Wood truss support structure for arch cap formwork of rigid frame arch bridge and construction method of wood truss support structure

A supporting structure and construction method technology, applied in bridges, bridge construction, erection/assembly of bridges, etc., can solve problems such as poor economy and inability to effectively ensure the quality of concrete molding, so as to improve the overall mechanical performance and reduce downside defects , Guarantee the effect of molding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

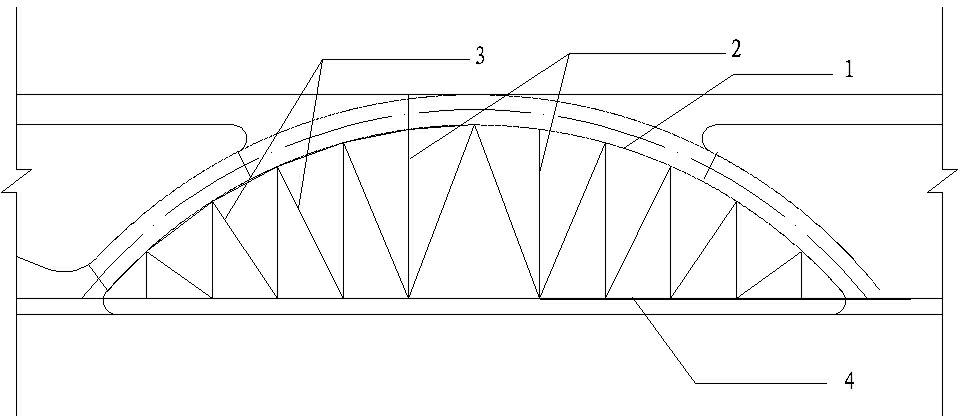

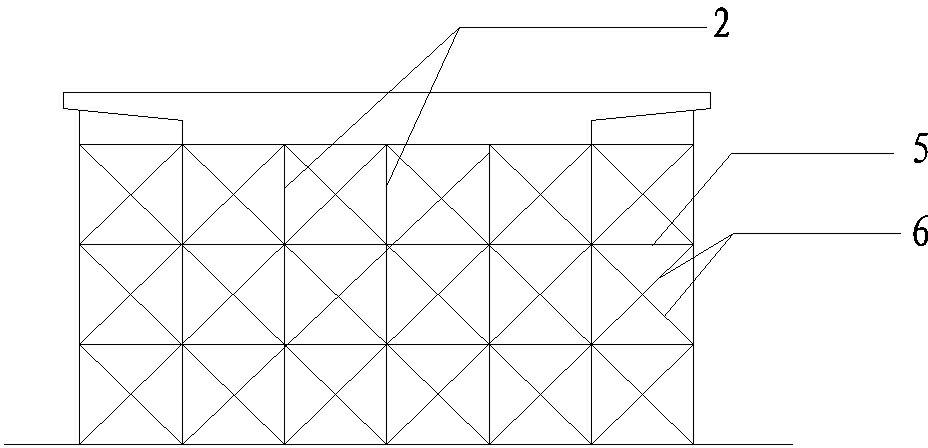

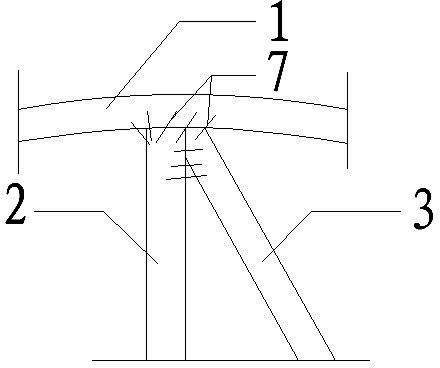

[0024] see Figure 1-3 , the present invention includes a lower suspension strut 4 and an upper suspension arc-shaped longitudinal beam 1 , and the two ends of the upper suspension arc-shaped longitudinal beam 1 are fixedly connected to the two ends of the lower suspension stay 4 . Several wooden uprights 2 are affixed between the lower suspension struts 4 and the upper suspension arc longitudinal beams 1 . Diagonal braces 3 are arranged between the wooden uprights 2 . After the splicing of each member of the truss, it is nailed on both sides with steel nails, and the lower suspension brace is supported on the foundation concrete. The lower suspension struts 4, the upper suspension arc-shaped longitudinal beams 1, the wooden vertical rods 2 and the diagonal braces 3 are fixedly connected to each other to form a truss with a multi-triangular stable structure. Horizontal tie rods 5 and scissors braces 6 are set between multi-truss trusses to form an integral structure, and squ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com