Concrete pouring construction method for underground gallery

A construction method and concrete technology, applied in the field of concrete pouring, can solve the problems of high cost of construction materials and difficult control of construction quality, and achieve the effects of shortening the construction period, reducing the construction cost and increasing the turnover rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

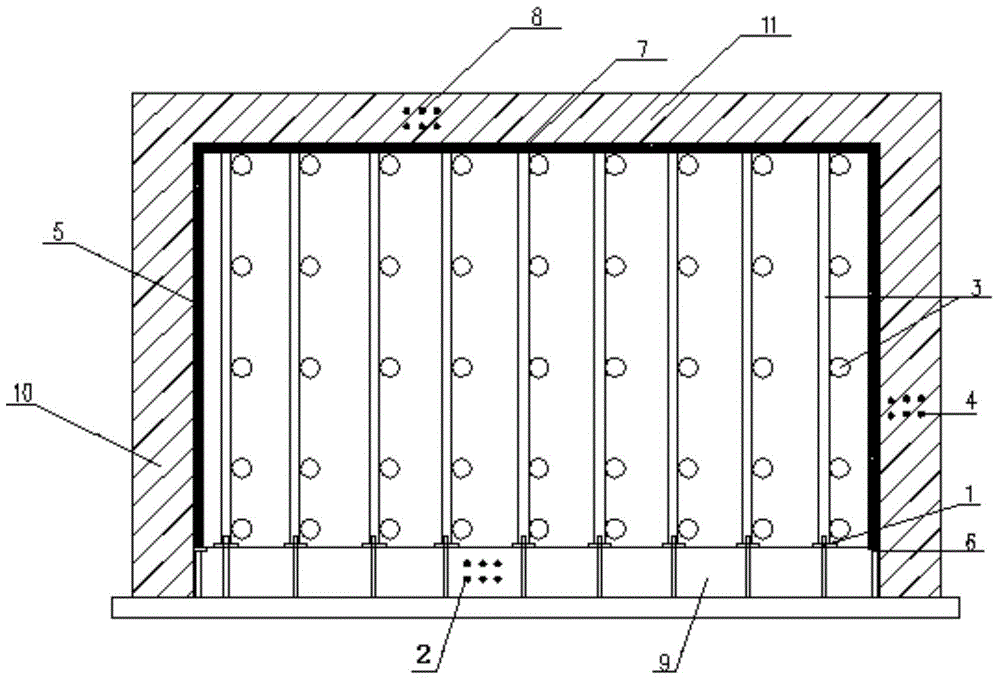

[0021] The present invention will be described in detail below in conjunction with the accompanying drawings.

[0022] The concrete pouring construction method of the underground corridor comprises the following steps:

[0023] (1) Project positioning and setting out, earthwork excavation, cushion concrete construction;

[0024] (2) Bottom plate reinforcement 2 binding, welding bracket. After the binding of the steel bars on the bottom plate is completed, the bracket 1 is arranged on the steel bars on the bottom plate according to the spacing requirements of the vertical poles of the scaffolding. The vertical steel bar of the bracket 1 is welded on the steel bar 2 of the bottom plate with the remaining steel bar waste of Φ20, and the welding length on the steel bar of Φ20 is 100mm The Φ14 steel bar is used as the support point for the vertical pole.

[0025] (3) After the side wall reinforcement 4 is bound, weld the reinforcement bracket 6 on the inner side of the junction b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com