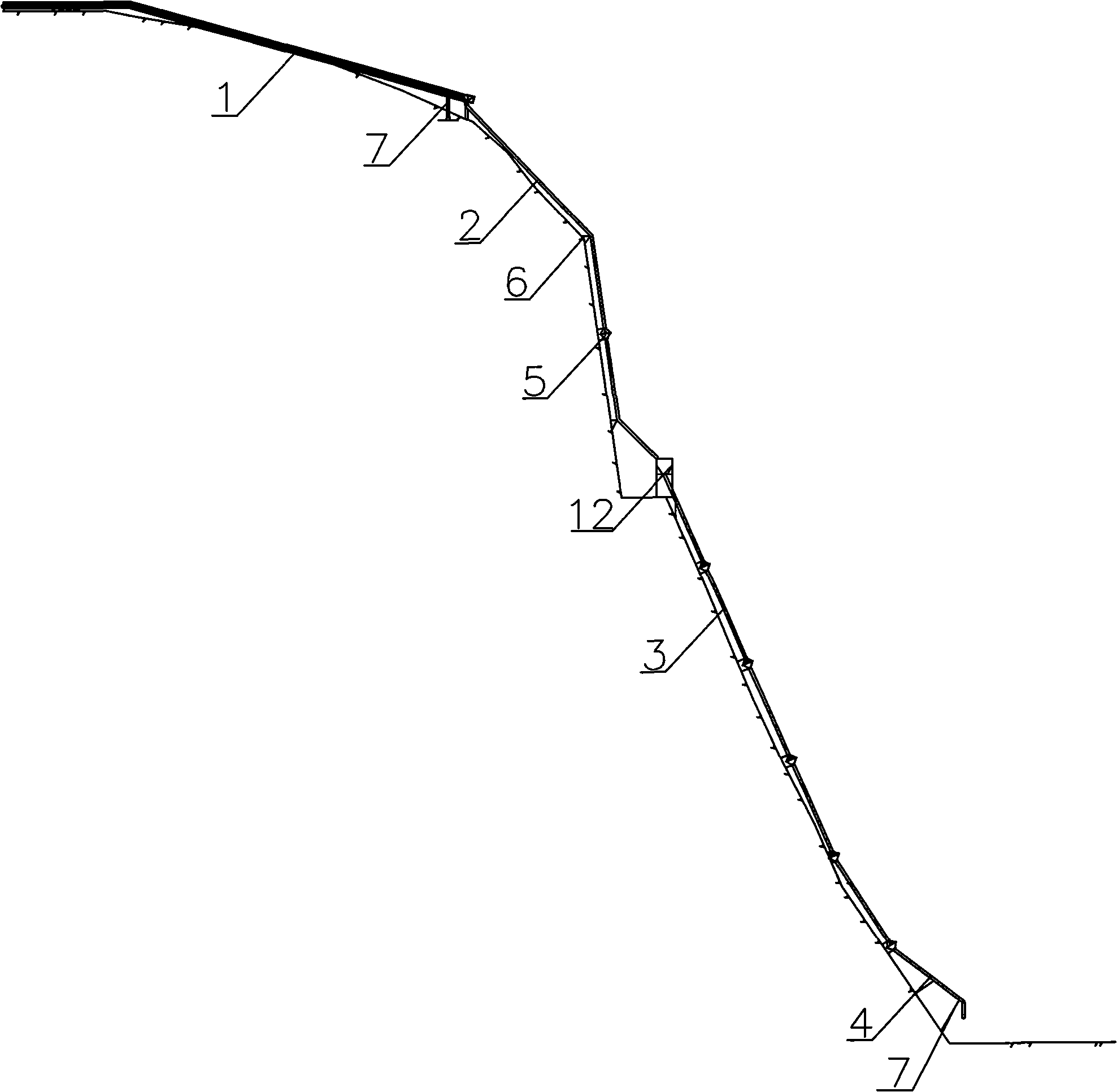

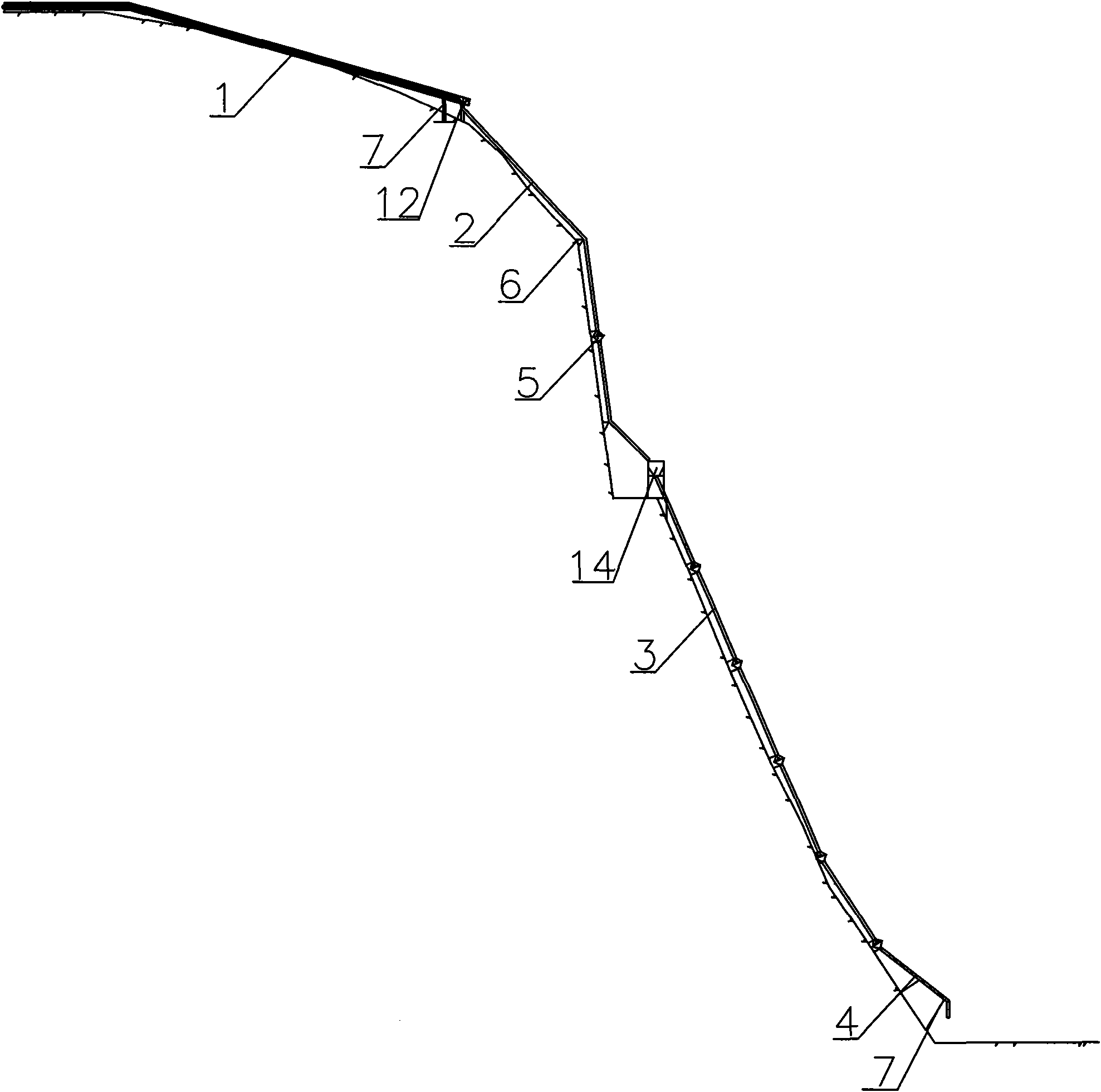

Vertical concrete conveying system of small and medium hydropower station at high steep slopes

A conveying system, small and medium-sized technology, applied in the field of concrete vertical conveying system of small hydropower stations, to achieve the effect of improving safety and stability, saving materials, and saving materials

Inactive Publication Date: 2010-08-25

CHINA GEZHOUBA GROUP CO LTD +1

View PDF1 Cites 13 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The technical problem to be solved by the present invention is to provide a vertical concrete conveying system for small and medium-sized hydropower stations with high and steep slopes, which can solve the problem of concrete transportation in environments with large angles, large drops, and high and steep slopes, save construction costs, and eliminate potential safety hazards during construction

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention discloses a vertical concrete conveying system of a small and medium hydropower station at high steep slopes, relating to a concrete conveying system. Through flexibly combining a belt conveying section, a chute conveying section, a chute barrel conveying section and an upright post chute conveying section, the concrete conveying system solves the problems of concrete conveying under the environment of large angles, great head drops and high steep slopes, and is in particular suitable for a concrete conveying task of a project in high-mountain gorge zones. Through improvement on the technology of the conventional concrete vertical conveying, the concrete vertical conveying system saves the materials, shortens the construction periods, reduces the construction difficulty and ensures the construction security.

Description

Concrete vertical conveying system for small and medium-sized hydropower stations with high and steep slopes technical field The invention relates to a concrete conveying system, in particular to a concrete vertical conveying system for small and medium-sized hydropower stations with high and steep slopes. Background technique When building dams or other projects in high mountains and valleys, due to terrain conditions, the use of cable cranes or tower cranes and vehicles to directly enter the warehouse, there are problems such as difficulty, a large amount of equipment to be invested, and a large amount of civil engineering, resulting in high construction costs. or unable to carry out construction. Chinese patent 200810048726.7 discloses "a method of conveying concrete on high and steep slopes and large drop terrain", which adopts a downward transportation system of concrete by its own weight in the environment of large angle, large drop, and high and steep slopes. This m...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): E02D15/02

Inventor 聂凯胡和平袁志新汤用泉朱志学刘经军

Owner CHINA GEZHOUBA GROUP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com