Pre-assembled single-compartment municipal tunnel and construction method thereof

A prefabricated assembly and comprehensive pipe gallery technology, which is applied in artificial islands, water conservancy projects, infrastructure projects, etc., can solve the problems of difficult quality control and long construction period of cast-in-place structures, and achieve low cost and easy control of project quality. The effect of improving structural safety and durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

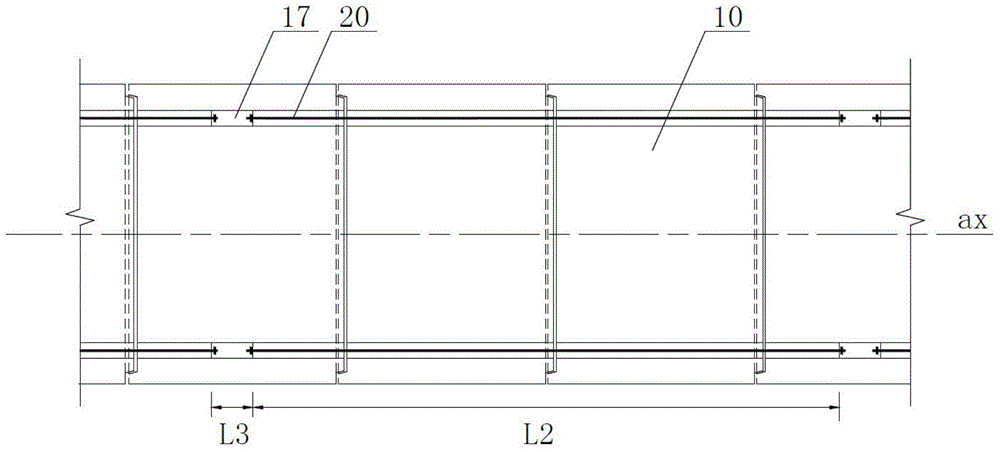

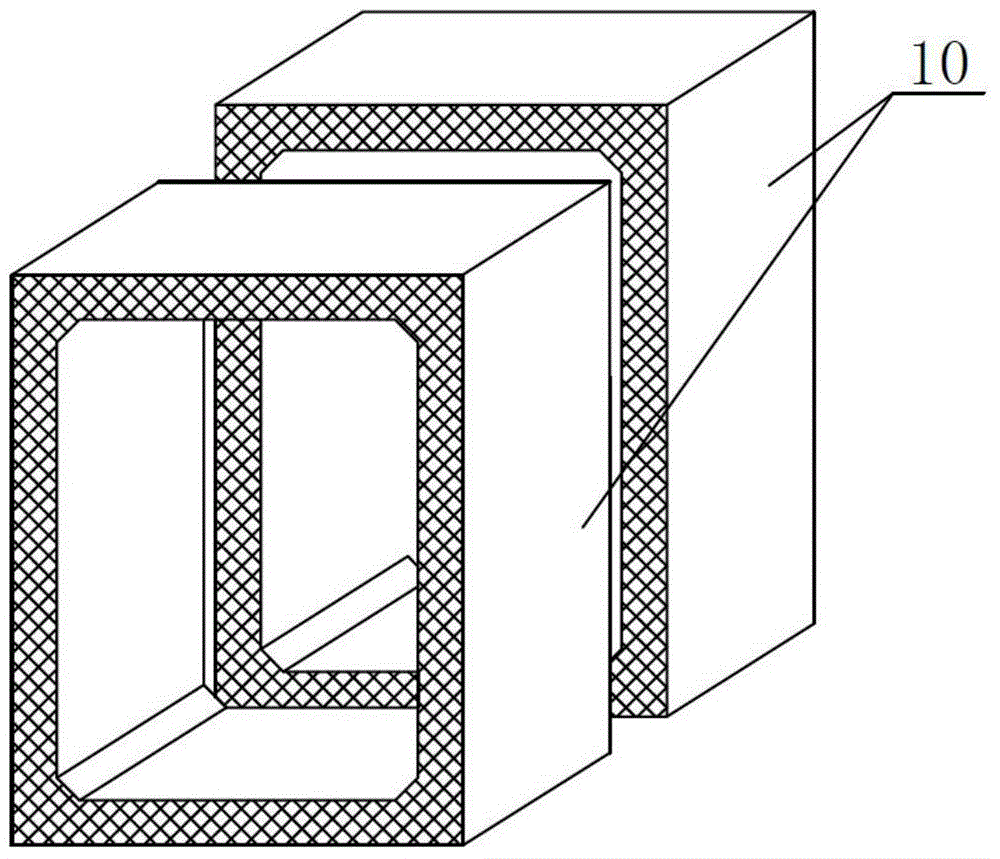

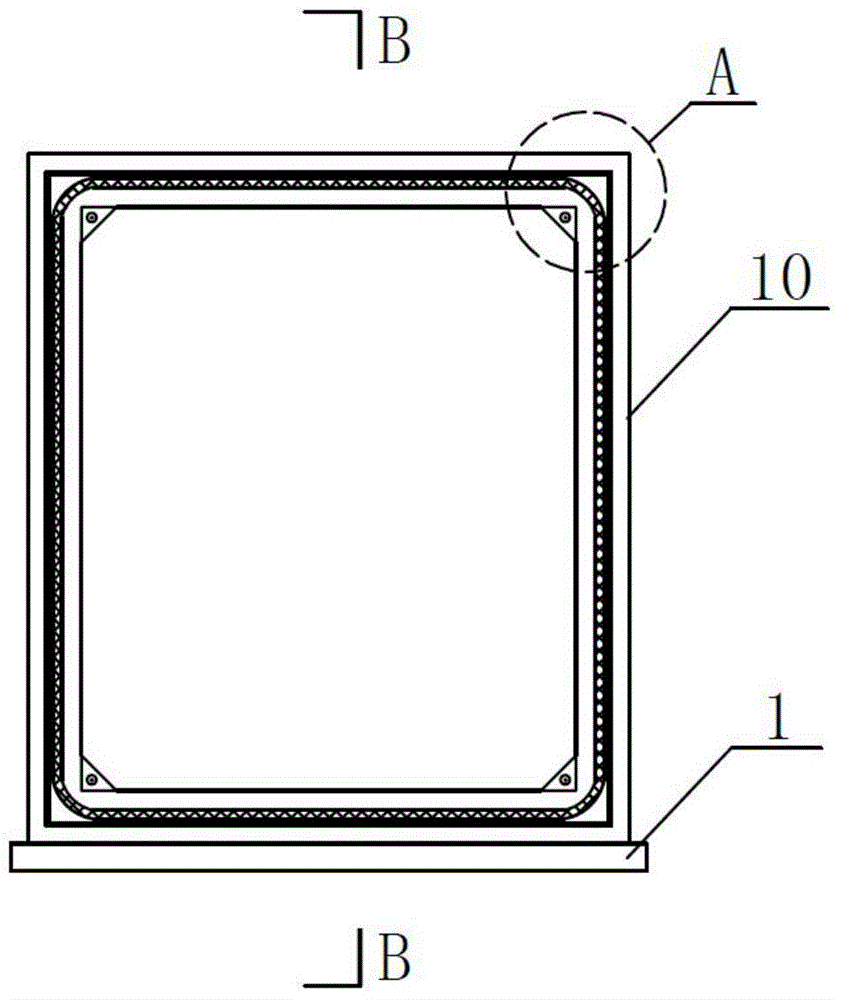

[0040] Example 1: Combining Figure 1 to Figure 6Illustrate the prefabricated and assembled single-cabin municipal comprehensive pipe gallery of the present invention (for brevity of description, referred to as comprehensive pipe gallery in the text), this embodiment takes the construction of a comprehensive pipe gallery with a rectangular longitudinal section as an example, and the utilization rate of the comprehensive pipe gallery with a rectangular section Higher, so the application range is wider. It is assembled by a number of prefabricated pipe joints 10 arranged on the concrete cushion 1 and having longitudinal joints. At right angles, the stress concentration is relatively serious. In order to improve the stress conditions, a number of supports 11 with through holes 11a are pre-buried at the four corners of the inner wall edge, and the pipe joint connectors 20 with built-in prestressed steel bars 10 The ax direction of the axis runs through several supports 11 in sequ...

Embodiment 2

