Dust control method for blasting demolition of building

A technology for buildings and blasting holes, applied in building construction, construction, building maintenance, etc., can solve the problems of surrounding environmental impact, inability to meet, difficult implementation process, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

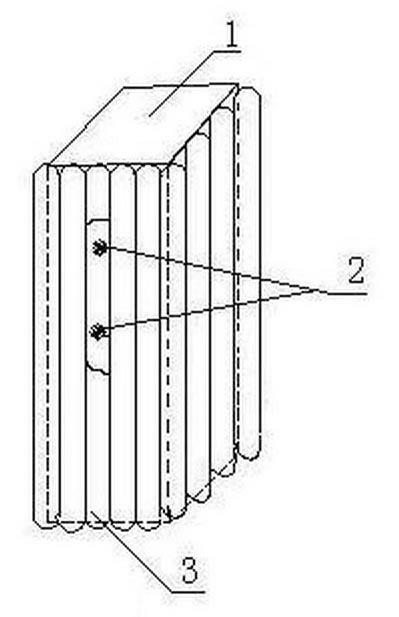

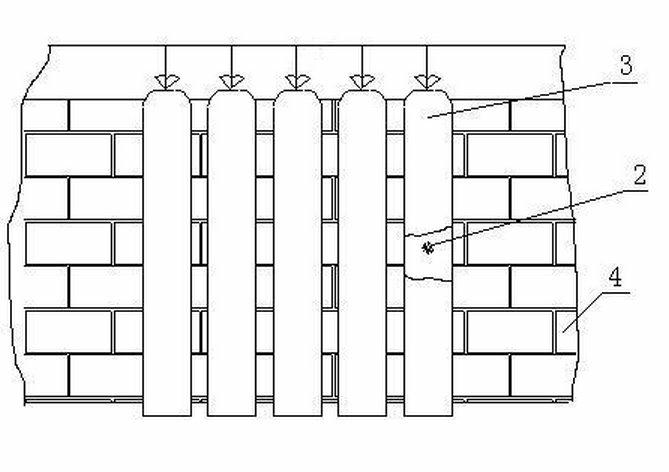

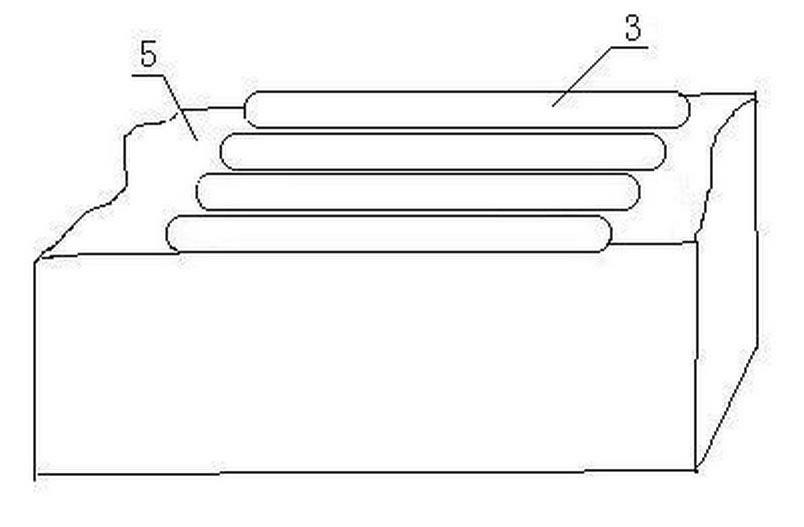

[0022] like figure 1 , figure 2 , image 3 As shown, there are column 1, wall body 4, beam 5 of blasting cutout for building, hang water bag 3 on blast hole 2 side and blast hole 2 periphery, use rope at three positions of water bag 3, middle and lower. Bundled and fixed, in order to facilitate fixing, the water bag 3 is cylindrical; the area where the water bag covers the blast hole 2 has a radius greater than 30 cm. For the load-bearing wall 4 without blasting cuts, it can only be placed above the blast hole 2 on both sides of the wall 4 and Water bag 3 is hung around the blast hole 2; the radius of the area covered by the water bag 2 is greater than 30 cm. For the beam 5 of a building without a blast hole, the water bag 3 is horizontally stacked on the upper surface of the blast hole 2 of the beam 5, and the water bag 3 Covering the blast hole 2 The radius of the area is greater than 30cm. In order to reduce the dust at the moment of floor blasting, a 13 cm high water p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com