Cu, Fe, V, Cr, Mn, Zr, Zn, Co, Ti and Mo, wherein firstly, the content of the Cu, Fe, V, Cr, Mn and Zr is 0.5-50 percent; secondly, the content of the Zn, Co, Ti and Mo is 10- 50 percent. The catalyst adopting the hydrated alumina preparation provided by the present invention has higher heavy oil conversion capability and lower gasoline sulfur content.

Description

A kind of hydrated aluminum oxide containing metal element and preparation method thereof technical field The invention relates to hydrated alumina and a preparation method thereof, in particular to a hydrated alumina with a metal additive-containing pseudo-boehmite structure and a preparation method thereof. Background technique Pseudo-boehmite (α-Al2O3.nH2O, n=1.4~2.0) is a boehmite type with incomplete crystallization, also known as colloidal boehmite or pseudo-boehmite, formed by thermal decomposition γ-Al2O3 has a good mesopore structure, specific surface area, and very active chemical properties, and is widely used in chemical and petroleum refining and other fields. Pseudo-boehmite and its processed products are porous substances, which have both molecular sieve effect and adsorption properties, and are used as adsorbents, desiccants, catalysts and carriers. It has good thermal and hydrothermal stability under catalytic cracking operating conditions, and is a high-...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): B01J23/75B01J21/04B01J23/72B01J23/745B01J23/34B01J23/26B01J23/06B01J37/04C10G11/04

Inventor 于善青朱玉霞田辉平许明德张万虹

Owner CHINA PETROLEUM & CHEM CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com