Preparation method of vermiculite-based high temperature-resistant sealing material

A sealing material and high-temperature-resistant technology, which is applied in the field of preparation of vermiculite-based high-temperature-resistant sealing materials, can solve the problems of flexible graphite gasket oxidation, weight loss of sealing materials, and reduced sealing performance, so as to facilitate dispersion, promote coating, and prevent The effect of reunion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

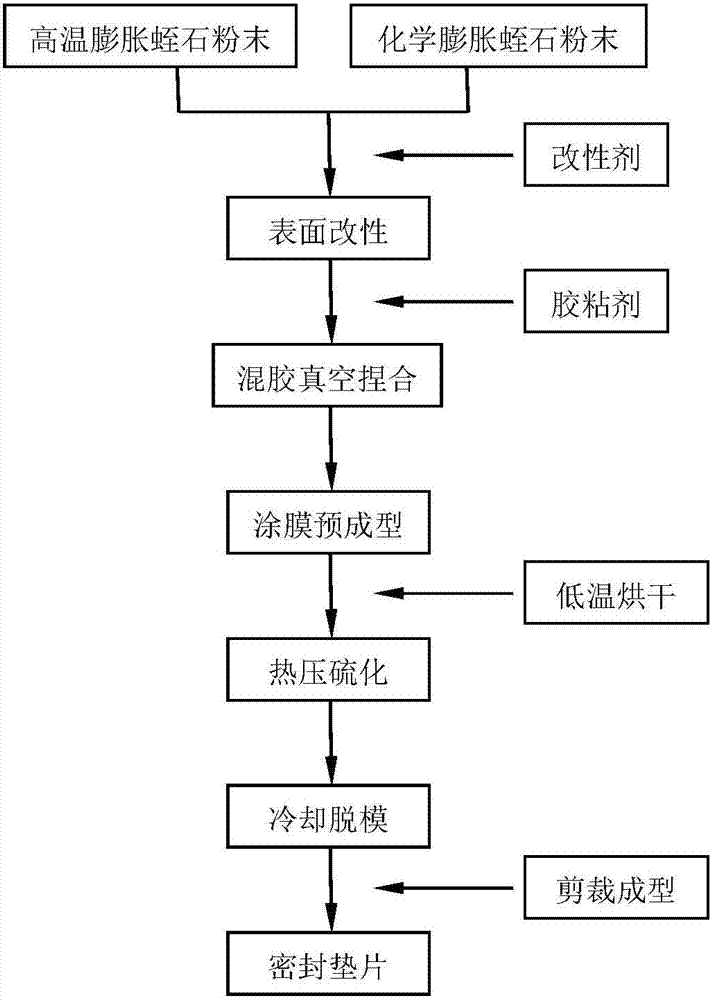

Method used

Image

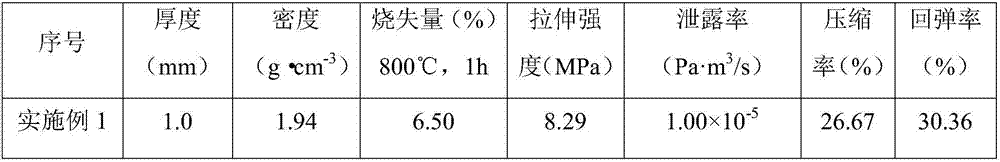

Examples

Embodiment 1

[0031] This example provides a preparation method for preparing a vermiculite-based high temperature resistant sealing material:

[0032] 1) Raw material formula

[0033] High-temperature expanded vermiculite powder 500g, chemically expanded vermiculite powder 500g, modifier vinyltriethoxysilane (A151) 5g, nitrile rubber 30g, vulcanizing agent dicumyl peroxide (DCP) 2.5g.

[0034] 2) Preparation process

[0035] Add water to adjust the concentration of the mixed material to 35%, send it into a vacuum kneader, add modifier A151 to modify at room temperature for 1.5 hours, add nitrile rubber and vulcanizing agent DCP, and vacuum knead for 1 hour to obtain a mixed vermiculite slurry, and then use an adjustable The film applicator preforms the slurry with a scraper, and controls the drying temperature at 65°C for 3 hours to obtain a vermiculite-based sealing material blank. The moisture content of the blank is 8%, and the preformed blank is placed on a flat vulcanizing machine fo...

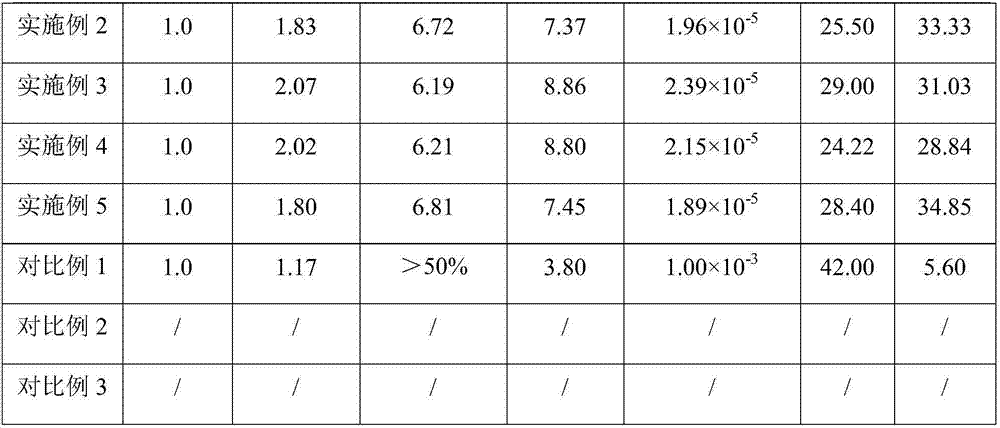

Embodiment 2

[0037] This example provides a preparation method for preparing a vermiculite-based high temperature resistant sealing material:

[0038] 1) Raw material formula

[0039] High-temperature expanded vermiculite powder 250g, chemically expanded vermiculite powder 750g, modifier γ-mercaptopropyltrimethoxysilane (A189) 10g, styrene-butadiene rubber 50g, vulcanizing agent sulfur 3g.

[0040] 2) Preparation process

[0041] Add water to adjust the concentration of the mixed material to 40%, send it into a vacuum kneader, add modifier A189 to modify at room temperature for 1.5 hours, add styrene-butadiene rubber and vulcanizing agent sulfur, and knead in vacuum for 1.5 hours to obtain a mixed vermiculite slurry, and then use Adjust the film applicator to preform the slurry with a scraper, and control the drying temperature to 70°C for 2.5 hours to obtain a vermiculite-based sealing material blank. The moisture content of the blank is 8%, and the preformed blank is vulcanized on a fla...

Embodiment 3

[0043] This example provides a preparation method for preparing a vermiculite-based high temperature resistant sealing material:

[0044] 1) Raw material formula

[0045] 750g of high-temperature expanded vermiculite powder, 250g of chemically expanded vermiculite powder, 20g of modifier γ-aminopropyltriethoxysilane (A1100), and 50g of organic silica gel.

[0046] 2) Preparation process

[0047] Add water to adjust the concentration of the mixed material to 45%, send it into a vacuum kneader, add modifier A1100 to modify at room temperature for 1 hour, add silicone rubber, and vacuum knead for 2 hours to obtain a mixed vermiculite slurry, and then use an adjustable film applicator to correct the slurry The material is preformed with a scraper, and the drying temperature is controlled at 75°C, and the drying time is 2h to obtain a vermiculite-based sealing material blank. The moisture content of the blank is 8%, and the preformed blank is vulcanized on a flat vulcanizing machi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com