Rolling mill equipment installing method

A technology for equipment installation and rolling mill, applied in the direction of metal rolling stand, metal rolling mill stand, metal processing equipment, etc., can solve the problems of not meeting product quality requirements, rolling mill base, rolling mill stand installation accuracy level, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

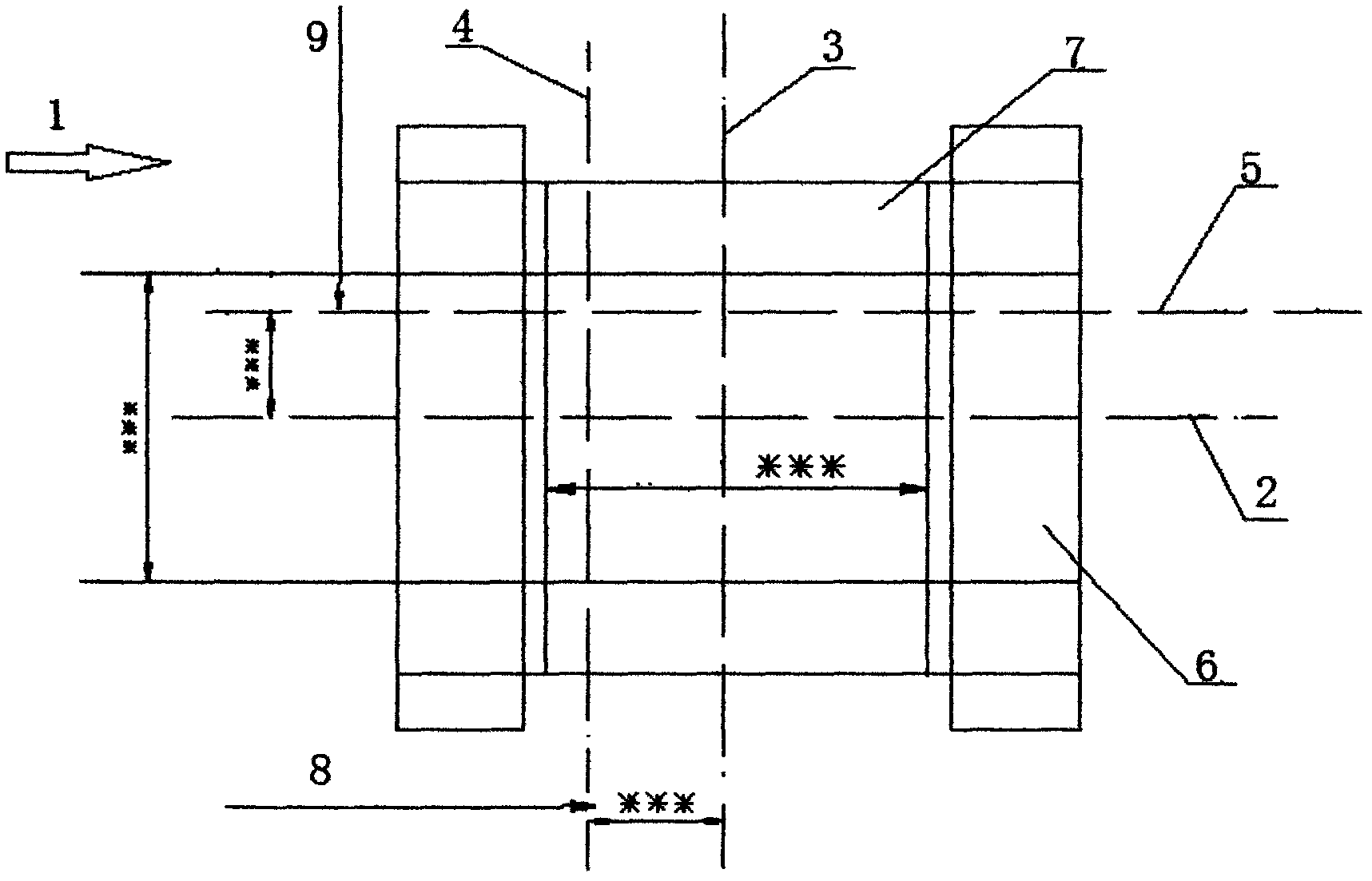

