Large-section cable laying method

A technology for cable laying and large cross-section, applied in cable laying equipment and other directions, can solve the problems of high construction cost, large volume and weight of conveyor, inconvenient operation, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Below in conjunction with accompanying drawing and embodiment the present invention is described further as follows:

[0023] A method for laying cables with large cross-sections, comprising the following steps:

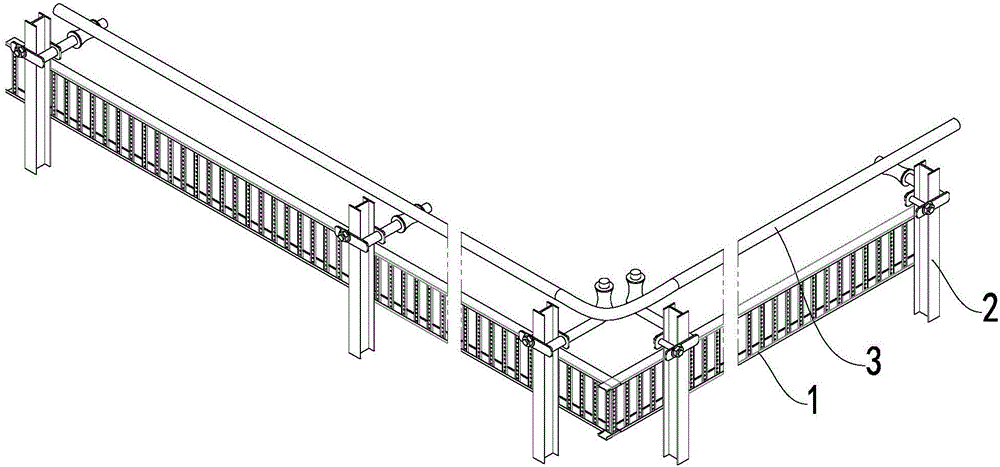

[0024] 1), use the column 2 to lay the cable tray 1 inside the comprehensive pipe gallery;

[0025] 2) Install a cable reel at the starting point of the cable tray 1, and install an electric winch or hoist at the end of the cable tray 1;

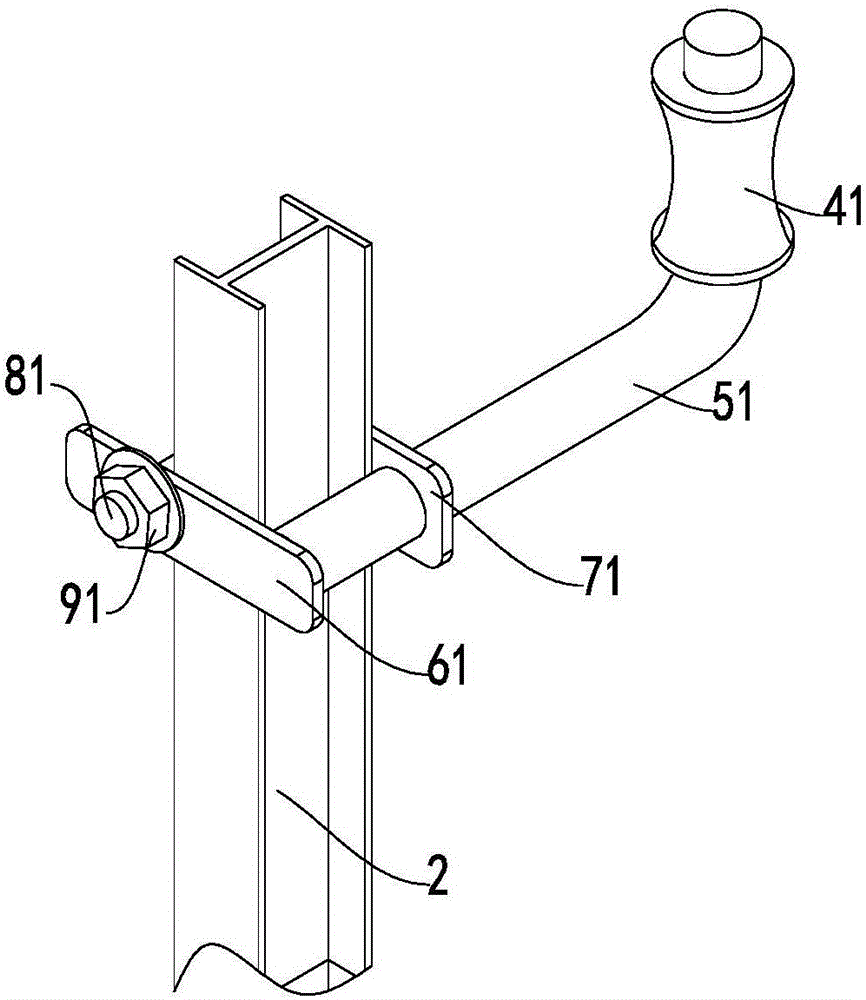

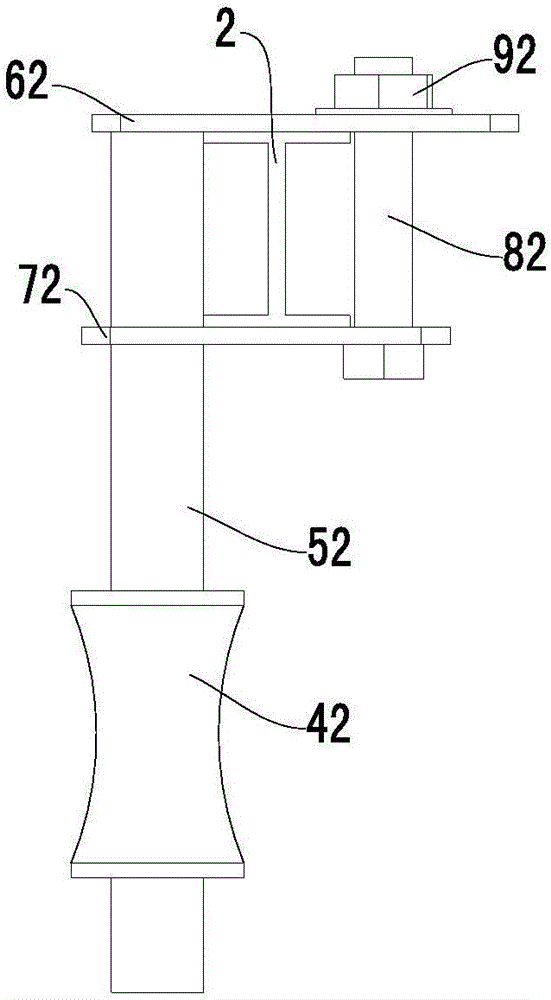

[0026] 3), making the roller device, the first type of roller device located at the corner of the cable tray 1 and the second type of roller device located outside the corner of the cable tray 1 and uniformly distributed along the extending direction of the cable tray 1; A type of roller device includes a first roller 41 located above the cable tray 1 and a first bracket, the first roller 41 is detachably mounted on the column 2 at the corner of the cable tray 1 through the first bracket, the first roller 41 Arranged in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com