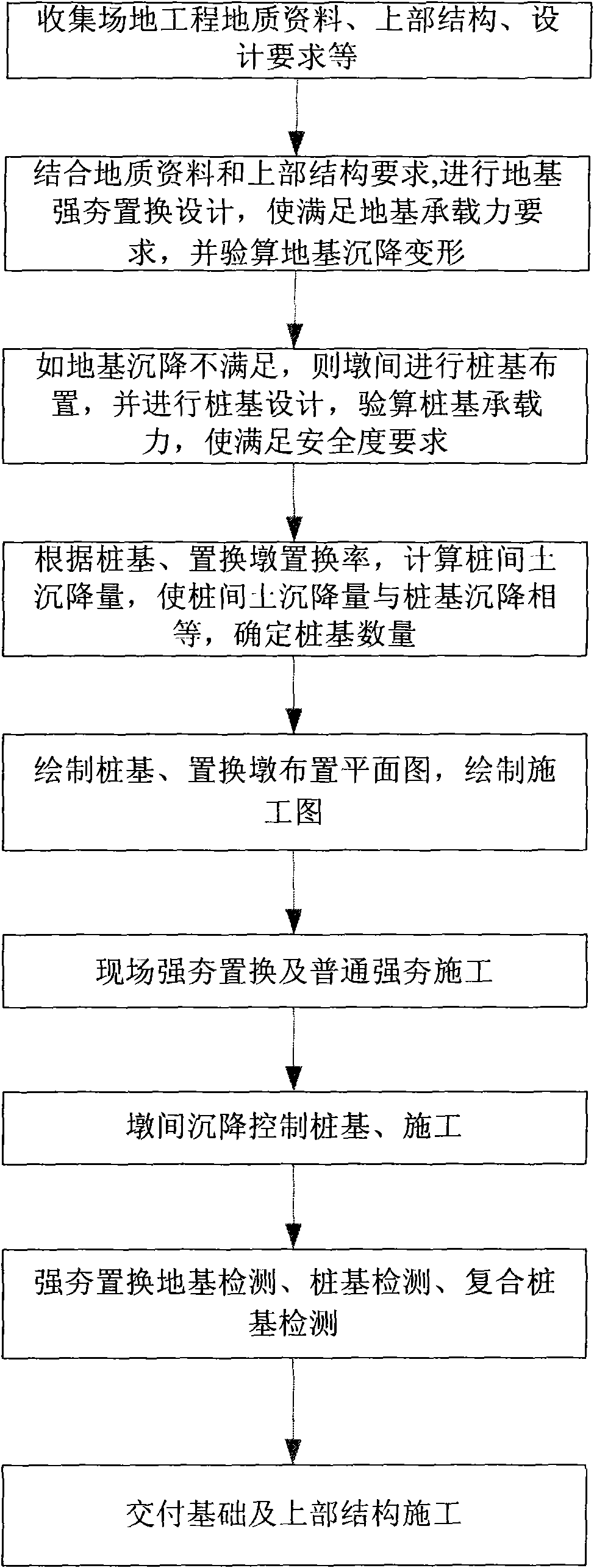

Method for processing long-pile short-pier composite foundation

A treatment method and technology for composite foundations, applied in sheet pile walls, foundation structure engineering, soil protection, etc., can solve the problems of low foundation bearing capacity, unfinished self-weight consolidation, etc., to speed up the construction period, save the cost, and save the cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below in conjunction with the embodiments shown in the accompanying drawings.

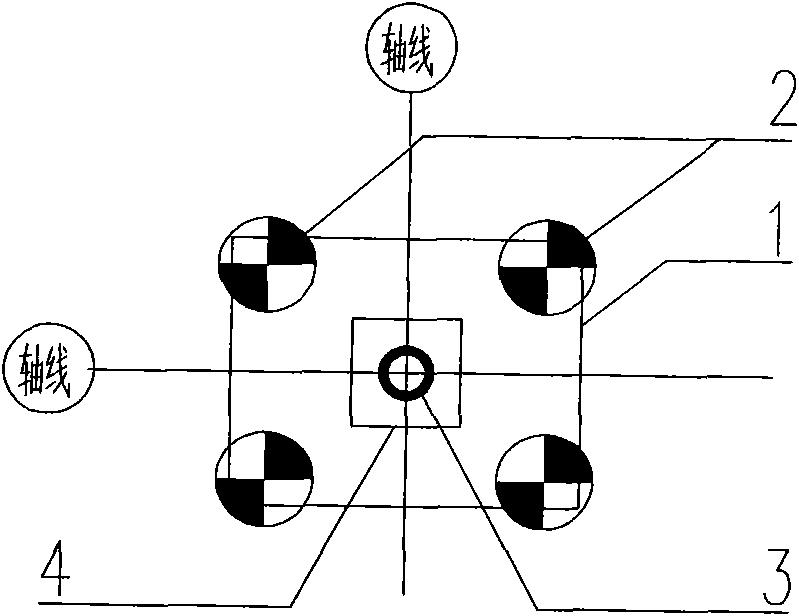

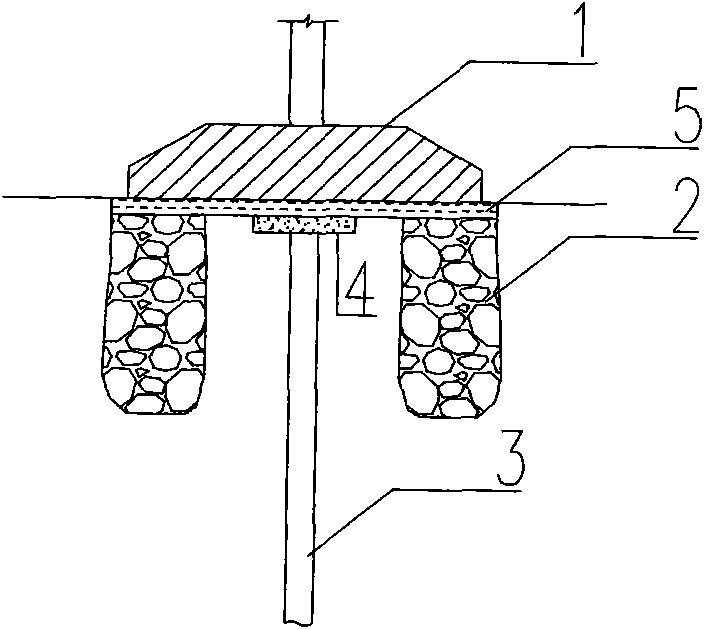

[0034] Figure 2 to Figure 7 It is a relative schematic diagram of settlement control pile and dynamic tamping or dynamic tamping replacement mop point method and foundation of the present invention. In specific implementation, according to the type of foundation, different tamping point arrangement methods or their combinations can be used for foundation treatment design.

[0035] For independent foundations, the figure 2 or Figure 4 2 to 4 replacement piers 2 are constructed symmetrically within the scope of the independent foundation 1 by dynamic compaction or dynamic compaction, and settlement control piles 3 are arranged between the piers; Figure 6In the arrangement shown, the replacement piers 2 and the settlement control piles 3 are alternately arranged in a rectangular or quincunx shape. The foundation bearing capacity requiremen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com