Modified acrylate spray membrane waterproofing material and preparation method thereof

A technology of acrylate and spray film waterproofing, which is applied in the direction of coating, etc., and can solve problems such as easy cracking of the coating film

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

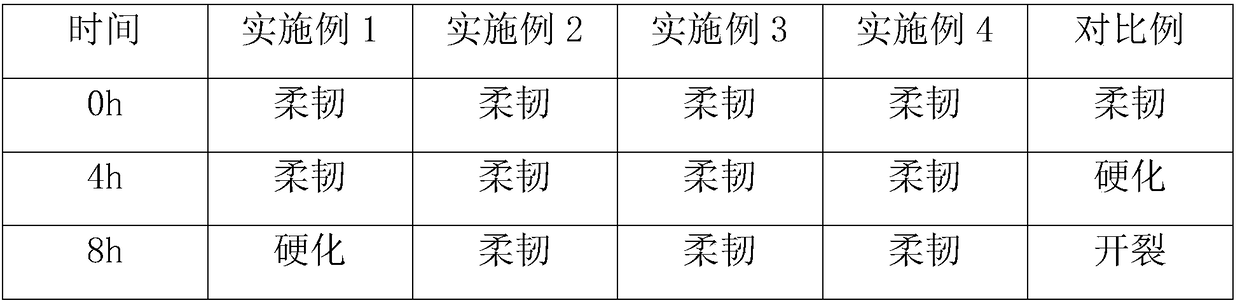

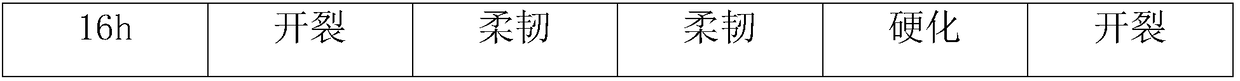

Examples

preparation example Construction

[0020] Another aspect of the present invention provides a kind of preparation method of above-mentioned modified acrylate spray film waterproofing material, and this preparation method comprises: mixing acrylate aqueous solution, water-based emulsion and optional pigment and / or auxiliary agent uniformly, divide into A, Two parts of B are mixed with oxidizing agent and reducing agent respectively. The "mixing with the oxidizing agent and the reducing agent separately" means that one part is mixed with the oxidizing agent, and the other part is mixed with the reducing agent.

[0021] According to the present invention, preferably, the ratio of the A part to the B part is 0.01:1-1:0.01.

[0022] As a preferred solution, all raw materials for preparing the modified acrylate spray film waterproofing material of the present invention can be obtained commercially.

Embodiment 1

[0026] In parts by weight, the raw materials for preparing the waterproof material of this embodiment are: 100 parts of calcium acrylate aqueous solution with a mass concentration of 45%, 20 parts of styrene-acrylic emulsion, 1 part of sodium persulfate, 0.5 part of ferrous sulfate, heavy carbonic acid 30 parts of calcium, 1992 parts of defoamer B.

[0027] Concrete preparation steps are as follows:

[0028] Mix calcium acrylate aqueous solution, styrene-acrylic emulsion, powder and additives, disperse at high speed, stir evenly, divide into two parts A and B according to the ratio of 1:1, and add sodium persulfate and ferrous sulfate respectively.

Embodiment 2

[0030] In parts by weight, the raw materials for preparing the waterproof material of this embodiment are: 100 parts of magnesium acrylate aqueous solution with a mass concentration of 45%, 50 parts of pure acrylic emulsion, 2 parts of ammonium persulfate, 3 parts of sodium bisulfite, light carbonic acid Calcium 50 parts, defoamer DF-88682 parts, anti-sedimentation agent TN601 3 parts.

[0031] Concrete preparation steps are as follows:

[0032] Mix magnesium acrylate aqueous solution, pure acrylic emulsion, powder and additives, disperse at high speed, stir evenly, divide into two parts A and B according to the ratio of 1:1, and add ammonium persulfate and sodium bisulfite respectively.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com