Large-span self-anchored suspension bridge hoisting construction method and temporary tower-girder anchoring device

A construction method and temporary anchor technology, which are applied in the directions of bridges, bridge construction, erection/assembly of bridges, etc., can solve the problems of low thrust resistance of side span buttresses, large construction risks, limited horizontal force, etc., and achieve a simple and reliable construction process. , The effect of reducing risk factors and fast construction progress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

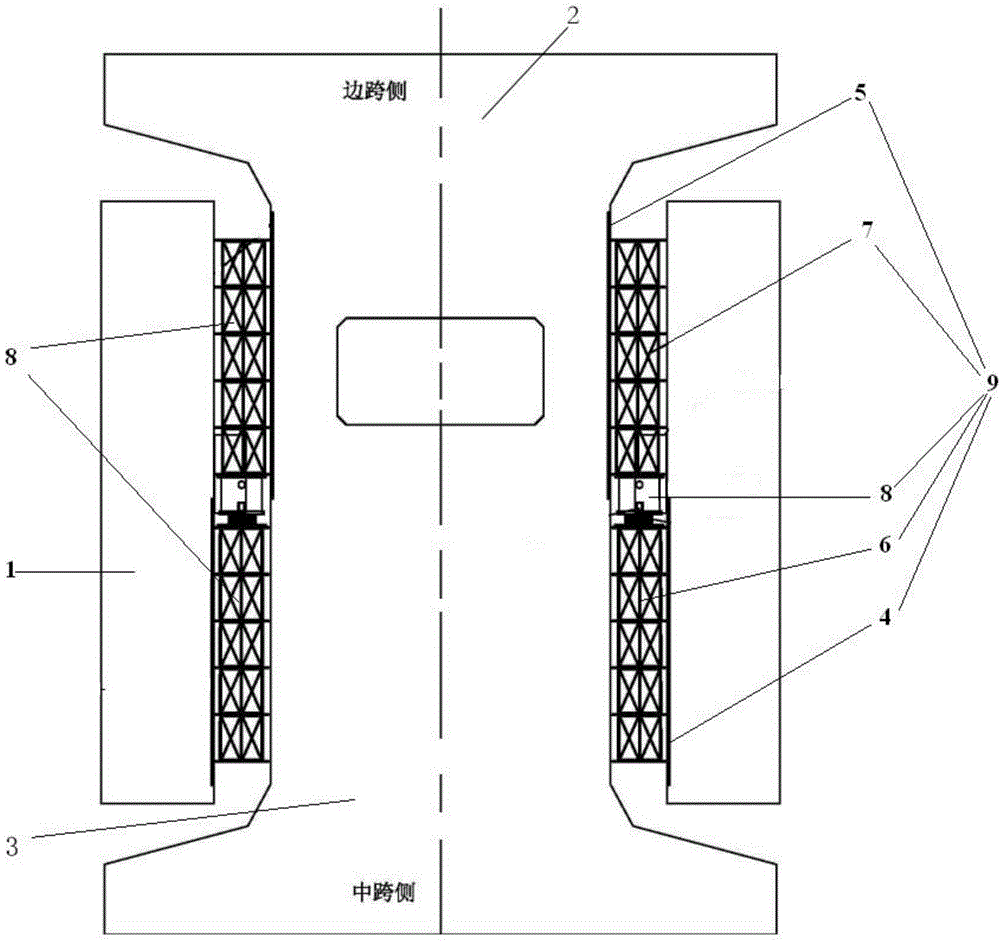

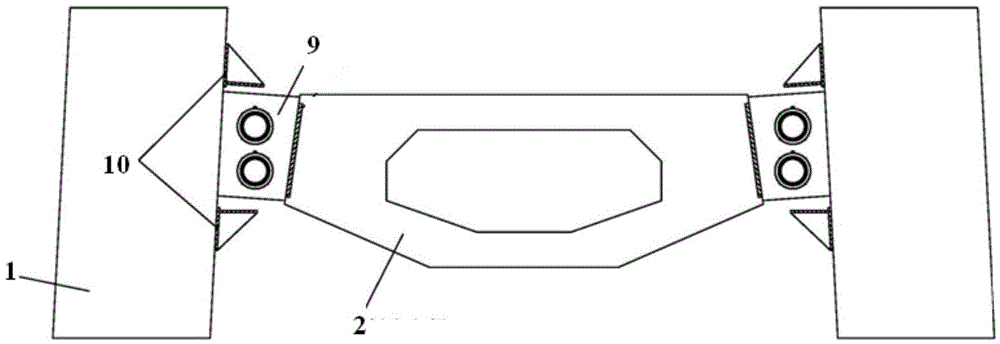

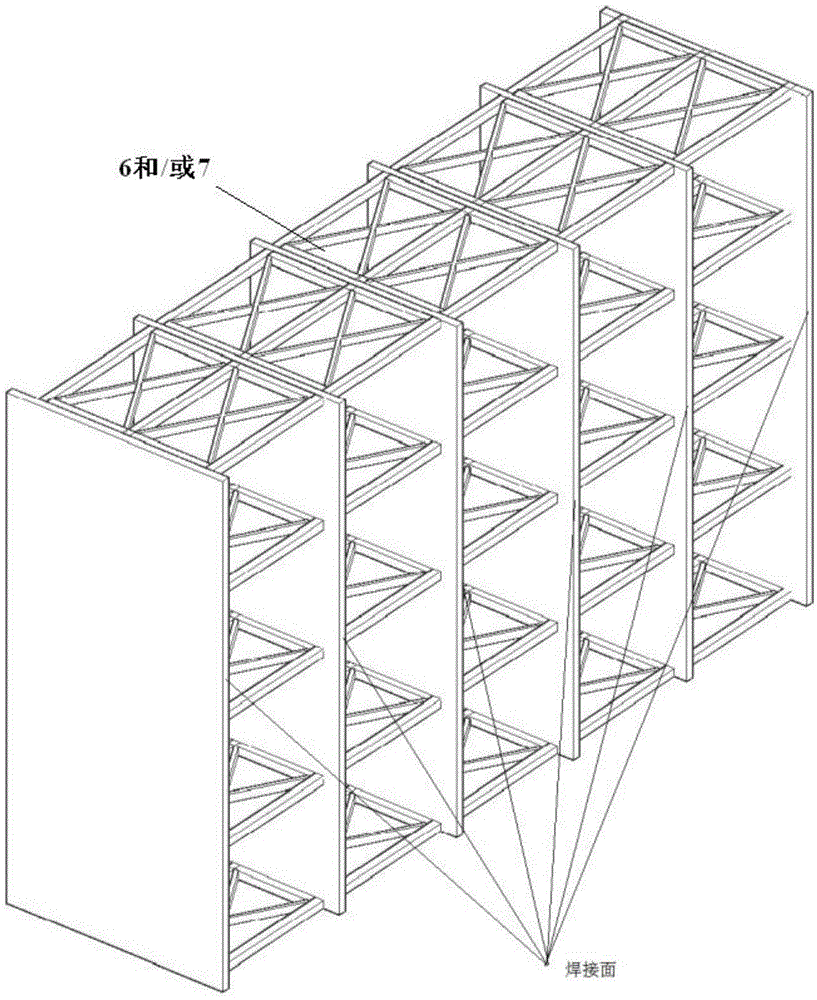

[0051] This embodiment provides a kind of tower beam temporary anchoring device, including the first pre-embedded steel plate 4 pre-set on the side wall of the bridge tower 1 near the side of the middle span, and pre-set on the side wall of the main girder 2 of the side span near the side of the side span The second embedded steel plate 5, the first embedded steel plate 4 is fixedly installed with the first grid frame 6, the second embedded steel plate 5 is fixedly installed with the second grid frame 7, the first grid frame 6 and the second The axial centerlines of the two grid frames 7 are on the same axis parallel to the side span main beam 2 vehicle traveling direction, so that an end face of the first grid frame 6 and an end face of the second grid frame 7 are arranged oppositely, Form the action surface of the force transmission brace 8;

[0052] The two opposite end surfaces of the first grid frame 6 and the second grid frame 7 are supported by force transmission braces...

Embodiment 2

[0060] This embodiment provides a hoisting construction method for a large-span self-anchored suspension bridge using the tower beam temporary anchoring device described in Embodiment 1. During the construction process, the side span main beam 2 is supported by the tower beam temporary anchoring device. The horizontal force is transmitted to the bridge tower 1. This construction method is suitable for the double-tower three-span self-anchored suspension bridge structure in which the side-span main girder 2 is a concrete main girder and the mid-span main girder 3 is a steel main girder. It specifically includes the following steps:

[0061] Step 1, carry out foundation treatment to the foundation of the bridge tower 1 of bridge, construction pier foundation 11, bridge tower 1 and side-span bridge pier 12, such as Image 6 shown;

[0062] Step 2, set up side-span temporary pier or support 13, cast-in-situ concrete main girder on side-span temporary pier or support 13, stretch pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com