[0049] Embodiment 2: Combination Figure 7 to Figure 11 Illustrates that the prefabricated assembled single-chamber municipal comprehensive pipe gallery of the present invention is different from the first embodiment in that, in order to facilitate the manufacture, transportation and installation of the large-section prefabricated pipe section 10, each prefabricated pipe section 10 is composed of two horizontal joints The upper and lower prefabricated sections 10a, 10b are butted and assembled. The above-mentioned transverse joint is a concave-convex structure formed by the mutual engagement of the transverse protrusion and the transverse notch. When the upper and lower prefabricated sections 10a, 10b are butted and assembled, the horizontal The protrusion and the transverse notch can squeeze each other tightly, and through the meshing action of the transverse protrusion and the transverse notch, shear force and axial force can be better transmitted and good waterproof performa...

Embodiment 3

[0053] Example Three: Combining Figure 1 to Figure 6 Illustrate the construction method of the prefabricated single-chamber municipal comprehensive pipe gallery of the present invention. This embodiment takes the construction of the comprehensive pipe gallery described in Embodiment 1 as an example. The specific steps are as follows:

[0054] S101: Carry out structural calculations based on the geological conditions and surrounding environment of the comprehensive utility gallery. The structural calculation includes three aspects, namely load calculation, internal force calculation and section design. Among them, the load calculation mainly considers the static load on the comprehensive utility gallery , live loads, special loads, and accidental loads such as earthquakes; the internal force calculation is mainly to select a reasonable calculation diagram, preliminarily assume the size of the section, and calculate the structure's anti-floating and design bending moment, shear ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com