Structure of utility tunnel and construction method

A technology of integrated pipe gallery and construction method, applied to underwater structures, infrastructure engineering, artificial islands, etc., can solve the problems of high construction cost, long construction period, difficult lifting and transportation, etc., and achieve mechanization and industrialization, Easy hoisting and transportation, saving labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0055] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

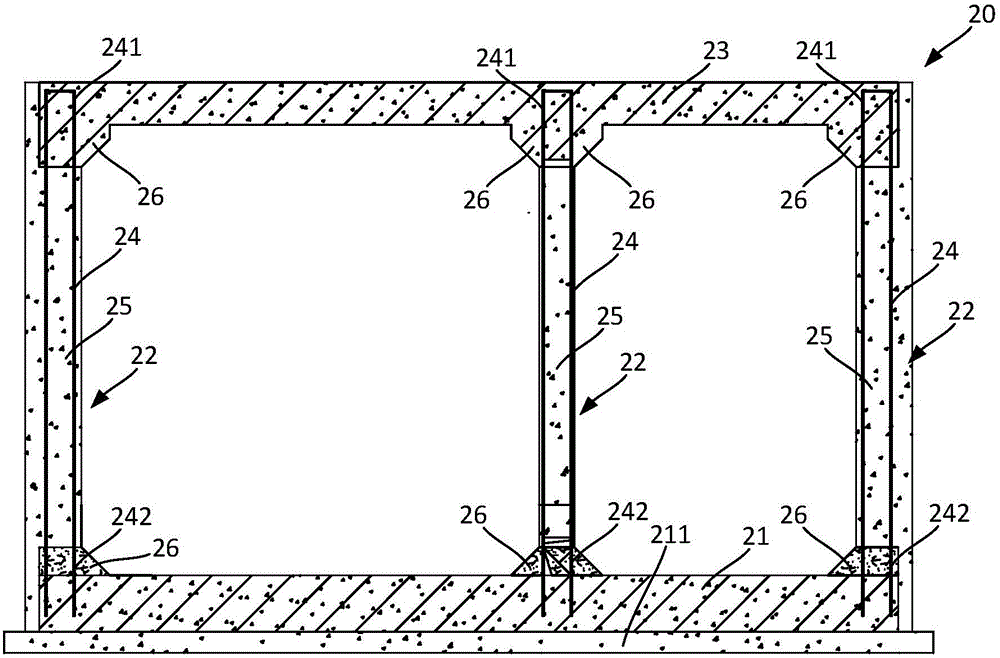

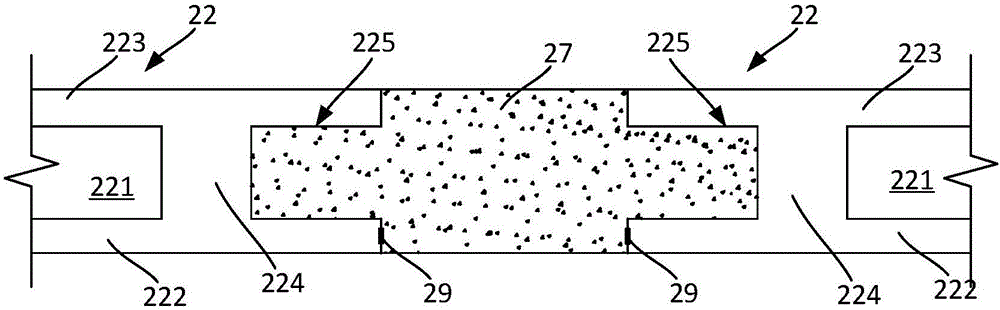

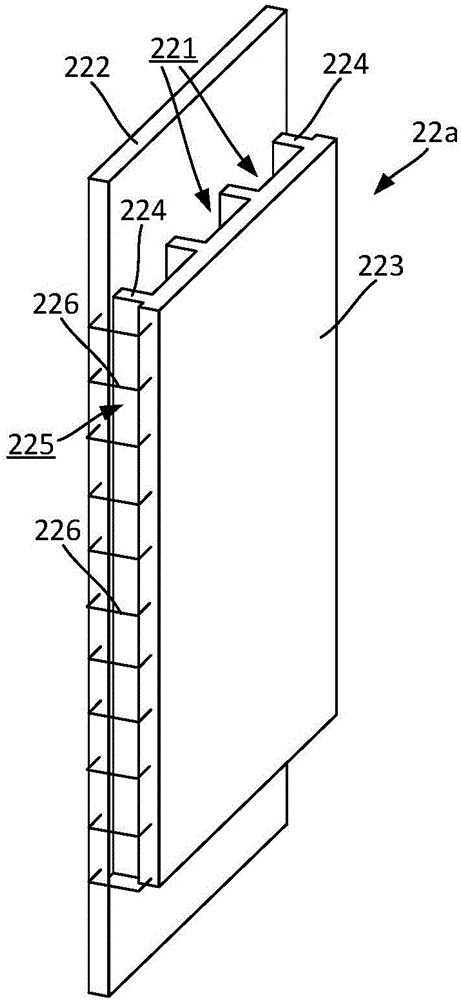

[0056] refer to figure 1 and Figure 5 , The invention provides a structure and construction method of an underground comprehensive utility gallery, the structure type of which belongs to the sandwich wall panel mixed prefabricated structure. The concrete underground comprehensive pipe gallery for the prefabricated structure can realize mechanization and industrialization to the greatest extent, can save the formwork cost and corresponding labor cost of all wall panels, and can save the labor cost of wall panel steel bar binding. Compared with traditional craft construction, the efficiency is higher The increase is more than 5 times, and the on-site wet operation is reduced by more than 80%. All sandwich prefabricated wall panels and supporting installation templates are processed in the factory at one time. The structure and construction met...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com