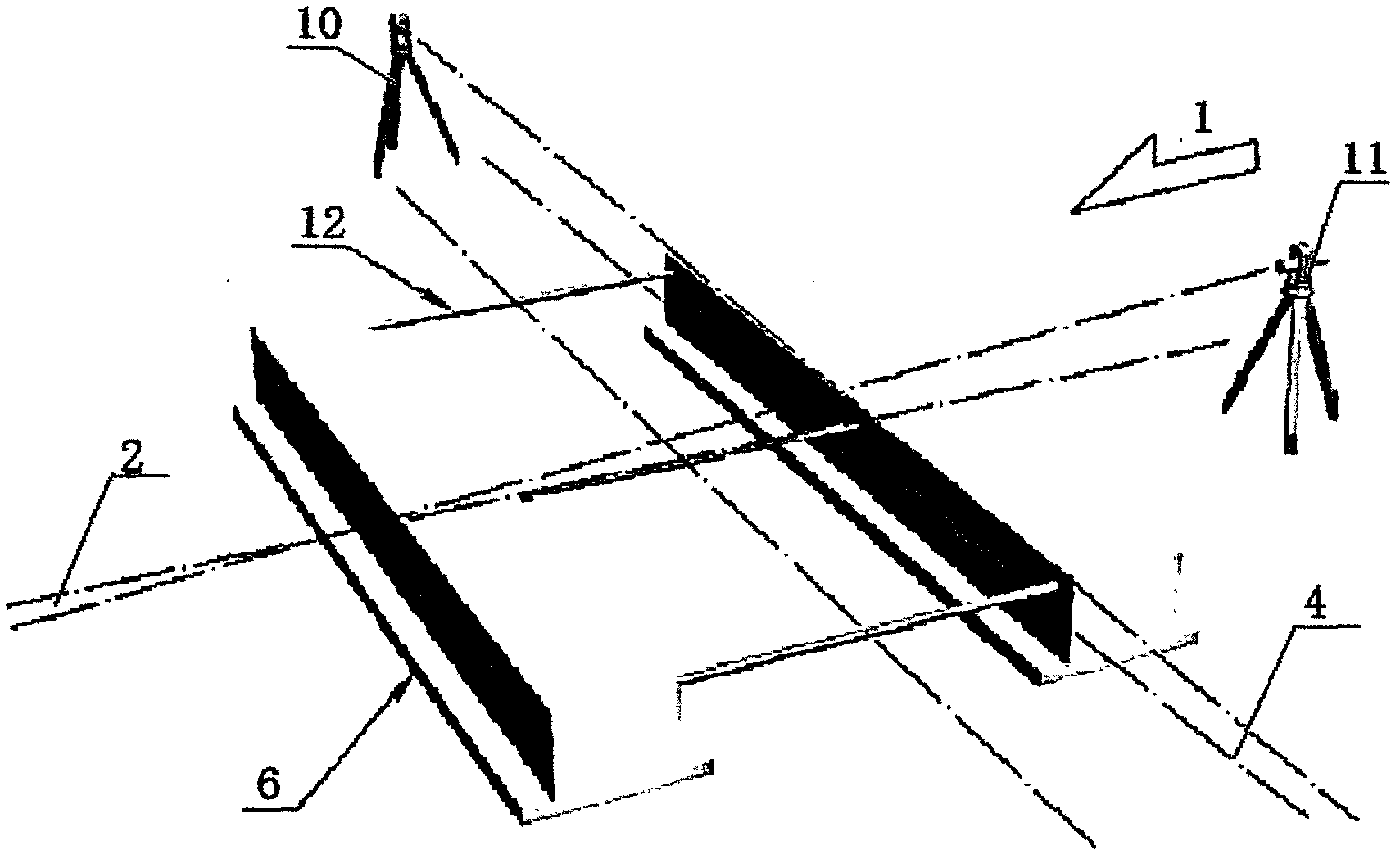

[0014] Such as figure 1 As shown, according to the center line (3) of the rolling mill frame and the size of the drawing, calculate the distance from the center line (3) of the frame to the entrance (1) frame base (6) and the joint surface of the archway, and make a line with the center line of the frame (3 ) parallel to the auxiliary center line of the rolling mill base (4).

