Lifting installation system for buckling restrained supporting member and construction method thereof

A buckling restraint and support member technology, applied in building construction, building material processing, construction, etc., can solve the problems of irregular operation, different construction methods, high engineering cost, achieve obvious economic benefits, save manpower and material resources, Guarantee the effect of construction progress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

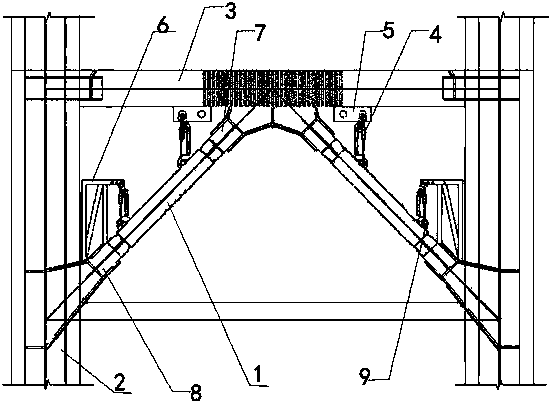

[0027] The present invention does not limit the structure of the buckling-constrained support member 1. The buckling-constrained support member involved in this embodiment uses a steel material with a yield strength of 235 MPa and a grade of Q235B as the core plate, and re-inspects the material. The re-inspection requirements are : The yield strength ratio of the core material should not be greater than 0.8, the elongation should be greater than 30%, and it should have 27J impact toughness work at room temperature. The material of all gusset plates connected to buckling constrained brace member 1 is Q345B.

