Method for constructing urban utility tunnel

A technology of pipe gallery and integrated pipe gallery, applied in construction, underwater structures, infrastructure engineering and other directions, can solve the problems of labor and material cost increase, long construction period, etc., to reduce repetitive frame and formwork construction, easy to Operation and time saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

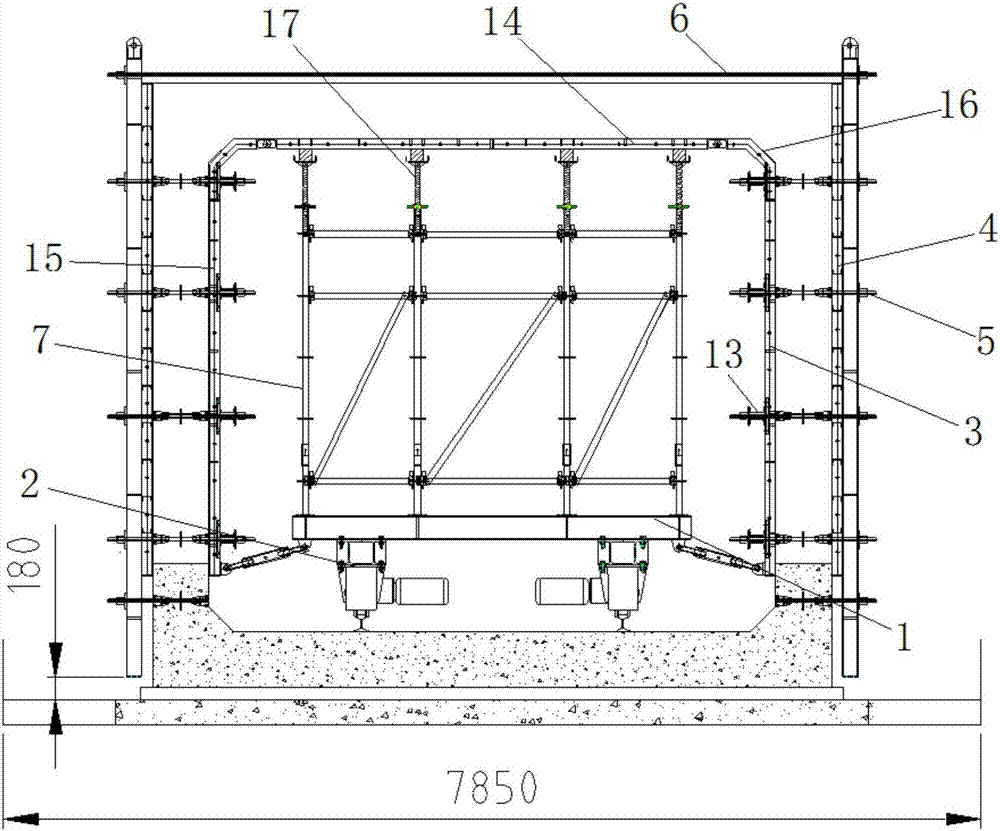

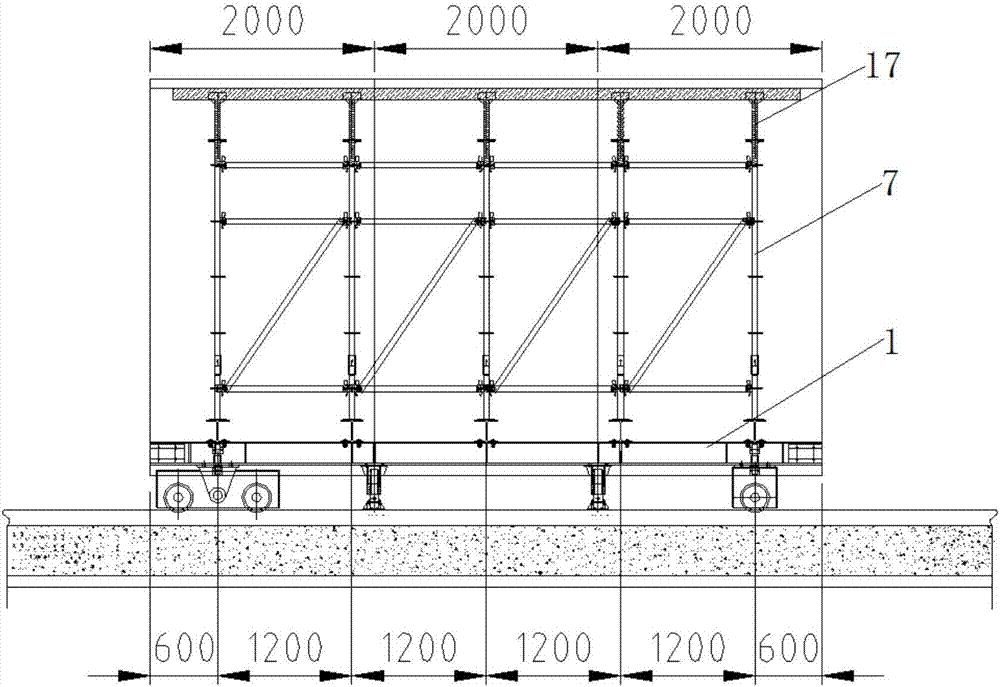

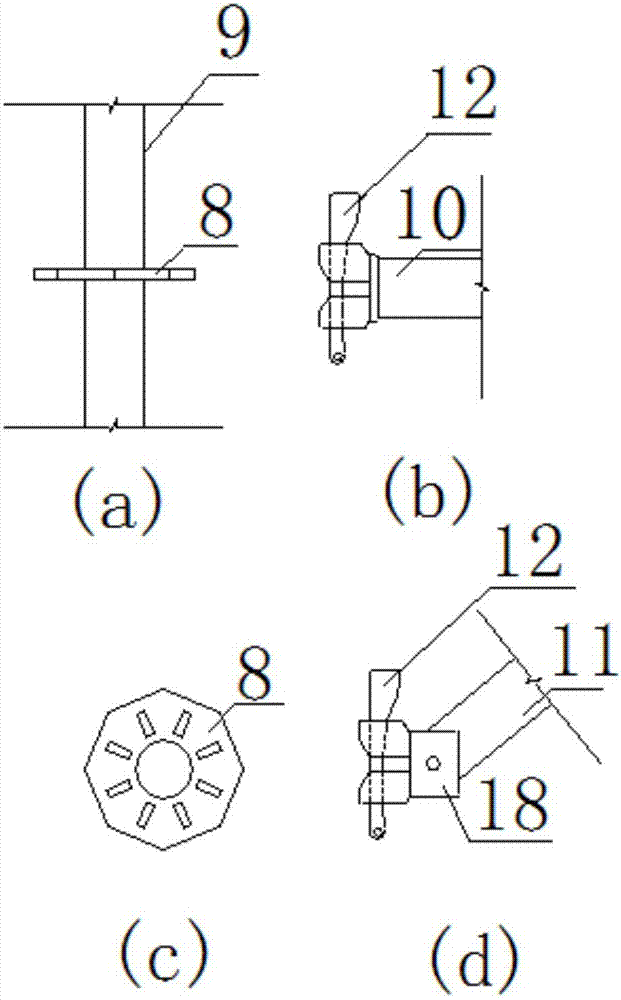

[0028] Embodiment: A method for constructing an urban pipe gallery according to the present invention is constructed by using a mobile formwork structure of a comprehensive pipe gallery, such as figure 1 and figure 2 As shown, the mobile formwork of the comprehensive pipe gallery is set on the track on the bottom plate of the pipe gallery, including the moving part of the mobile formwork, the supporting structure and the formwork; the walking part of the mobile formwork includes a walking truss 1 and a walking motor 2 The stressed support structure is fixed on the walking truss 1 by bolts; the formwork includes an inner formwork 3 and an outer formwork 4, and the formwork is made of a stainless steel composite plate material, and the inner formwork 3 and the outer formwork 4 are both Made of stainless steel composite plate material, the inner template 3 is composed of an upper inner mold top mold 14, inner mold side molds 15 on both sides and an inner mold corner connecting t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com