[0015] According to the centerline (3) of the rolling mill stand and the size of the drawing, calculate the dimension (8) from the centerline of the stand (3) to the sliding plate surface of the stand window, and make its auxiliary parallel centerline and the distance along the rolling centerline (2) to the drive The dimension (9) of the inner surface of the side frame is used as the auxiliary parallel centerline (5) of the rolling mill frame.

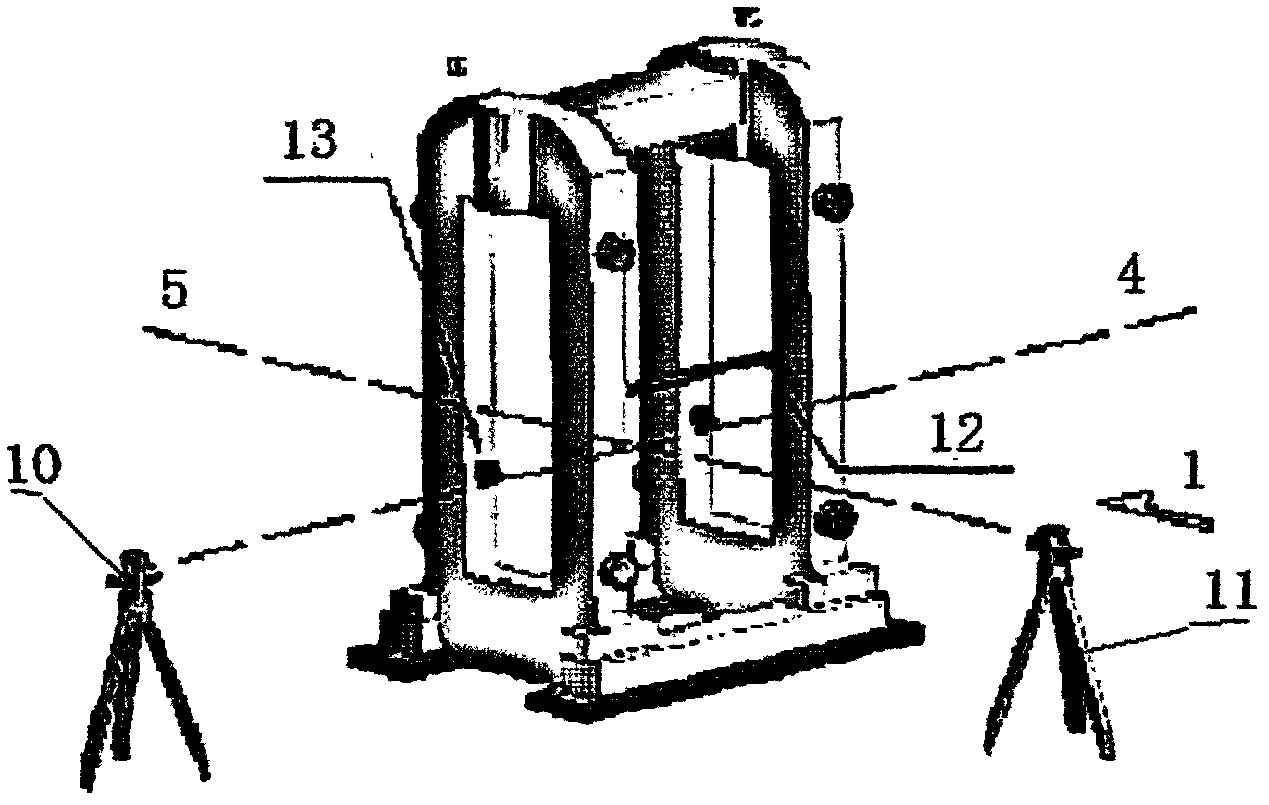

[0016] The rolling mill base (6) is the most important part in equipment installation, and it directly affects the installation accuracy of the top equipment, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com