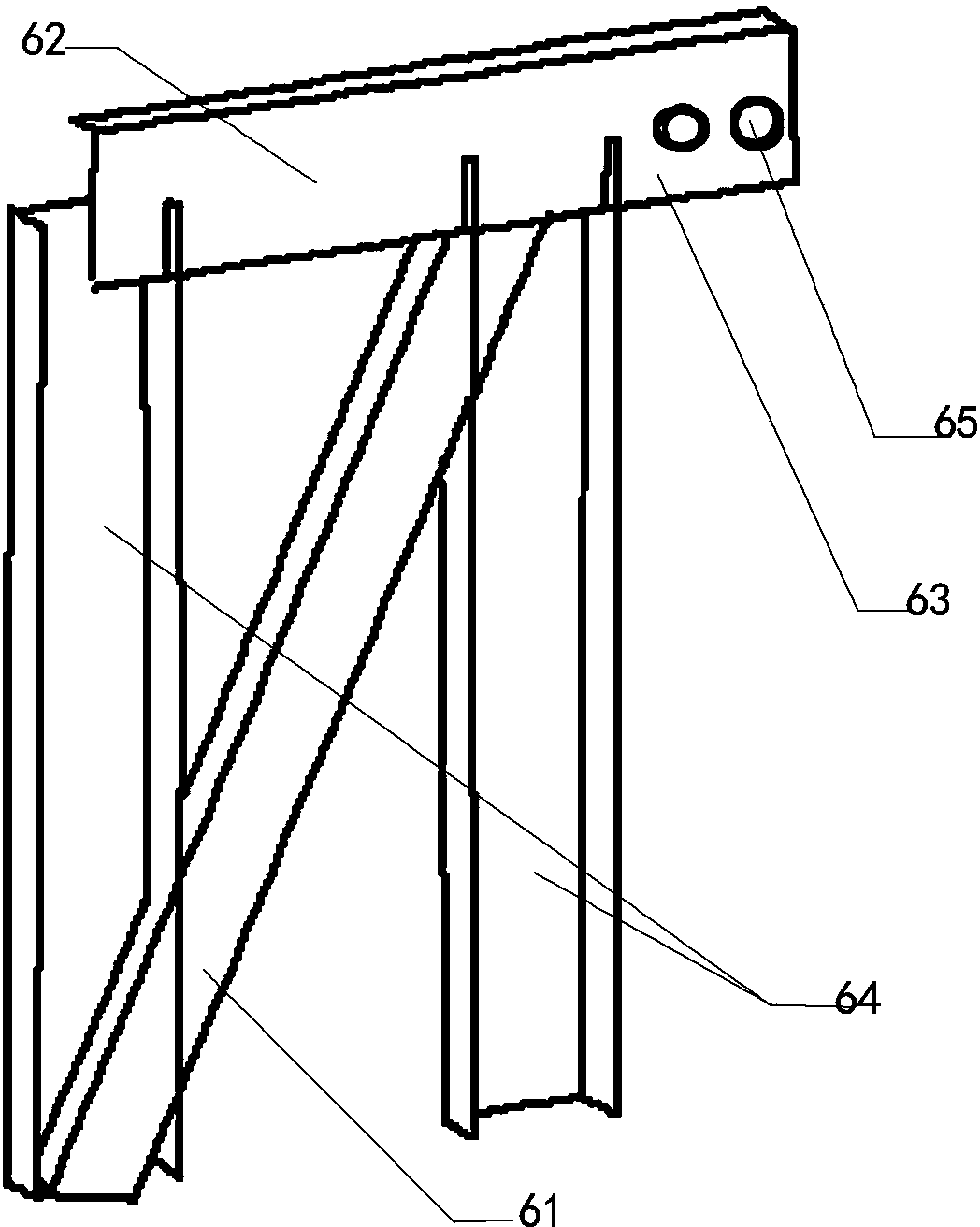

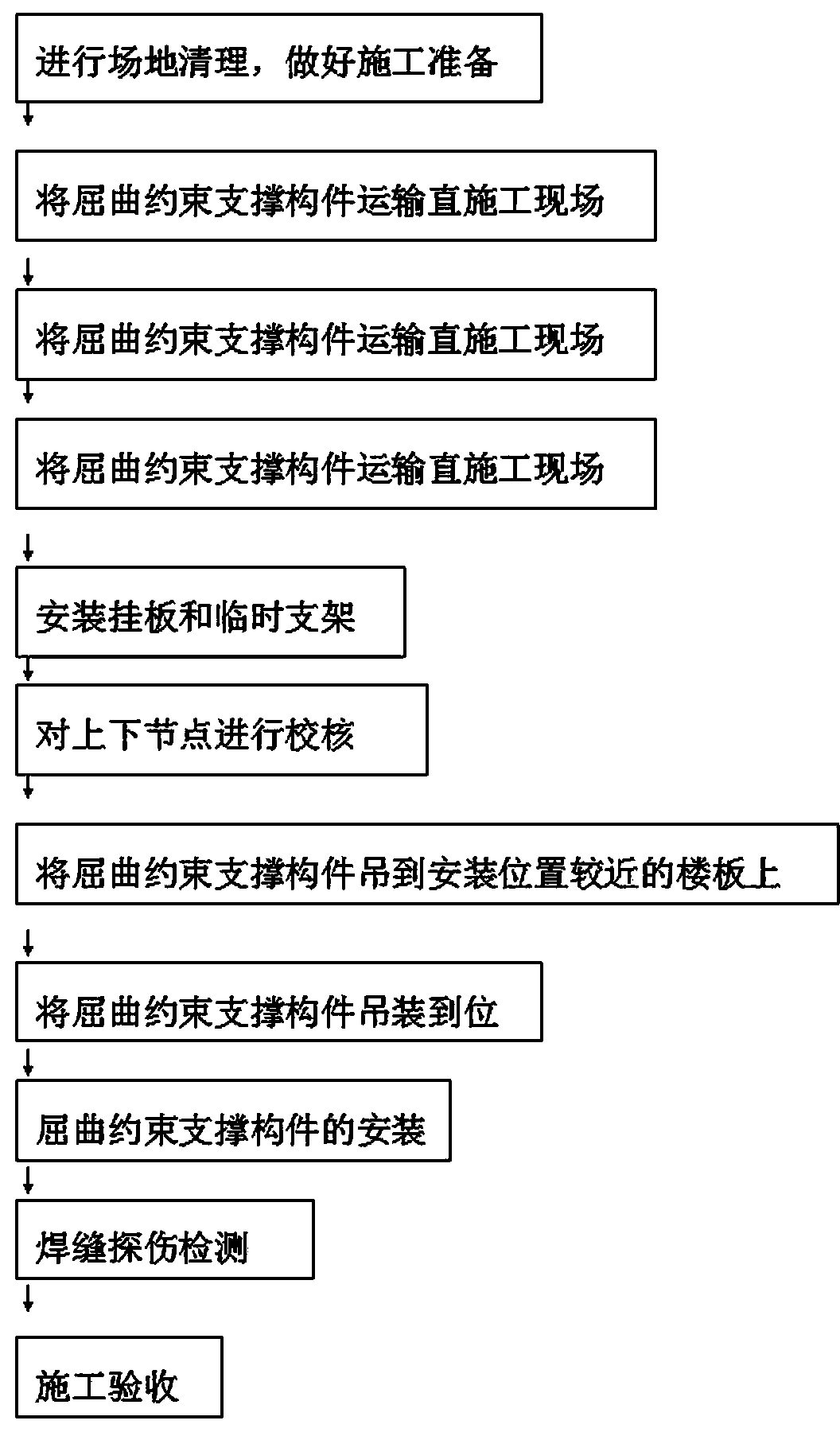

[0028] Such as figure 1 and figure 2 As shown, a lifting and installation system for buckling restraint support members includes the completed beam 3 and support column 2, the inverted chain 4 for lifting the buckling restraint support member 1, a car crane, and a fall arrester for safety protection. As well as movable scaffolding, etc., the buckling restraint support m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com